How to check the motor of an Indesit washing machine?

If your washing machine refuses to start a cycle or spin the drum, a comprehensive diagnostic is required: from checking the electronics belt to the wiring and motor. It's best to consult a professional for the latter, but with the necessary experience and diligence, you can check your Indesit washing machine's motor without any special training. The main thing is to proceed carefully and follow the instructions.

If your washing machine refuses to start a cycle or spin the drum, a comprehensive diagnostic is required: from checking the electronics belt to the wiring and motor. It's best to consult a professional for the latter, but with the necessary experience and diligence, you can check your Indesit washing machine's motor without any special training. The main thing is to proceed carefully and follow the instructions.

Testing the engine

Once you decide to test the engine yourself, you need to carefully study the motor structure. Indesit washing machines are equipped with a collector-type motor, which is distinguished by its compactness and high power. An integral part of the device is the drive belt, which connects to the drum pulley and starts the rotation process.

As for the internal mechanism, several separate components are hidden under the housing: a rotor, a stator, and two electric brushes. A tachometer located on top monitors the speed in revolutions. Experts use several methods to check the motor's functionality. But first, you need to remove it from the washing machine.

- We remove the back panel of the washing machine by unscrewing the bolts around the perimeter.

- We loosen and remove the drive belt, while simultaneously rotating the pulley.

- We disconnect the supply line connected to the engine.

It is recommended to take photographs of the wiring before disassembling the machine to avoid errors during reassembly.

- We unscrew the retaining bolts and, rocking the engine from side to side, we take it out.

Now we begin diagnostics. Connect the wires from the stator and rotor windings, then apply 220 volts to them. If rotation is visible, the test has been successful, and the device is functioning properly.

However, the described testing tactic also has its drawbacks. For example, it's impossible to fully test the motor, especially if it will be operated in different modes. Another potential risk is overheating due to direct connection, which can cause a short circuit. However, the risk of failure can be easily reduced by adding a ballast, such as a heating element from a circuit breaker, to the circuit. The heater will heat up during a short circuit, absorbing the full load, thereby protecting the motor. However, this is only the first stage of testing, as other components of the electric motor—brushes, fins, and windings—are next in line.

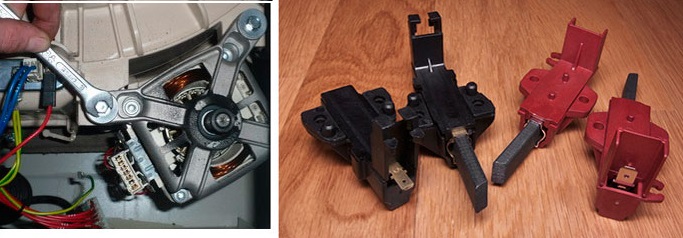

Let's check the condition of the brushes

Be sure to pay attention to the brushes. They are located on both sides of the housing and smooth out the friction force emanating from the motor. The impact is absorbed by carbon tips, which wear out over time and require replacement. To check them, follow these steps:

- unscrew the retaining bolts.

- We compress the spring and remove the brushes.

- We disassemble the body of each brush.

- We assess the condition of the carbon tips. If their length is less than 1.5 cm, we replace them with new ones.

Electric brushes are always replaced in pairs, even if one of them is brand new.

If the brushes are worn out, you need to buy new ones. Ideally, you should take old samples to the store and buy similar parts. The electric brushes are installed in reverse order according to the already familiar instructions.

Lamels and windings

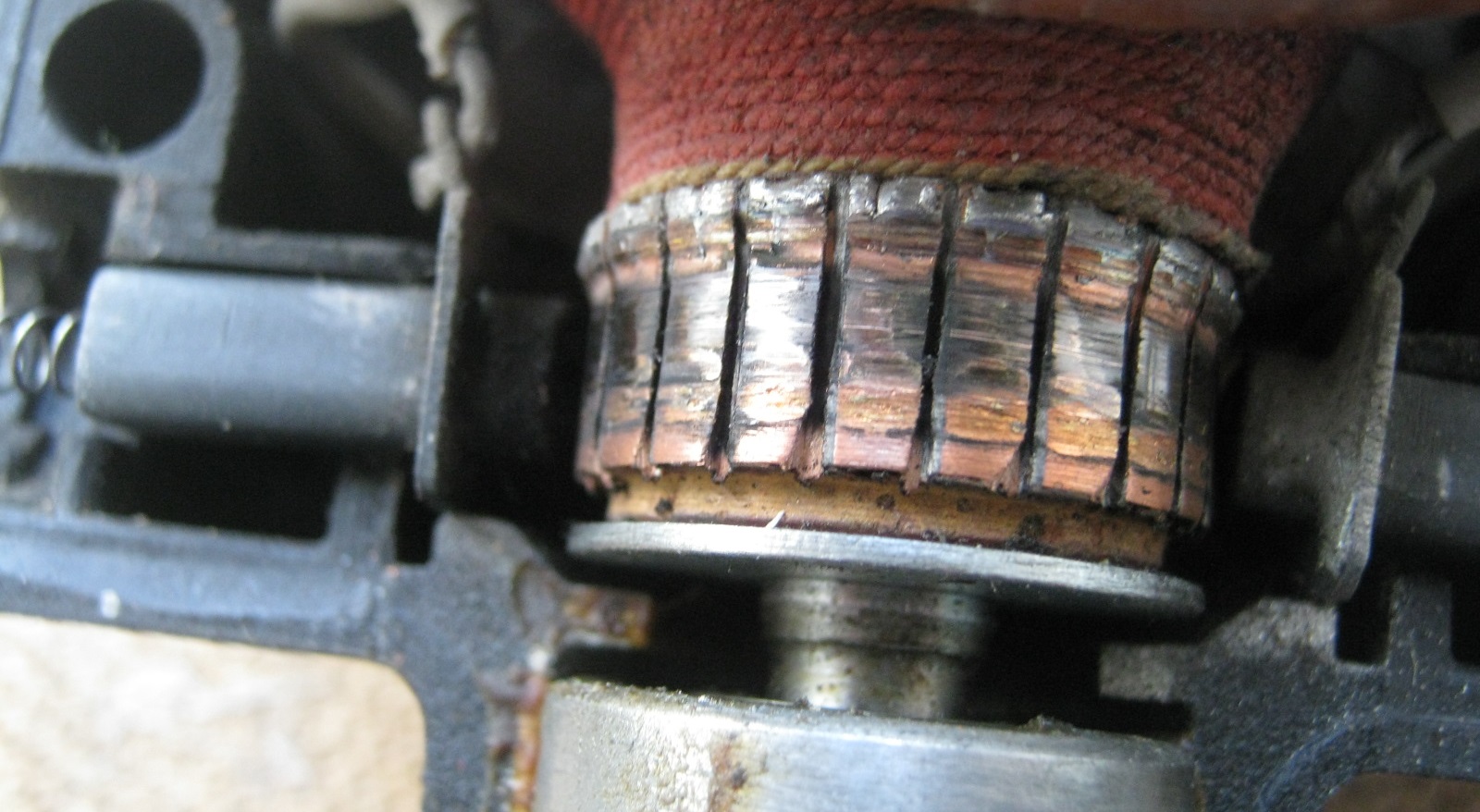

The lamellas are responsible for transmitting the electrical charge to the rotor. They are glued directly to the shaft, but if the electric motor seizes, they can break and peel off. If the peeling is minor, you can avoid replacing the motor by using a lathe and fine sandpaper.

Damaged lamellas have delamination and burrs.

If there's a problem with the winding, the engine either can't reach its maximum speed or won't start at all. This is because a short circuit occurs, causing the motor to overheat. The temperature sensor detects the overheating and shuts down the system immediately. If the problem is not corrected, the vicious circle will continue until the thermistor breaks. The condition of the winding is checked with a multimeter.

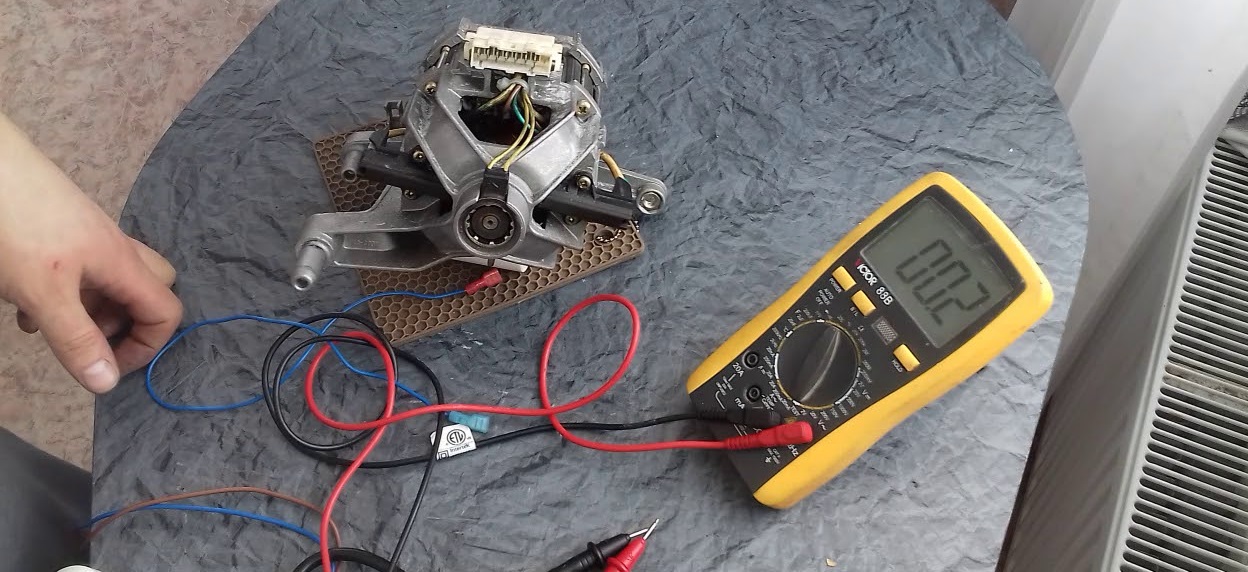

- The tester is switched to the “Resistance” mode.

- The feeler gauges are applied to the lamella.

- The value on the display is evaluated, which is normally 20-200 ohms. A lower value indicates a short circuit, while a higher value indicates an open circuit.

The stator is also checked with a multimeter in buzzer mode by alternately touching the probes to the winding. If the device remains silent, everything is fine. If you discover a problem with the winding, don't rush to repair the motor—it's useless. It's easier and cheaper to buy a new motor.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment