How to test a washing machine capacitor with a tester?

It's fairly easy to tell if something is wrong with an electric motor's starting capacitor. The malfunction can be detected visually—the part's casing is deformed and bulges at the top. In some cases, the device may appear normal, so you'll need to test it with a multimeter. Let's see how.

It's fairly easy to tell if something is wrong with an electric motor's starting capacitor. The malfunction can be detected visually—the part's casing is deformed and bulges at the top. In some cases, the device may appear normal, so you'll need to test it with a multimeter. Let's see how.

Testing a polar element

How to test a washing machine capacitor with a multimeter? You can do the job yourself at home. Diagnostics of starting devices should be performed by removing them from the electrical circuit. This allows you to get more accurate readings.

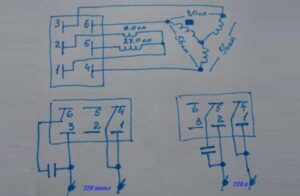

An automatic washing machine can be equipped with a polarized or non-polarized capacitor. When testing a polarized device, one important condition must be met: its capacitance must be greater than 0.25 μF. Let's look at how to test this component with a tester.

The technology for diagnosing a polar capacitor with a multimeter will be as follows:

- Short-circuit the capacitor with tweezers, a fork, pliers, a screwdriver, or another metal object. This is necessary to discharge the device. If done correctly, a spark will appear;

- switch the tester to ohmmeter mode;

- Place the multimeter probes against the capacitor contacts, remembering to take into account the polarity;

- evaluate the readings on the device display.

When diagnosing a polar capacitor, the red multimeter probe is connected to the positive terminal and the black probe to the negative terminal.

If the tester beeps and the display shows "0," there's a short circuit. This is what caused the capacitor to fail. A "1" displayed on the multimeter immediately after connecting the probes indicates an internal open circuit. In both cases, the starting device will need to be replaced.

It's crucial to perform diagnostics correctly, otherwise the device's readings may be inaccurate. For example, do not touch the probes during measurements. The human body has low resistance, so current will "flow" past the capacitor, and the multimeter will show completely different values.

Discharging a capacitor is essential before diagnosing it, especially if the device is high-voltage. This is done, firstly, for safety reasons and secondly, to avoid damaging the multimeter. The tester can burn out if the residual voltage of the element is high.

Testing a non-polar element

Non-polarized starting devices are even easier to test with a tester. First, set the multimeter to megaohms. Then connect the probes to the capacitor's terminals. If the display shows a value of less than 2 mOhms, the element is faulty.

When testing single-pole capacitors, there is no need to adhere to polarity.

If you need to test a non-polarized capacitor with a voltage over 400 volts, this can be accomplished by charging it with a device protected against short circuits. A resistor with a minimum resistance of 100 ohms is connected in series with the capacitor. This precaution will prevent a sudden current surge during startup.

Another method for testing a single-pole starting device is to check for a spark. The component must be charged to its working capacity. Then, the contacts must be shorted using a suitable tool with an insulated handle (pliers or a screwdriver). A strong discharge will indicate the component's functionality. After a spark appears, the resistance at the capacitor's terminals is measured with a tester.

Checking the capacity

One of the key characteristics of a capacitor is its nominal capacitance. Over time, this value can decrease, meaning the device will accumulate less charge and retain it less effectively. To check the functionality of the starting element, the capacity is measured and compared with the value marked on the housing. The procedure has some specific features.

So, using a standard, inexpensive multimeter, you won't be able to quantitatively measure the capacitance of a capacitor. You can only confirm that the device is working. To test the element, the tester is set to continuity mode.

After touching the capacitor's legs with the probes, you should hear a characteristic sound. Then, swap the multimeter leads, and the beeping should repeat. This will be audible if the starting device's capacitance is greater than 0.1 μF.

The larger the working capacity of the capacitor, the longer the multimeter will “beep” when ringing the starting device.

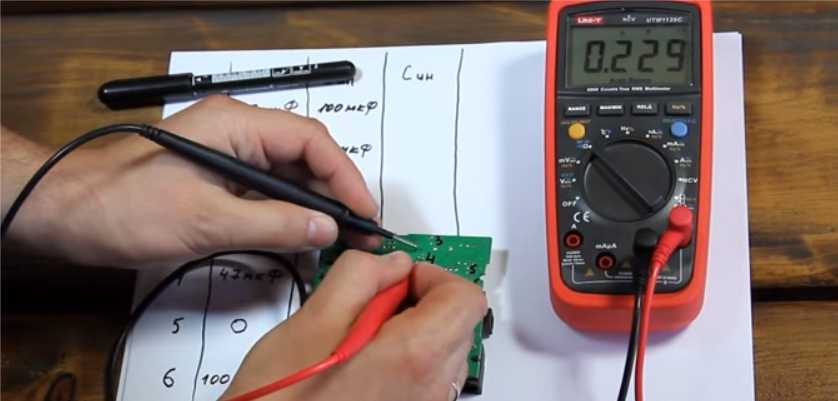

To obtain accurate results, you'll need a more professional multimeter with specialized connectors and the ability to adjust the fork to calculate the device's capacitance. Before beginning diagnostics, such a tester should be set to the nominal value indicated on the starting capacitor's casing.

Next, the capacitor is discharged with metal. Its legs are then inserted into the special "sockets" provided on the multimeter. The tester's screen should display a capacitance value that matches the nominal value, with a slight deviation allowed. If the reading deviates significantly from the norm, the starting device is damaged.

Is the voltage correct?

Another way to verify that the capacitor is working is to measure its voltage and compare the resulting value with the rated value. A power source will be required during this test, and its voltage must be lower than that of the starting device being tested.

For example, if the capacitor is rated at 25 volts, a 9-volt power source will suffice. Next, set the tester to ohmmeter mode, connect its probes to the element's terminals, observing polarity, and wait about 5 seconds.

The tester screen should display the capacitor voltage. If the value matches the standard, the starting device is working properly. Otherwise, the element will need to be replaced.

Advice from experts

When testing capacitors, technicians face a particular challenge. During soldering, even a initially functional component can be damaged by heat. However, for a thorough diagnosis, the starting device must be removed from the circuit to avoid being bypassed by nearby sensors. Therefore, several nuances must be taken into account.

Once the tested starting device is soldered into the circuit, start the washing machine being repaired. If the machine's functionality is restored, it's best to remove the old capacitor again and install a new one.

Another recommendation is to reduce testing time and the risk of damaging the capacitor by desoldering only one leg, rather than both. However, this option is not suitable for all electrolytic cells. Therefore, first consider whether this method is feasible in your case.

If the circuit is complex and contains a large number of capacitors, it's best to check the voltage of each component without removing it to locate the faulty component. A starting device whose parameters don't match the rated values should be desoldered and replaced with a new one.

If you find that the circuit is "failing", you need to check the production date of each starting device. Capacitors tend to "dry out" over time, so even if the element is in good working order, but was manufactured 5-7 years ago, it needs to be replaced with a new one. On average, over 5 years, the shrinkage of a part is approximately 65%, which causes the circuit to malfunction.

It's important to understand that modern, next-generation multimeters can only test capacitors up to 200 μF. If the value is higher, the tester will fail. Even the included fuse won't save the device.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment