How to check the motor of a Zanussi washing machine?

If your Zanussi washer fills with water and stops after starting a program, there's a problem with the drive. Simply put, the washing machine can't spin the drum and begin a full wash cycle. It's impossible to immediately determine the cause of the stoppage: a slipped belt, a faulty motor, or the control board could all be causing the stall.

If your Zanussi washer fills with water and stops after starting a program, there's a problem with the drive. Simply put, the washing machine can't spin the drum and begin a full wash cycle. It's impossible to immediately determine the cause of the stoppage: a slipped belt, a faulty motor, or the control board could all be causing the stall.

Testing the control module yourself at home is risky and dangerous, but checking a washing machine's motor is entirely possible. Now, let's figure out where to start and how to proceed.

We remove and test the electric motor

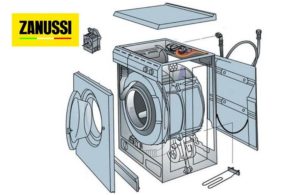

Diagnosing a Zanussi washing machine motor is not easy, but even a novice can handle it. However, it's best to start with theory: learn the machine's design and determine the type of motor installed. As a rule, even modern Zanussi machines are more likely to use brushed motors, which are more cost-effective and less problematic than inverter motors. The distinctive feature of the collector is the drive belt, which ensures the rotation of the drum.

Before repairing Zanussi, it is necessary to de-energize and disconnect it from the water supply.

As for the motor's internal structure, everything is standard here too: a rotor, a stator, a shaft with fins, and a winding. On top is the housing, which houses the electric brushes and the tachogenerator. The latter, called a Hall sensor, monitors the engine's RPM.

Having studied the motor's design, we can begin diagnosing it. But first, remove the device from the Zanussi housing according to the following instructions:

- find a bolt on the side wall;

- Use a screwdriver to pry up the plug that hides the bolt, exposing the fastener;

- unscrew the screw;

- repeat the procedure with the screw on the second side panel;

- unscrew the bolts holding the top cover of the case (the screws are located at the back behind the cover protrusion on the plastic lugs);

- remove the "top";

- unscrew the screws located on the top of the housing on the crossbar (stiffener);

- remove the drain hose from the rear panel;

- disconnect the element with the power cord from the back by bending the locking tab;

- loosen the back from the bolts and remove it;

- remove the drive belt from the pulley;

- locate the motor located under the drum;

- disconnect the wiring connected to the motor;

- Unscrew 4 screws and, after shaking it, remove the engine from the machine.

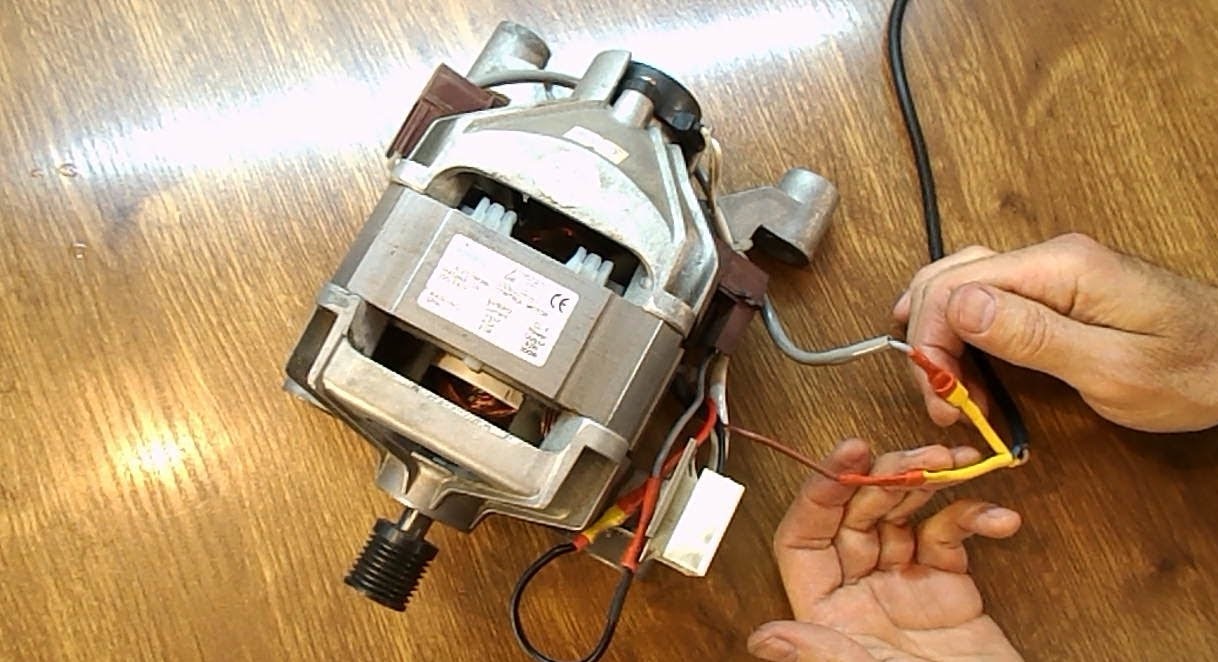

Place the removed motor on a table and begin diagnostics. Take a two-wire cable with a cross-section of at least 2.5 mm, run it from the rotor to the stator, and connect it to a 220 V power source. If the device hums after applying voltage, the motor is running; if the device remains motionless, it needs to be replaced.

Before beginning testing, it's worth considering the risks. Firstly, this type of testing is superficial and can't assess the motor's performance at different speeds. Secondly, connecting directly to the power grid is quite dangerous, as it can cause the device to overheat. To be on the safe side, it's necessary to include a stabilizer, such as a heating element, in the circuit. In the event of a current leak or sudden surge, the heater will absorb the shock, and the motor will remain undamaged.

Zanussi motor diagnostics don't end there. It's also advisable to check the system's key components separately—the brushes, fins, and winding.

Assessing the condition of electric brushes

The first thing to check is the brushes. They are the most common cause of motor slowdown. These are rectangular metal "casings" containing spring-loaded graphite rods. The "carbons" smooth out the friction generated by the device while simultaneously wearing down. If the tips are not long enough, the engine will overheat and malfunction.

The first thing to check is the brushes. They are the most common cause of motor slowdown. These are rectangular metal "casings" containing spring-loaded graphite rods. The "carbons" smooth out the friction generated by the device while simultaneously wearing down. If the tips are not long enough, the engine will overheat and malfunction.

Diagnosing brushes involves measuring their length. Here's how:

- we unscrew the screws holding the cases;

- we clamp the spring and remove the rods;

- let's cut each case in half;

- We take out the tip and measure it.

Electric brushes are changed in pairs!

The minimum length is 1.5-2 cm. If the "carbon" is shorter on at least one brush, both brushes must be replaced. Brush refills are selected based on the serial number of the motor or the Zanussi brush itself. The best option is to remove the old brush refills and match them to the original.

We climb into the electric motor housing

The lamellas are also a must-check. These are metal plates glued to the shaft, which transmit the required voltage to the rotor. Over time, they can peel off, impeding current flow. If the peeling is minimal, repairs can be done with just sharpening. Severe deformations cannot be corrected unless the entire motor is replaced.

The lamellas are also a must-check. These are metal plates glued to the shaft, which transmit the required voltage to the rotor. Over time, they can peel off, impeding current flow. If the peeling is minimal, repairs can be done with just sharpening. Severe deformations cannot be corrected unless the entire motor is replaced.

If the winding breaks, the motor also stops running. This causes a short circuit, which leads to motor overheating, thermistor activation, and an emergency power outage. For diagnostics, it is necessary:

- take a multimeter;

- turn on the ohmmeter;

- place the feeler gauges against the shaft;

- evaluate the indicators (normal - from 20 to 200 Ohm).

Control board diagnostics should only be performed at a service center!

Finally, we test the stator by connecting a buzzer. If the device shows a broken winding on the Zanussi, the motor will need to be replaced.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

I have a 9-pin connector. Two, as far as I understand, are the tachometer, two are the thermal, two are the brushes, and three are the continuity test contacts with absolutely identical resistance. Where are the ends of the windings?