Checking the washing machine's tachometer

The Hall sensor ensures smooth communication between the motor and the control system. This tiny component, complete with wires, monitors the drum's speed and accelerates or decelerates it. If the washing machine suddenly slows down, doesn't stop, or produces completely wet clothes at the end of the cycle, it's time to check the washing machine's tachometer. All that's left to do is find the part and test it for proper operation.

The Hall sensor ensures smooth communication between the motor and the control system. This tiny component, complete with wires, monitors the drum's speed and accelerates or decelerates it. If the washing machine suddenly slows down, doesn't stop, or produces completely wet clothes at the end of the cycle, it's time to check the washing machine's tachometer. All that's left to do is find the part and test it for proper operation.

Signs of sensor failure

The need to check the Hall sensor most often arises due to malfunctions in the washing machine. Being one of the most important components of the system, a faulty tachogenerator immediately signals problems with the RPM control. Thus, problems with the drum rotation can be suspected by the following distinctive signs:

- the machine changes speed mode abruptly, sometimes accelerating, sometimes slowing down, regardless of the stage of the cycle;

- the speed gained is several times higher than the mark set by the user or the system (often even exceeding the maximum permissible value);

- the drum does not spin up to the required speed or does not spin at all;

- the items are not wrung out or washed.

To rule out a temporary system failure or accidental spin shutdown, turn off the washing machine and start a standard cycle after 20 minutes.

These are just the initial stages of a machine with a faulty tachogenerator. Subsequently, the washing machine will refuse to start a cycle and display an error message. In the worst case, the motor will burn out. There's no time to delay solving the problem, so at the first sign of a faulty Hall sensor, we begin testing.

Where to look for the part?

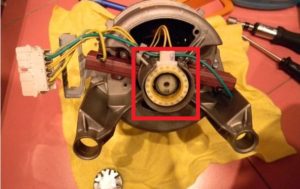

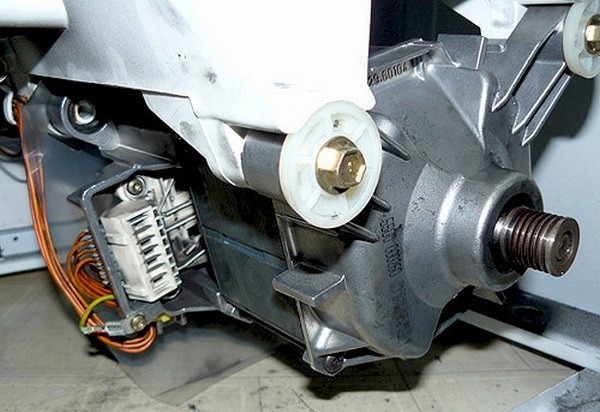

Before checking the sensor, you need to locate it. This isn't difficult, as it's located in the same place on all washing machine models and brands—on the rotating motor shaft. To access it, you'll need to partially disassemble the machine: remove the rear panel of the machine housing and the drive belt.

Before any manipulation, disconnect the machine from the power supply and turn off the water supply tap.

Next comes the motor. Look for a small iron ring on the shaft – this is the tachogenerator. Don't just remove it; the entire motor must be removed. Electrical installation experience is essential here: if you don't have it, it's best to entrust the service to a qualified technician. Experimenting with the washing machine's internals is not recommended – there's a high risk of aggravating the situation and bringing the unit to the point of no return or costly repairs.

Checking the sensor

If you decide to remove the motor and test the Hall sensor yourself, follow the instructions carefully. But first, label the wiring connected to the electric motor or take photos of everything with a camera. This will help avoid mistakes when reconnecting the motor. Then, proceed as methodically as possible.

- We unscrew the bolts holding the engine.

- We shake the engine from side to side, and then pull it sharply towards ourselves.

Be prepared for the engine to be very heavy.

- We inspect the sensor and wires for integrity and secure attachment. It's likely that the sudden speed changes have caused the contacts to come loose or the clamps to become loose. In this case, all that remains is to restore the original balance by tightening the terminals.

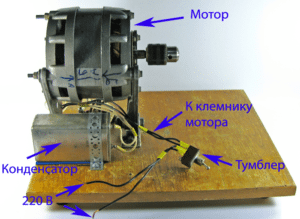

If there are no visible damage or deviations, testing is necessary. This can be done in two ways. In the first case, set the multimeter to measure ohms, loosen the wiring, apply the probes to the contacts, and evaluate the result. A reading of 60-70 ohms indicates the sensor is working properly.

Another option is to measure the current generated by the tachogenerator. Set the tester to voltage mode, connect the probes to the contacts, and use your free hand to accelerate the electric motor. It is important here that a figure of about 0.2 Volts appears, which will prove the working condition of the device.

In practice, the tachogenerator rarely fails, and most often, drum rotation interruptions are caused by faulty wiring and the control board's triacs. You can check the integrity of the wiring yourself by looking for signs of burning, pinched, or loose contacts on the visible cables. It is strongly recommended not to attempt to repair the control module yourself—it is cheaper and more reliable to contact a service center immediately.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment