How to determine the starting and running windings of a washing machine motor?

If your washing machine's motor is acting up, you'll need to diagnose it. To check the motor, let alone repair it, you need to know how it works. It's best to start with the basics, such as figuring out where to find the washing machine's motor windings and how to avoid mixing them up. It's actually quite simple; even a novice can handle this task.

If your washing machine's motor is acting up, you'll need to diagnose it. To check the motor, let alone repair it, you need to know how it works. It's best to start with the basics, such as figuring out where to find the washing machine's motor windings and how to avoid mixing them up. It's actually quite simple; even a novice can handle this task.

Learning to distinguish windings

Washing machines of medium power are equipped with single-phase electric motors. These motors have a starting and a working winding, which ensure the rotation of the rotor. Engines of this type can be conditionally divided into two subgroups:

- single-phase devices with starting winding;

- electric motors with a working capacitor.

In the first case, the motor's starting winding operates for only 3-5 seconds, only after the engine is activated. Once the rotor reaches its optimal speed, it is disconnected from the power supply. The electric motor continues to operate with only one mains winding.

In single-phase motors with a capacitor in the circuit, the starting winding is constantly active. The nominal capacitance of the capacitor will be determined by the power and other characteristics of the electric motor.

Therefore, if the motor's auxiliary winding is a starting winding, it will only operate for a few seconds, immediately upon starting the motor. If it's a capacitor winding, it will remain active until the motor is disconnected from the power supply. This is the main difference.

Knowing the structure of the two types of windings in a single-phase washing machine motor is essential if you plan to repair the motor yourself. The starting and working windings are easily distinguished from each other by the cross-section of the wires and the number of turns.

The working winding of the motor is characterized by a larger wire cross-section, therefore the resistance it produces is less.

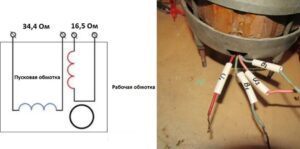

Looking at the diagram, it's easy to identify the starting and running windings (left and right, respectively). It's easy to see that the wire cross-sections are significantly different. Their resistance is measured with a special tester—a multimeter. This device can be purchased online or in specialized stores.

Practical examples

In practice, after disassembling a washing machine and removing the motor, you may encounter a number of questions. Therefore, let's look at a few examples that clearly demonstrate how to measure the resistance of electric motor windings.

Let's say the motor removed from the washing machine has 4 terminals. Find the ends of the windings and measure the resistance with a tester. The values on the multimeter screen make it easy to determine which winding is which: the one with the lower ohms is the working winding, and the one with the higher ohms is the starting winding.

Wiring everything up is quite simple. 220 volts are applied to the thick wires. One end of the starting winding is connected to the end of one of the working wires. It doesn't matter which wire is connected; the direction of the rotor rotation won't change. The direction of rotation will change only when the ends of the starting winding are swapped.

Another example is if the motor has three terminals. Measuring the resistance of each terminal usually yields the following values: 10 ohms, 25 ohms, and 15 ohms. By trial and error, find the "tail" of the winding wire that, when connected to the others, shows a reading of 10 ohms and 15 ohms on the multimeter.

This wire will be one of the working wires. The tip, which, when paired with it, produces a resistance of 10 ohms, will also "belong" to the network winding. The remaining third wire is the starting wire; it is connected to the circuit via a capacitor.

Sometimes, when measuring the resistance of the motor terminals, the multimeter displays values of 10, 10, and 20 ohms. This is an example of another type of winding. They are found on certain models of automatic washing machines. In this case, the cross-section of the working and starting wires will be the same, making it impossible to visually determine which is which.

There's no real difference between which wire goes where. The starting winding in these motors is energized through a capacitor of the appropriate capacity.

Determining the starting and running windings of a single-phase electric motor is actually quite simple. In some cases, this can be done visually, while in other situations, a multimeter is required.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment