How to disassemble a non-detachable drum in a Candy washing machine

Sometimes, during repairs, it may be necessary to disassemble the drum of a Candy washing machine. This is usually necessary if the bearings and seals hidden inside the machine are damaged. The Italian brand's washing machines are equipped with non-detachable drums, which significantly complicates the work.

Sometimes, during repairs, it may be necessary to disassemble the drum of a Candy washing machine. This is usually necessary if the bearings and seals hidden inside the machine are damaged. The Italian brand's washing machines are equipped with non-detachable drums, which significantly complicates the work.

Is it possible to disassemble a non-detachable drum yourself? What tools will you need? How will you reassemble the structure so it remains airtight? Let's explore the nuances.

Let's take the drum out of the machine body.

The steps for removing the tank are the same for all Candy models. The only significant difference is when working with front-facing and vertical-facing models. In the former case, you'll need to remove the front panel of the case, while in the latter case, you'll need to remove the side panel.

To disassemble the washing machine and separate the drum, you will need the following tools:

- Phillips and slotted screwdrivers;

- screwdriver;

- hacksaw or grinder;

- drill 3-5 mm;

- punch;

- hammer;

- pliers;

- set of socket heads;

- ratchet wrench.

It is better to take photographs of all disconnected contacts and electrical diagrams in order to correctly connect the wiring during the assembly stage.

To easily disassemble a washing machine, you'll need 2-3 square meters of space. Therefore, place the appliance in the center of the room to ensure access to all sides of the unit. It is necessary to disconnect from the tank all elements that will interfere with its removal. Algorithm of actions:

- Disconnect the machine from the power supply by pulling the power cord out of the socket;

- close the shut-off valve that supplies water to the washing machine;

- disconnect the inlet and drain hoses from the washing machine body;

- Unscrew the two bolts holding the top cover of the front camera;

- remove the top panel of the machine;

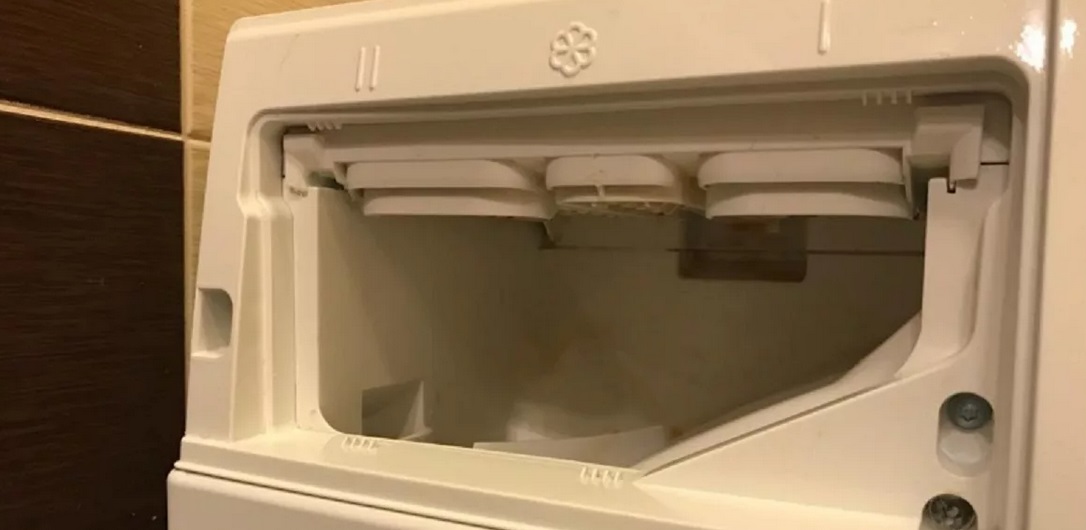

- remove the detergent dispenser;

- remove the bolts around the perimeter of the control panel;

- carefully disconnect the dashboard and place it on the machine (there is no need to disconnect the wires from the electronic module – the panel will not interfere with removing the tank);

- Use a screwdriver to pry up the spring of the clamp holding the drum cuff and remove the metal ring from the washing machine;

- tuck the sealing cuff inside the drum;

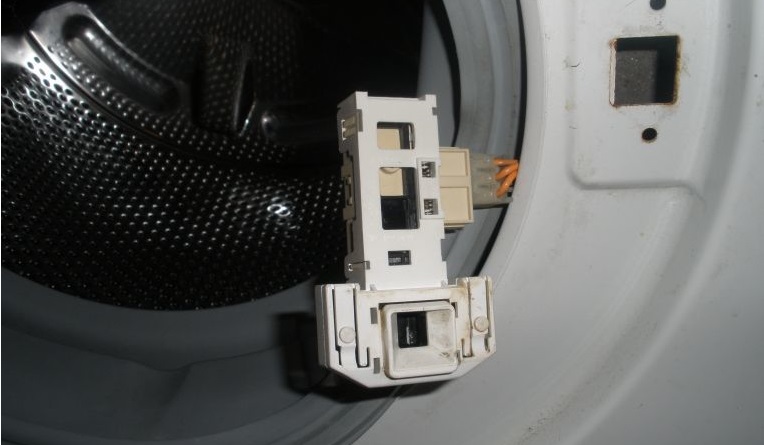

- unscrew a couple of screws securing the door lock;

- remove the wiring from the blocker and pull out the locking device;

- remove the lower false panel by prying it up with a slotted screwdriver;

- Place a container in the area where the drain filter is located and unscrew it from the machine (you need to wait until all the water accumulated in the system flows out into the basin);

- remove the screws around the perimeter of the front panel of the washing machine, detach the wall and put it aside;

- remove the rear panel of the case by removing the mounting screws;

- remove the wiring from the heating element;

- loosen the central nut of the heating element and remove the heater from the socket;

- remove the counterweights adjacent to the tank;

- remove the drive belt;

- disconnect the wiring from the engine;

- Disconnect the drain pipe from the tank.

Now that all the parts are removed from the tank, nothing is blocking the container's removal. You can begin loosening the shock absorbers. Unscrew the suspension spring clamps and remove the tank-drum assembly from the housing. Place the complete assembly on a flat surface.

Separating the plastic tank from the metal drum

Many automatic washing machines feature a non-detachable drum. This reduces the cost of the washing machine. Cast drums eliminate additional bolts and fasteners, reducing production costs.

The emphasis is also on the subsequent sale of components. For example, if bearings fail, many users will not "cut" the tank but will buy the complete assembly. This represents additional revenue for the manufacturer.

Experts have long since devised a way to separate a non-separable tank and reassemble it without losing its seal. The plastic container is "cut" with a hand saw. Generally speaking, the procedure is as follows:

- mark holes on the side of the tank at intervals of 5-7 cm (they will be needed to reassemble the structure)

- drill holes;

- carefully cut the tank along the factory seam;

- Using a punch and a hammer, knock out the old bearings;

- install new components;

- assemble the tank.

Overall, the outlined plan is fairly simple. However, in reality, the work ahead is meticulous. Not only will the tank need to be carefully separated to ensure easy reassembly, but the bearings will also need to be pressed out and new rings installed. Therefore, let's examine each stage of the process in more detail.

To begin, wipe the tank with a clean, damp cloth and mark the holes along the perimeter of the factory weld. The holes should be spaced 5-7 cm apart. The drill bit should be 3-5 mm in diameter.

Next, arm yourself with a hacksaw and carefully cut the tank along the seam. The rear section of the structure contains the drum, bearings, and seal. Therefore, further work is performed on this "half-tank."

Now you need to remove the drum from its plastic half. To do this, unscrew the pulley and knock out the shaft. The next step is to remove the broken bearings.

The drum bearings are knocked out with a punch and a hammer; the tool is placed on the inner race of the ring.

Each bearing is tapped in a circle. Sometimes the parts are stubborn; in this case, it's recommended to spray them with WD-40 and leave them for 15 minutes. This will make removing the bearing rings easier.

Once you've finished pressing out the bearing, clean the bearing seat of any dirt. The drum shaft should also be wiped and polished. After that, you can install the new bearings.

Rings are always replaced in pairs. A new sealing rubber is also always installed. Before installation, the bearings and seal are generously treated with a special lubricant.

After lubricating the bearing, place it in the bearing seat and press it in with a drift. Tap the element along the outer edge. When the ring is fully seated and rests against the flange, a characteristic dull sound will be heard.

The oil seal is placed on the inner bearing. The sealing rubber should be generously coated with grease—it's difficult to overdo it. The silicone will prevent water from entering the unit, thereby extending the life of the new parts.

Next, you need to secure the drum to the rear tank. Replace the pulley and tighten the screw. To "glue" the two halves of the plastic tank together, you'll need a high-quality, moisture-resistant silicone sealant.

Apply sealant around the perimeter of the halves and join the parts. The drilled points will serve as screws to secure the two half-tanks together. Now you can begin reassembling the machine – replace the plastic container and connect the heating element, motor, and drain hose to it. Then install the rear and front panels, dashboard, debris filter, and other components.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Your video is very useful, thank you.