How to cut the drum of an Indesit washing machine?

The question of how to separate the drum of an Indesit washing machine is often asked by users who need to replace the bearings on their machine. In fact, the stainless steel drum cannot be cut. Instead, the plastic, non-detachable tank containing the drum must be cut. By separating the tank into two halves, you can access the bearings, seal, and spider.

The question of how to separate the drum of an Indesit washing machine is often asked by users who need to replace the bearings on their machine. In fact, the stainless steel drum cannot be cut. Instead, the plastic, non-detachable tank containing the drum must be cut. By separating the tank into two halves, you can access the bearings, seal, and spider.

Craftsmen are familiar with the technology for cutting washing machine tubs, but even experienced specialists spend varying amounts of time on the job. Some will need 1-1.5 hours, while others may spend up to 3 hours. Let's look at the fastest and most convenient cutting methods that will get the job done in the shortest possible time.

What tools to use?

The speed of the job depends largely on the tools used. A hacksaw is considered the simplest tool. Its major drawback is the difficulty of cutting. Armed with a hacksaw, it would take hours to cut the tank. Generally, if you're cutting your washing machine at home, the only time you'll have to do it is a pain. However, repairmen who perform repairs on a daily basis are forced to look for a more convenient cutting method.

An alternative to a standard hacksaw for metal is a Gross hacksaw for wood, equipped with fine teeth.

Thanks to its hardened teeth, it cuts plastic perfectly. The cut is very smooth, and the tank surface doesn't bend or break under its impact. Compared to a standard hacksaw, the Gross cuts the cutting time by approximately 1-1.5 hours.

However, this method of dividing the tank is also not the fastest. The best way to cut a tank is to use a jigsaw to divide it. To quickly cut a drum you will need:

- standard electric jigsaw;

- two washers and a bearing (for a 4 bolt);

- hacksaw blade.

A jigsaw blade is very wide. Therefore, it's recommended to use a thinner blade from a regular hand jigsaw. Take a look at the tip of a jigsaw blade. This configuration allows it to fit easily into the jigsaw opening. A jigsaw blade should be shaped similarly.

Now that one end of the thin hacksaw blade is shaped to fit into the jigsaw, it's time to secure the assembly using washers, a bearing, and a bolt. The washers are placed on the sides, the bearing is placed in the middle, and everything is secured with a bolt. The design looks quite simple.

The hacksaw blade is inserted into the jigsaw and clamped.

Once the structure is securely fastened, you can begin cutting the drum into two halves. You can also cut the drum using a hand jigsaw, but the process will take much longer. It's better to spend a few minutes adapting a standard blade to a jigsaw.

Sawing time and result

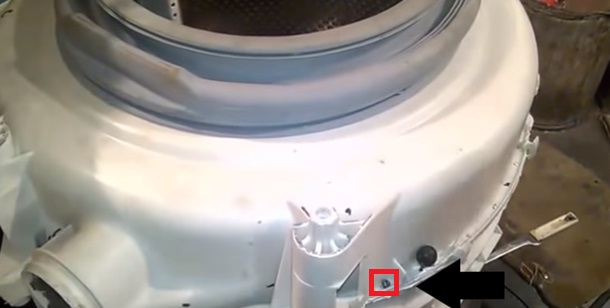

A modified jigsaw will help you spend minimal time on cutting. Before moving on to the main work, it's necessary to cut off all the "ears" from the surface of the tank—that is, any protrusions on the weld seam that would interfere with cutting. Next, place the blade on the seam, and start the jigsaw.

It is important to monitor the position of the saw; it should run almost parallel to the tank to avoid damaging the elements.

Also, if you're new to this method, it's best to go through difficult areas of the tank (such as the area shown in the picture above) by hand. This will help ensure the tank is cut as cleanly as possible.

A skilled craftsman can cut a tank with a jigsaw in just 45-50 minutes. While it may take you longer to cut a tank for the first time, remember that the job will go faster with each new attempt. The jigsaw cutting method is very effective and does not require much effort from the sawer.

Connecting the halves of the tank

Once the tub is cut, you can move on to replacing the bearings, installing a new seal, repairing the universal joint, and so on. Once the work is complete, there's one more important task: reassembling the monolithic tub of the Indesit washing machine. To reassemble the tub, you'll need to prepare:

- silicone moisture-resistant sealant;

- two fasteners for securing the halves (for example, you can use a regular awl);

- screws with nuts.

The algorithm of actions will be as follows:

- degrease the seam on both halves of the tank;

- Apply a moisture-resistant sealant to the joint.

The surface must be thoroughly lubricated, without missing a single spot. To bond the tank, you need to choose a sealant that can withstand temperature fluctuations, pressure, vibration, and exposure to water.

- Connect the two parts of the tank. Place the lid on the base, pressing it lightly;

- To prevent the halves from slipping during further work, secure them. The clamps (in our case, awls) are installed in two places on the sides of the tank, in holes in the weld seam;

- Take the screws and insert them into the holes around the perimeter of the seam. Tighten them. This way, the two halves of the tank will be securely fastened together.

Let the tank sit for a few minutes until the sealant has completely dried. Next, attach the drain hose to the tank. Seal the hole for it with sealant, then insert the hose. Next, attach the counterweight, shock absorbers, and other components to the tank. These steps are not relevant to this topic, so we won't dwell on them.

As you can see, disassembling and re-welding the Indesit washing machine tub can be done in just a couple of hours. The job will go especially quickly if you choose a non-standard cutting method. Cutting the tub with a jigsaw will save you not only time but also effort. Using a hacksaw requires applying pressure to the seam and constant manual work, but in our case, simply hold the jigsaw firmly, guide the blade, and ensure it doesn't cut too deep.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment