Disassembling the washing machine tank

The need to disassemble a washing machine's drum may arise due to various problems, such as wear on the bearing assembly. Is it possible to do the job yourself, without calling a professional?

The need to disassemble a washing machine's drum may arise due to various problems, such as wear on the bearing assembly. Is it possible to do the job yourself, without calling a professional?

Washing machines can be equipped with either a dismountable or a non-dismountable tank. In the former case, the two halves of the tank are held together with screws, and to separate them, simply remove the fasteners. The latter situation is much more complex, so below we'll discuss how to separate a monolithic tank.

The first difficulty is removing the tank

To disassemble a washing machine's drum, you first need to remove it from the housing. This is also a fairly complex and labor-intensive task. The container extraction algorithm will be similar for all washing machine models; the differences will be in front-loading and vertical-loading machines.

For front-facing models, when removing the tank, you will need to remove the front panel; for vertical-facing models, you will need to remove the side wall of the housing.

When disassembling the washing machine and the drum itself, you'll need some tools. You'll need to have the following on hand:

- a pair of screwdrivers (Phillips and slotted);

- screwdriver;

- socket heads of different diameters;

- hacksaw for metal;

- pliers;

- a punch and a small hammer;

- marker or simple pencil;

- ratchet wrench;

- drill size 3-5 mm.

It's also a good idea to have a mobile phone with a camera handy. While working, it's recommended to take photos of the connection diagrams and the original component placement. This will help avoid mistakes during reassembly.

Before disassembling your washing machine, be sure to disconnect the power. Unplug the power cord and move the washing machine away from the wall and furniture to ensure easy access to all sides of the machine. Next:

- close the shut-off valve supplying water to the machine;

- drain the remaining liquid from the system through a waste filter;

- detach the drain and filler hoses from the body;

- Unscrew the screws holding the top panel of the case;

- remove the top of the washing machine and set it aside;

- remove the detergent drawer from the machine;

- Remove the bolts securing the washing machine's control panel. The dashboard doesn't need to be completely removed; simply place it on top of the machine.

- open the hatch door, feel the outer clamp holding the drum cuff;

- loosen the clamp latch and remove it from the washing machine;

- tuck the sealing cuff inside the drum;

- unscrew the screws holding the hatch locking device;

- reset the UBL contacts and remove the blocker;

- remove the lower false panel;

- remove the remaining bolts securing the front wall of the case;

- move the front panel of the washing machine aside;

- remove the rear panel of the machine by unscrewing the bolts around the perimeter of the panel;

- remove the heating element by loosening its nut and disconnecting the wiring from the heater;

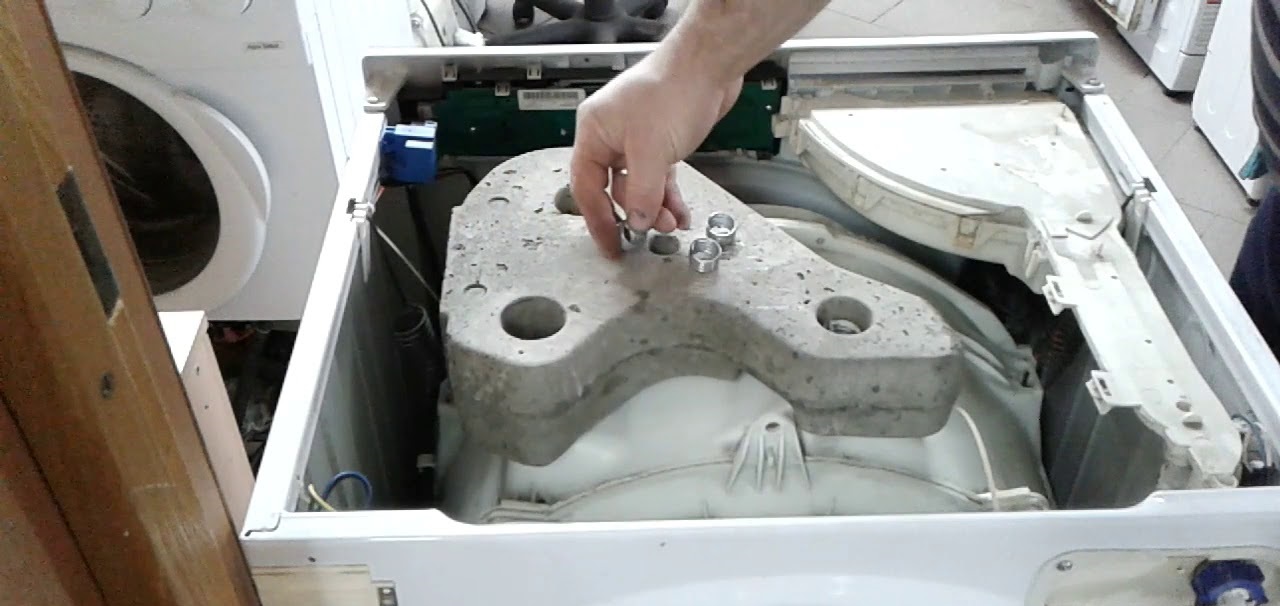

- remove the counterweights adjacent to the tank;

- remove the drive belt from the drum pulley and motor;

- Disconnect the power supply wiring from the engine.

After this, there will be virtually nothing to interfere with removing the tank. All that remains is to loosen the shock absorbers, so unscrew the spring fasteners. Now you can remove the tank from the machine. After removing the non-detachable structure, place it on a hard, level surface for further work.

With collapsible tanks, this won't be a problem. To split the tank in half, simply use the fasteners around the circumference. Non-collapsible, monolithic structures are a different matter.

We remove the drum from the non-separable tank

It's not profitable for manufacturers to equip washing machines with removable tanks. For example, if the bearings are damaged, the user can easily replace them. And when the unit is non-detachable, many find it easier to buy a complete tank rather than cut up the factory-installed one. Companies are counting on profiting from selling components.

However, technicians have figured out a way to access the inside of the non-detachable drum. Experience shows that after this intervention, washing machines continue to function smoothly for a long time, provided, of course, everything is done correctly and the two halves of the drum are securely fastened together. The procedure is as follows:

- draw a cutting line on the tank;

- drill holes around the circumference at a distance of 5-7 cm from each other;

- Carefully cut the tank with a hacksaw along the marked line.

This will give you access to the inside of the tank. Then you can begin repairs—changing bearings, seals, etc. It's important to understand that this is quite labor-intensive and delicate work, so assess your capabilities beforehand.

Detailed description of the work stages

Once the container is placed on a flat surface, you can begin disassembling it. Wipe the plastic with a clean cloth. A very important step is marking the cutting line along the perimeter of the tank’s weld seam. It is recommended to drill holes 5-7 cm apart. A drill bit with a diameter of 3-5 mm is used for this purpose.

The cut line should be easily traced through the holes made.

Once the holes are made, grab a hacksaw. Don't rush—cut the tank carefully, avoiding any sudden movements. This will cause the integral structure to split into halves. The rear "half tank" will contain the drum, along with the bearings and seal.

If you need to remove the drum, you'll need to remove the pulley. The "wheel" is secured with glue by the manufacturer, and removing the bolt holding it in place will be difficult. Therefore, place a bit on the screw and hit it several times with a hammer.

When replacing bearings, you'll need to remove the damaged rings from the drum. A drift will be required for this. After knocking out the parts, clean the bearing surface of any debris or dirt.

Next, install the new bearings and seal. It's important to generously coat the components with special grease. The silicone will protect the unit from moisture, thereby extending the life of the components.

Once the damage is repaired, you can begin reassembling the tank. To do this, thoroughly clean the cut areas. Next, apply a waterproof silicone sealant around the entire perimeter and overlap the halves.

Screws are inserted into the holes drilled at the beginning of the installation to secure the two parts of the tank together. If the tank is properly secured, it will not leak. Once the assembly is complete, you can begin reassembling the washing machine.

As you can see, accessing the inside of a non-separable tank is possible. Yes, it's a fairly labor-intensive process, but it will save you a considerable amount of money that would otherwise have been spent on a new unit. The work can easily be done at home, without the help of a professional.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment