Disassembling the Candy washing machine drum

The washing machine's plastic drum contains hidden components that ensure the drum rotates smoothly. When the bearing assembly wears out, the machine begins to make noise, grind, and vibrate heavily during the spin cycle. A slight play is also observed.

The washing machine's plastic drum contains hidden components that ensure the drum rotates smoothly. When the bearing assembly wears out, the machine begins to make noise, grind, and vibrate heavily during the spin cycle. A slight play is also observed.

Unfortunately, bearing wear is a problem that almost all users encounter after several years of washing machine use. We'll explain how to disassemble the drum of a Candy washing machine and what challenges you might encounter along the way. We'll also list the tools you'll need for the job.

Is this type of repair available?

The bearing assembly allows the washing machine drum to rotate smoothly and gently. However, the bearings are constantly subject to increased stress and are therefore subject to natural wear. When the bearings wear out, the washing machine begins to make noise and knock during operation, especially during the spin cycle.

The bearings are located on the drum cover. To access them, you need to not only remove the main drum from the machine body, but also split it in half. The problem is that most SMAs Candy equipped with non-separable tanks.

Therefore, removing the tank from the housing isn't the most difficult task. Disassembling a molded plastic container is much more challenging. In such cases, repair shops and service centers offer to replace the entire unit, but the cost of such a repair can be 60-70% of the price of a new washing machine.

In fact, it is possible to split a non-separable tank in half and then reassemble the reservoir without losing its seal, even at home.

Therefore, if you don't want to spend money on expensive repairs, you can try cutting the tank in half with a hacksaw, replacing the bearings, and then gluing the plastic tank back together. This can save you a lot of money, but keep in mind that this type of work will require a lot of time, patience, and skill.

What tools do you need to get?

It's important to prepare for the upcoming renovation. To avoid getting distracted by searching for tools, it's best to gather everything you need right away. So, you should have the following on hand:

- a hacksaw or grinder;

- pliers;

- marker;

- open-end wrenches of different sizes (from 8 to 18 mm);

- Phillips and slotted screwdrivers;

- set of heads with ratchets;

- hammer;

- punch;

- awl;

- drill.

It's also best to buy spare parts right away. When selecting components, consider the model and serial number of your Candy washing machine. Most automatic machines from this brand have two bearings and one seal.

Where are we going to do the repairs?

It's important to ensure comfortable working conditions. Since the washing machine will require almost complete disassembly, there should be plenty of free space. Ideally, transport the washing machine to a workshop or garage. If this isn't possible, move it to a room with 2-3 square meters of free space.

Before moving the washing machine:

- de-energize the device by unplugging the power cord from the socket;

- Disconnect the drain and inlet hoses from the washing machine.

Next, prepare the work area by covering it with a cloth or newspaper. Then, move the machine into this area. Remove the detergent drawer from the machine and set the tray aside. The next step is to drain the remaining water from the washing machine's drum. To do this:

- Place a low container under the machine where the waste bin is located;

- start to unscrew the drain filter little by little;

- wait until the water drains into the container;

- Rinse the drain filter in warm water.

It's also worth thinking ahead about where you'll store small parts: screws, latches, and clamps. It's best to set aside a space for detachable parts right away—you can place the powder drawer and dust filter there. Then, begin disassembling the washing machine.

We are trying to get to the machine's tank

The next, rather lengthy stage is disassembling the machine. To remove the tank from the housing, you need to disconnect all the wires, pipes, and parts from it. The algorithm will be as follows:

- remove the washing machine housing cover - to do this, unscrew the bolts holding the “top”, then pull it towards you and up;

- remove the technical hatch (the panel is located on the rear wall of the case);

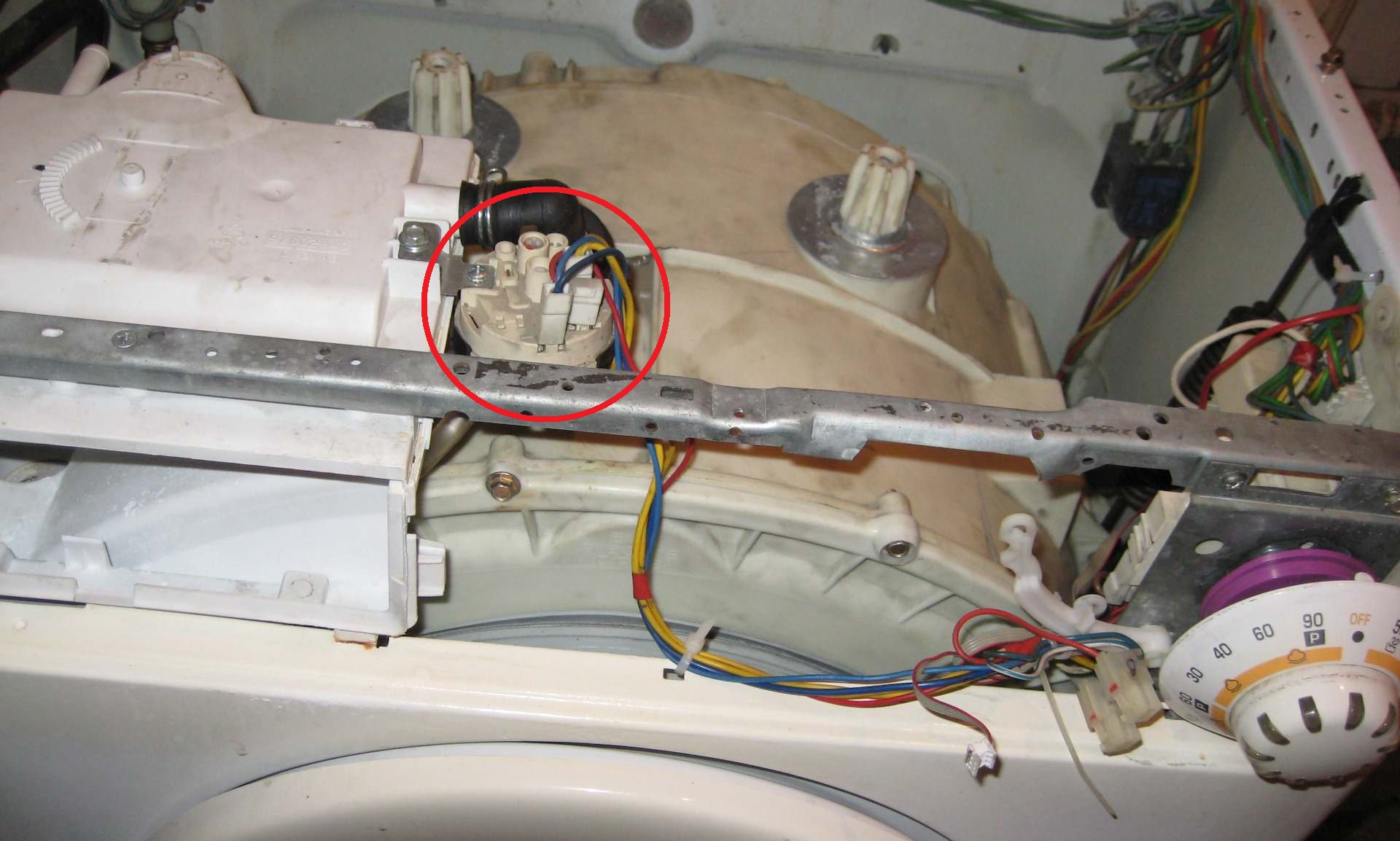

- unscrew the inlet valve fastening and pull the element out;

- disconnect the pipe and remove the powder receptacle niche;

- unscrew the bolts holding the instrument panel;

- reset the contacts connected to the instrument panel (after taking a photo of the connection diagram),

- Having dealt with the latches, detach the instrument panel from the housing and put it aside;

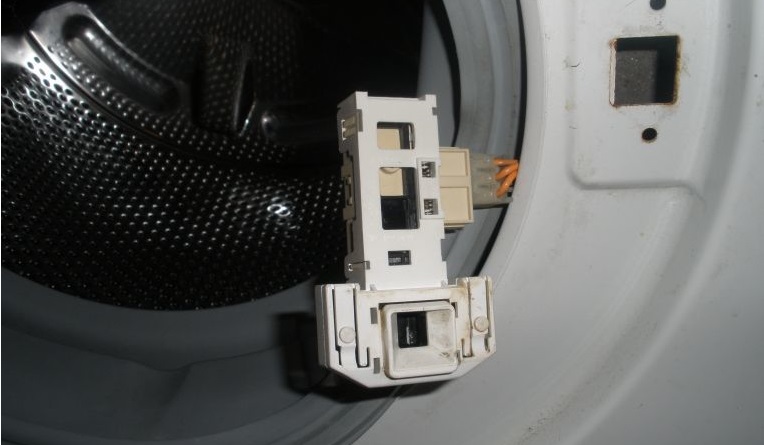

- remove the outer compression clamp of the drum cuff by using a screwdriver to hook its fastening;

- tuck the rubber cuff inside the machine;

- disconnect the UBL contacts;

- remove the front and back panels of the case, having first removed the fixing screws;

- Pull the drive belt off the pulley.

At this stage, you need to carefully inspect the rear surface of the tank. If rusty streaks are coming out of the center, the bearings and seal definitely need replacing. Let's continue disassembling:

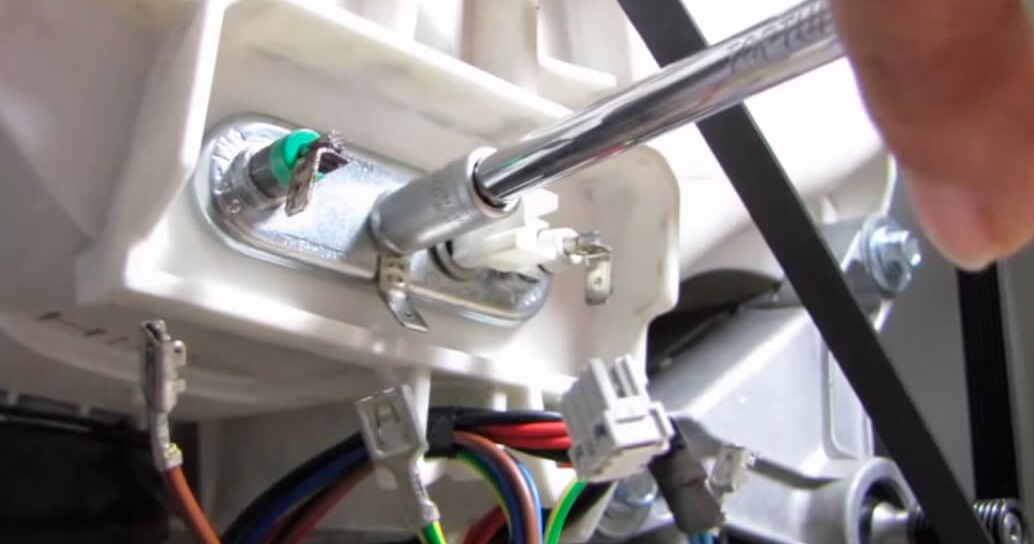

- find the heating element, disconnect all contacts from it;

- unscrew the heater nut;

- remove the heating element from the groove;

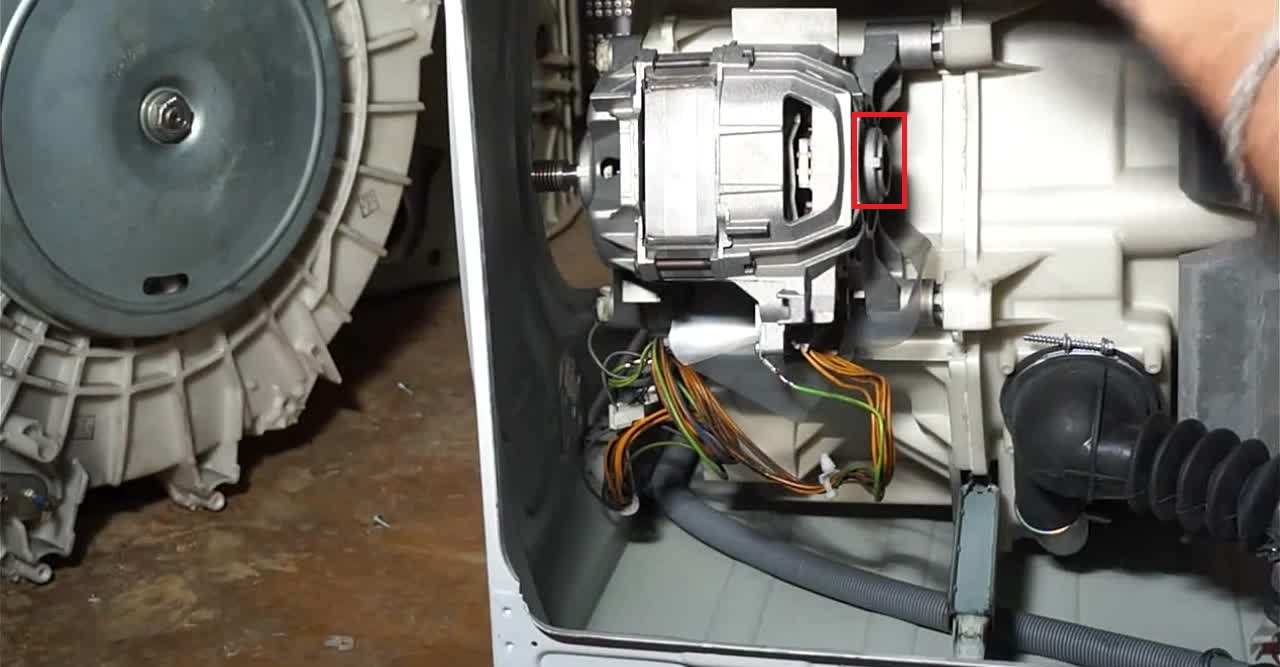

- remove the connectors and wiring from the engine;

- Remove the bolts holding the motor and remove the motor from the housing.

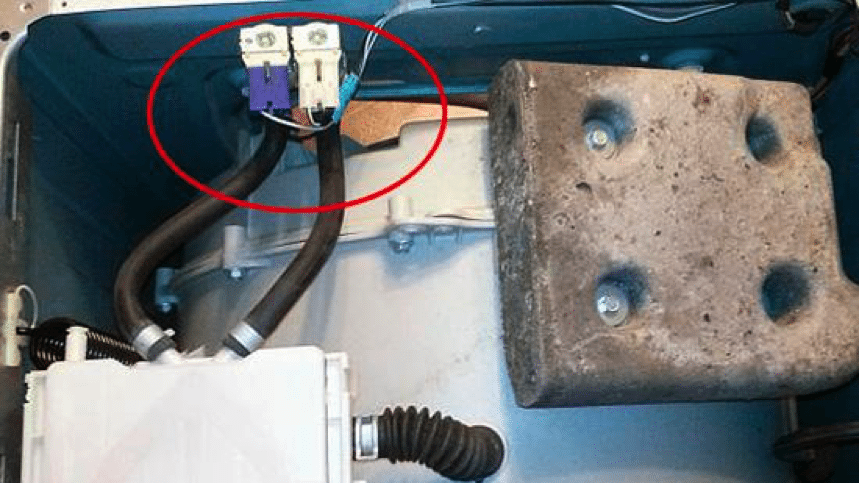

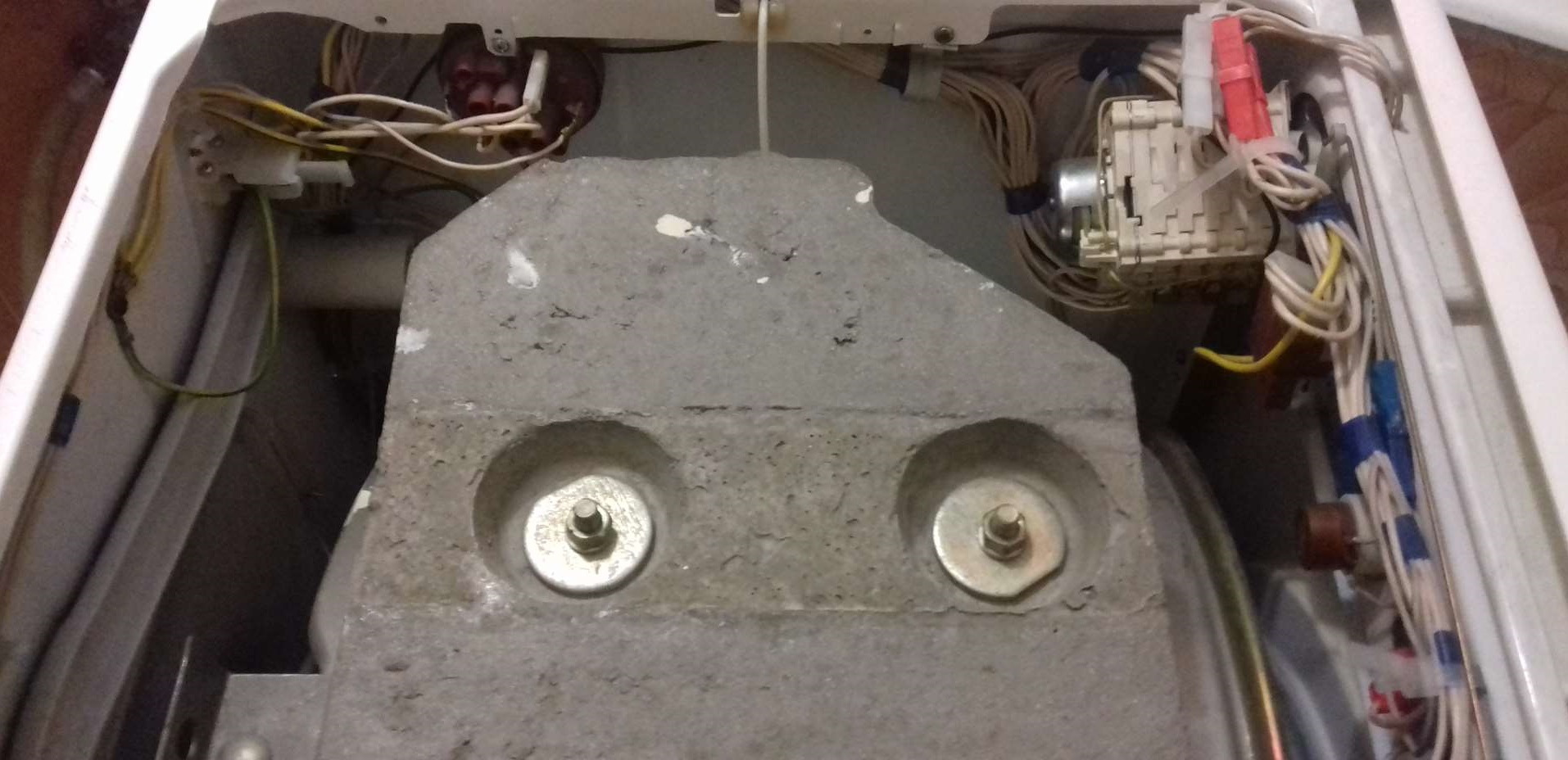

Now we'll have to work on the top of the washing machine. Next up is the counterweight. It's designed to absorb the centrifugal force generated during operation. The counterweight resembles a large, flat stone.

The counterweight is removed using a socket wrench. The bolts securing the concrete block must be removed. The counterweight can be set aside.

The counterweight is quite heavy, so be careful when removing it.

The water level sensor also needs to be removed. Disconnect the wiring from the pressure switch, then unhook the element from its mounting. Be careful not to damage the plastic retainer.

After this, carefully lay the washing machine on its right side. Most Candy models don't have a bottom. If there is a tray, remove the panel.

Next up is the pump and drain hose. The hose is very easy to disconnect—just loosen the clamp. The pump also comes out of the housing after removing the retaining bolts.

Finally, you need to disconnect the shock absorbers from the drum. Unscrew the fasteners that hold the struts in place. Remove the shock absorbers. After this, you can stand the washing machine upright again.

How to properly cut the tank of a Candy washing machine?

The plastic tank is cut outside the machine's housing, so you'll first need to remove the unit from the machine. This is difficult to do alone; it's best to use a partner. Therefore, enlist the help of a helper.

Next, lay the tank on the floor. Make sure the structure is truly non-detachable. This way, the halves of the tank will be welded together, and there won't be any bolts or nuts along the seam.

The plastic tank is cut with a hacksaw or a grinder.

The cut must be made exactly along the weld seam. Before cutting, stand the tank upright. Also, drill 5-6 holes on the central rib, spaced 6-7 cm apart. Screws will be inserted into these holes during reassembly to provide additional structural stability.

After sawing, set the top half of the tank aside. The drum and bearings are located at the bottom. This is where we'll be working from now on.

We divide the tank into halves and remove the bearings.

Now you need to separate the drum from the bottom of the tank. First, unscrew the nut securing the pulley. If the fastener is stuck to the shaft, treat it with WD-40 and wait 15-20 minutes. Then try again.

Having dealt with the nut:

- disconnect the pulley;

- screw any bolt into the thread (just not one removed from the machine, otherwise it may get damaged);

- Place the rubber part of a mallet or a small wooden block on the bolt;

- tap the block with a hammer until the drum pops out of the tank half;

- If the parts do not separate, treat the area around the bolt with WD-40 aerosol lubricant, wait 15 minutes and tap the structure again with a hammer.

The bearings are located on the drum shaft. They can be removed using a special puller. If a tool is not available, they can be pressed out using a hammer and punch.

Rings are always exchanged in pairs. The oil seal is changed at the same time as the bearings. The components also need to be treated with a special lubricant to extend their lifespan. Spare parts are purchased for a specific Candy washing machine model. Pressing in new components is also done with a hammer and punch.

Now you can begin assembling the tank. Clean the edges of the halves and seal them with water-resistant silicone sealant. Next, place the halves on top of each other. Then screw the bolts into the previously drilled holes and secure them with nuts.

Reassembly is performed in reverse order. First, install the tank, connect the shock absorbers, counterweights, and hoses. Replace the heating element, motor, seal, and drain pump. Reconnect the removed wires and contacts. Secure all housing walls and the control panel. Insert the powder receptacle into the dispenser.

After assembling your Candy washing machine, be sure to run a test cycle. Observe how your "home helper" performs. There should be no leaks, unusual noise, or strong vibrations. If everything is in order, the repair is complete.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment