Disassembling the washing machine pressure switch

Every automatic washing machine is equipped with a water level sensor—a relay monitors the tank's fill level. If a malfunction occurs, it may be necessary to disassemble the washing machine's pressure switch. We'll explain the components of the device, how to properly open its housing, and, if necessary, how to adjust the element.

Every automatic washing machine is equipped with a water level sensor—a relay monitors the tank's fill level. If a malfunction occurs, it may be necessary to disassemble the washing machine's pressure switch. We'll explain the components of the device, how to properly open its housing, and, if necessary, how to adjust the element.

We open the relay housing

To check for debris in the pressure switch or short-circuiting, you may need to disassemble the water level sensor. You can open the device's housing yourself. The procedure is as follows:

- de-energize the machine;

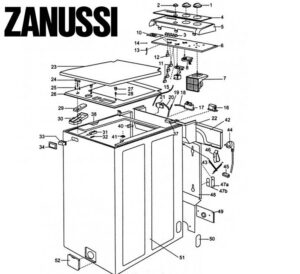

- remove the top cover of the case;

- find the pressure switch;

- Unscrew the screw holding the sensor, disconnect the pipe and connector;

- remove the element from the housing.

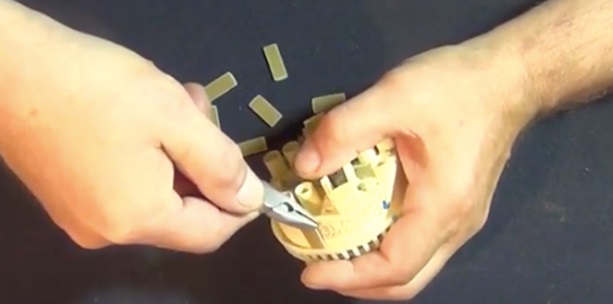

Before disassembling the pressure switch housing, be sure to mark it with a marker. This is necessary to ensure the two halves of the plastic "shell" are perfectly aligned later. To disassemble the pressure switch as carefully as possible, you will need:

- unwanted plastic card;

- scissors;

- pliers,

- small thin screwdriver.

The algorithm of actions will be as follows:

- Cut the plastic card into 1x2 cm pieces. You will need about 8 of these "pieces" in total;

- Insert the plastic pieces one by one between the two halves of the pressure switch using pliers;

- Use a screwdriver to pry up the top half of the "shell".

After prying the housing two or three times, you'll see that the shell easily splits in half. This allows quick access to the pressure switch's interior. Remove the membrane and inspect the sensor contacts.

Testing and configuring the sensor

Before attempting any repairs to your "home helper," find your receipts and check if the washing machine is still under warranty. If it's still under warranty and you're eligible for a free diagnostic, it's best to contact a service center. It is important to remember that if you open the machine case yourself, you cannot count on warranty service in the future.

If the warranty card is no longer valid, you can begin diagnostics. First, remove the sensor from its housing. The procedure is as follows:

- de-energize the washing machine by pulling the power cord out of the socket;

- turn off the tap that supplies water;

- Unscrew the two bolts securing the top panel of the machine;

- remove the "cover" of the unit;

- find the pressure switch - it has the shape of a washer;

- unscrew the bolt securing the relay in the housing, remove the connector;

- loosen the clamp and remove the sensor from the machine.

Before adjusting the device, check to see if it's working properly. For diagnostics, you'll need a rubber tube of the same diameter as the pressure switch. After removing the level sensor, attach the prepared tube to its inlet. Then blow into it; a working pressure switch will emit 1-3 characteristic clicks. If the device remains silent, the contacts are not engaging and the relay is faulty.

Afterwards, inspect the level sensor. Make sure it's not deformed and there are no signs of burning on the surface. Also, check the hose for a blockage; sometimes the cavity becomes clogged with dust. If the tube is clogged, blow it out or rinse it with warm water.

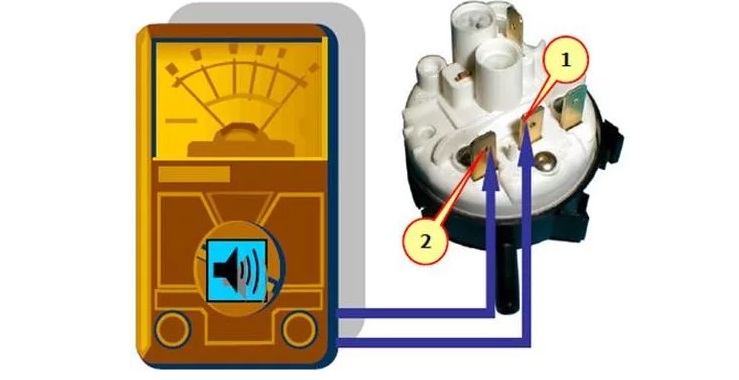

For a more complete check of the water level sensor, you will need a multimeter.

Hardware diagnostics of a pressure switch are more accurate. To test the device, set the device to resistance measurement mode and attach the multimeter probes to the pressure switch terminals. Pressure must be created in the tube for the contacts to activate.

If the values on the multimeter display remain unchanged when the relay contacts are activated, the pressure switch will need to be replaced. If the numbers on the screen change, the sensor is probably faulty. In this case, simply adjusting the existing device may be sufficient.

The level sensor is adjusted manually. Adjustment is useful when too little or too much water is being added to the drum during a wash cycle. The amount of liquid the washing machine draws can be increased or decreased by adjusting the pressure switch's response force.

First, disconnect the power from the machine. Next, remove the top panel, locate the pressure switch, and disconnect the connector. The relay has three adjustment screws, one of which needs to be adjusted. The bolt used for adjustment is usually located in the central part.

It is essential to adjust the pressure switch of the washing machine when the tank is empty.

To tighten the screw, you'll need a Phillips-head screwdriver or a special key. The process is carried out in stages, assessing the interim results of the pressure switch adjustment. For example, turn the screw half a turn, then reassemble the machine body and begin a test "empty" wash. If the desired effect isn't achieved, turn the screw again.

To adjust the pressure switch, you need a basic understanding of the internal workings of a washing machine. If you don't have even the slightest idea how the level sensor works, it's best to call a professional to do the job. Otherwise, you could cause even more damage to your "home helper."

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment