Disassembling a Vestel washing machine

Disassembling a Vestel washing machine for the first time, whether for repair or for parts, can be quite challenging. You'll have to remove almost all key components, including the front panel and the drum. The drum itself must be separated and removed. This can be challenging without clear instructions, especially when it comes to diagnostics and repairs. To avoid damaging the machine or removing unnecessary parts, follow the instructions strictly.

Disassembling a Vestel washing machine for the first time, whether for repair or for parts, can be quite challenging. You'll have to remove almost all key components, including the front panel and the drum. The drum itself must be separated and removed. This can be challenging without clear instructions, especially when it comes to diagnostics and repairs. To avoid damaging the machine or removing unnecessary parts, follow the instructions strictly.

Preliminary actions

It's not recommended to immediately begin disassembling a Vestel washing machine. First, prepare for the work ahead. First, find a space for the repair. Ideally, this should be a workshop or garage, not a small bathroom. If there is no special room, then you need to move the machine away from the walls as much as possible, ensuring free access to the rear, front and side panels of the case. The next step is preparing the washing machine itself. You will need:

- disconnect the machine from all communications (water supply, sewerage and electricity);

- Empty the tank by draining the remaining water (through the waste filter or emergency drain hose).

To ensure a smooth and hassle-free disassembly of your washing machine, it's important to plan ahead for the storage of the parts to be removed. Large components should be placed next to each other in the order they were removed from the housing. Fasteners, clamps, and other small parts should be sorted into containers or placed on the inverted top cover of the housing.

It is recommended to record the dismantling process with a photo or video camera to simplify reassembly and connection.

Experienced mechanics recommend preparing a piece of thick wire bent into an "S" shape. It should be hooked to the right side of the case for future use as a hook under the dashboard. This life hack eliminates the need to disconnect the wiring from the board, which is very difficult to reconnect for beginners. During the preparation phase, gather the following tools:

- flat and Phillips screwdriver;

- pliers;

- hacksaw for metal (if you plan to dismantle the drum);

- set of heads;

- set of open-end wrenches;

- hammer;

- rubber mallet;

- drift or car puller.

We also prepare some WD-40 lubricant, which will help loosen stuck and rusted parts. Place a rag nearby and cover the area around the washer with plastic. That's it! Now we can begin disassembling the Vestel.

Removing the outer body elements

Disassembly begins with removing the external components. This includes the powder receptacle, hatch, top cover, and front and rear panels. Here's how to proceed:

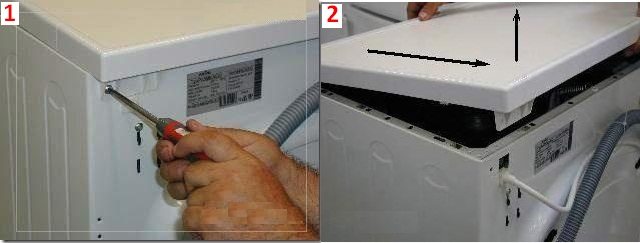

- we find two bolts on the lugs at the back that hold the top cover of the case;

- unscrew the screws;

- we push the cover back and, lifting it, disconnect it from the body;

- remove the powder receptacle (pull it all the way and press on the “tongue” in the center of the dispenser);

- we unscrew the screws located in the tray niche;

- loosen the screws on the hatch hinges and remove the door;

- We use a screwdriver to pry up the outer clamp on the cuff, loosen it and put it aside;

- we tuck the cuff inside the drum;

It is not recommended to remove the entire cuff from the drum - it is very difficult to pull it back!

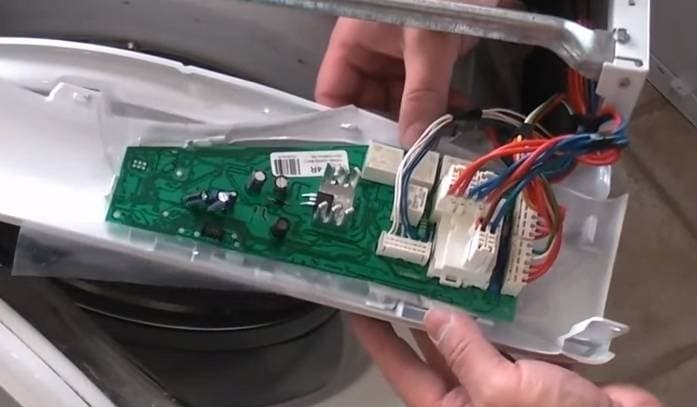

- We detach the instrument panel (unscrew the screws around the perimeter and press the plastic latches) and hang it on an S-shaped wire hook.

Next in line is the front panel of the case. To remove it, you need to unscrew all the fixing bolts: under the dashboard, around the debris filter and near the hatch lock. Next, pry the side panel up with a screwdriver, press the latches, and set the end aside. The back panel is easier to remove. Simply unscrew a few screws holding it in place, and then pull it away from the case.

After removing all external components, you'll have easy access to the machine's internal structure. But disassembling the Vestel doesn't end there—you'll need to remove the instruments and sensors from the tank, and then disassemble the tank itself. We'll discuss the sequence of these steps below.

We remove the elements around the tank

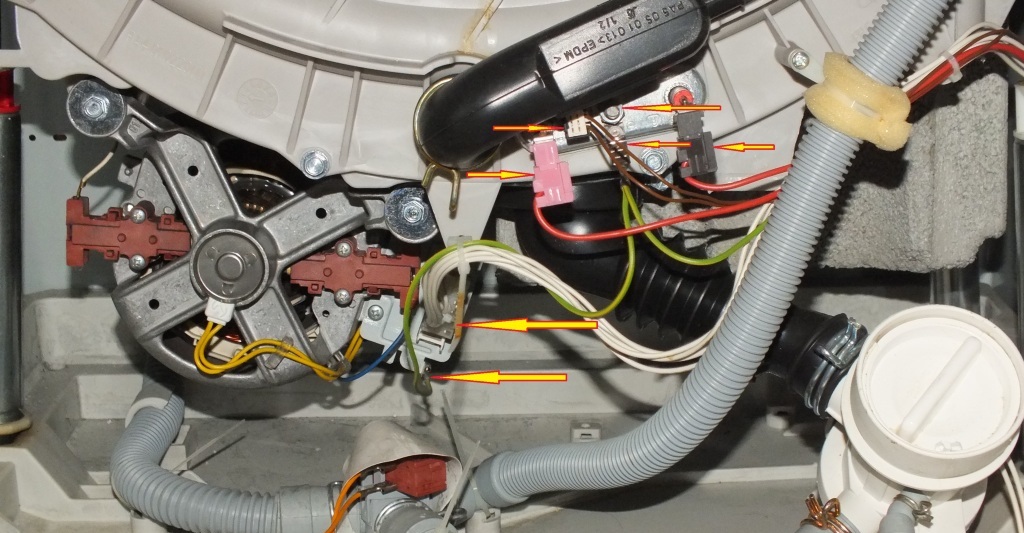

Before removing the Vestel washing machine from its housing, remove any wires or other connected components. Disconnect the counterweights, drive belt, electric motor, heater, dampers, pump, and other vital system components. Disassembly proceeds in the following order:

- We go to the back wall of Vestel and tighten the drive belt by turning the pulley;

- we release the electric motor from the connected wires;

- loosen the motor fixing bolts;

- we push the engine inward and, after rocking it, we take it out of the housing;

- remove the heater (disconnect the terminals from the heating element and the thermistor, unscrew the nut in the center, push the device deeper and remove it from the grooves).

Now let's turn our attention to the upper part of the housing. First, unscrew the bolts securing the counterweights and remove the concrete blocks one by one. Next, disconnect the wiring from the inlet valve and the hoses leading to the detergent drawer. Be sure to also remove the pressure switch: both the hose and the "box" itself.

Before removing the tank with the drum, it is necessary to free it from connected parts, hoses and wires.

The drainage system is disassembled through the bottom. More precisely, the pump is removed from the volute. To do this, we disconnect the wiring, loosen the fasteners, turn the pump housing clockwise, and, pressing the unit in, remove it from the housing. Finally, we tackle the shock absorption. First, unscrew the dampers and remove the posts from the housing, and then loosen the upper springs. That's it! Now the washing tank is held in place only by the hooks and grooves provided. You need to lift the tank and pull it toward you. The tank is light, but awkward to handle—it's best to have a helper.

Removing and cutting the tank in half

The removed drum is placed on a flat, dry surface and inspected. As a rule, Vestel washing machines are equipped with solid plastic tanks, welded using a special technology. You can't just cut it in half—you have to saw it, then screw it together and seal it with sealant. Separable tanks are easier: just unscrew the bolts around the perimeter and release the latches. Damaging the tank is very easy, so be extremely careful when disassembling it:

- loosen the screw located in the center of the drum pulley;

- we cut the tank in half (we saw the container with a hacksaw or unscrew the bolts);

- we put the “empty” half aside and turn the other one over with the shaft facing up;

- we inspect the crosspiece and, having fixed one of the blades with a block, unscrew it;

- we pry up the seal with a screwdriver and remove it;

- Using a punch, hammer and mallet, we knock out the old bearings.

Before dismantling, seized parts and fasteners are treated with WD-40 lubricant.

When disassembling a Vestel washing machine, it's recommended not to neglect cleaning. Immediately rinse all dirty areas, especially the debris filter seat, the pump housing, and the shaft freed from its bearings. If the scale buildup is severe, use WD-40: apply and let sit for 15-20 minutes. Once the bearings are removed, disassembly is complete. Now you can begin replacement or diagnostics, depending on your initial purpose. Reassembling the Vestel is the reverse process, but with some caveats, which are discussed in a separate article.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

You need to show how to disassemble and not break!