Adjusting the pressure switch on an Indesit washing machine

If your Indesit washing machine is filling with too little water or, conversely, is threatening to overflow, you should check the pressure switch. It's likely the level sensor is faulty, clogged, or its factory settings have been reset due to vibrations or power surges. In any case, it needs to be inspected, repaired, and replaced. To successfully adjust the pressure switch on your Indesit washing machine, follow these instructions.

If your Indesit washing machine is filling with too little water or, conversely, is threatening to overflow, you should check the pressure switch. It's likely the level sensor is faulty, clogged, or its factory settings have been reset due to vibrations or power surges. In any case, it needs to be inspected, repaired, and replaced. To successfully adjust the pressure switch on your Indesit washing machine, follow these instructions.

Finding the part

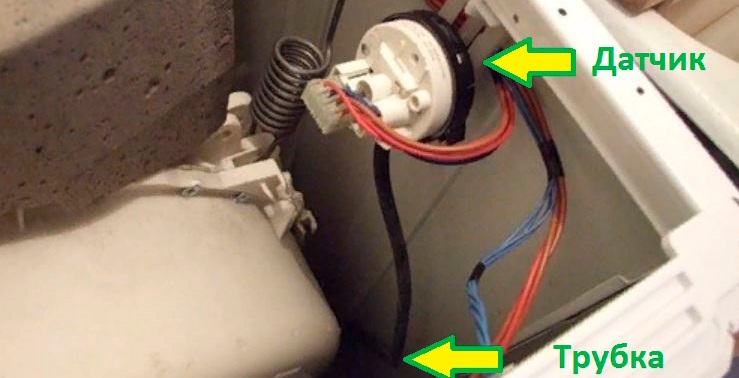

The pressure switch consists of two parts: a round plastic washer and a long rubber tube. The first is located just under the top cover and is attached to the left side of the washing machine, while the second is attached to the washer at one end and to the tank nipple at the other. This measures the pressure in the tank and records the water level. To access the sensor, you need to remove the top cover of the machine. To do this, follow these steps.

- Using a Phillips screwdriver, unscrew the two bolts holding the top cover from the back wall of the Indesit.

- Lifting the cover from the back side, push towards yourself until you hear 2-3 clicks from the latches engaging.

It is not recommended to pull the lid too hard, as the plastic latches can easily break.

- If the lid does not move, you can increase the pressure and change the side of the pressure on the panel.

As soon as the cover moves from its place, we remove it and examine the internal parts of the machine. Typically, the level sensor washer has a white, black or blue body color. The pressure switch and the tube that goes deep into the machine “give it out”.

How do you know if the pressure switch is broken?

Before attempting to repair or adjust the water level sensor, you should first verify that it's faulty. This can be easily determined by paying close attention to the washing machine's behavior. For example, an unusual humming sound when drawing water, a cycle that doesn't start, or a continuous drain should be cause for concern.

The display will clearly indicate problems with the pressure switch. If the "F05" code lights up on the machine, there's a 70% chance that the level sensor is malfunctioning. The risk increases to 85% when the user notices that there's either too little or too much water in the drum.

Ignoring a broken pressure switch is strongly discouraged. Operating the machine with a faulty sensor can significantly worsen the problem. If there's not enough water in the tank, the heating element will burn out, and if there's too much water, the pump will be damaged because it can't handle the volume. Even worse, if the triac on the control board fails, the repair cost will double or triple.

What do we check first?

Once you've confirmed the pressure switch is faulty, you need to begin diagnostics. First, check the water intake system: the hose, the fitting, and the device's "chamber." If there are no cracks, abrasions, or chips, the parts are fine. If a deposit from washing powder is detected, the sensor is disassembled and all components are washed. When damage is visible on a tube or washer, repair will not help – only a complete replacement.

The second step is to check the connection to the electrical system. It's quite possible that a wire is frayed or bent, a contact has come loose, or a terminal has become loose. It's also important to inspect the sensor's contact group, as any buildup and dirt inside can cause significant problems. Finally, the pressure switch needs to be tested. Here's how to proceed.

- We find a tube that matches the diameter of the pressure switch fitting.

- We insert one end of the found tube into the sensor hose.

- We blow gently towards the other end.

- Listen carefully: if you hear 1-3 clicks, then the sensor is OK.

If the pressure switch is intact and clicks correctly, but the machine still won't wash, you'll need to adjust the sensor. There's no need to call a repairman—almost any washing machine owner can handle this adjustment. Instructions and recommendations are provided below.

Setting up the part

Adjusting the pressure switch is not a difficult task, but it is painstaking and time-consuming. The main thing is to act with extreme caution, do not rush and do not deviate from the instructions.It's also important to thoroughly prepare for the setup, which requires completing a number of steps.

- Disconnect the machine from communications, electricity and water supply.

Before disconnecting the pressure switch wiring, it is recommended to record the location of the conductors with a camera so as not to make a mistake with the phase when reconnecting.

- Loosen the bolts and release the wiring connected to the sensor.

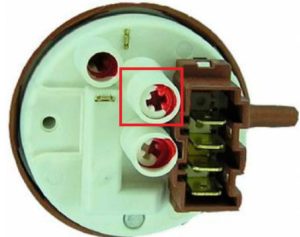

- Find the screws near the terminals that are used to attract and loosen the device contacts.

- Remove the sealant from the screws.

The screws mentioned earlier are the ones we'll be working on. The main task is to detect the moment when the contacts close and open. This will create optimal operating parameters, and the pressure switch will trigger at the right moment and accurately measure the water level in the tank. Professional repairmen use a special device for this purpose, but ordinary users typically don't have such a mechanism. However, the well-known "trial and error" method can be used. Here's how to proceed.

- Carefully turn the first screw half a turn in any direction.

- We return the pressure switch to its place and start the washing machine on the fastest mode.

- We evaluate the quality of the kit. If the water level was low before and now is higher, then progress is positive. In this case, we complete the cycle, remove the sensor, turn the screw again in the specified direction, and fill it with sealant. If this procedure produces the opposite result, for example, the water level has decreased even more, then we reverse the process. Unscrew the screw 1-2 turns in the opposite direction and repeat the test.

In most cases, properly adjusting the pressure switch will save the day, and the washing machine will continue to operate without problems filling or draining. The key is to not overtighten the screws and to restart the machine several times for best results.

The setting doesn't help

If the pressure switch shows external damage or adjustments fail, replacement is necessary. Fortunately, this is a quick fix, and the part itself is relatively inexpensive. You just need to purchase a sensor that matches the serial number, remove the old one and install the new one.

Before connecting a new pressure switch, it is recommended to carefully study the electrical wiring diagram of the washing machine.

- First, a new sensor is attached to the mounting location.

- Next, we connect the hose to the part and secure it with a clamp.

- We connect the wiring, referring to the electrical diagram.

At the end, run a test wash. If the error persists, the problem lies elsewhere, and it's best to contact a service center for a comprehensive diagnosis.

Interesting:

3 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

And where is this "first" screw? No diagram, no drawing.

Everything is simpler.

If everything is working properly and you just need to adjust it, take a bucket of water and pour it into the machine. Adjust the screw until it engages, without having to turn the machine on and off. Then, start the drain and that's it.

Now we've seen new pressure switches with a single screw, electronic ones with a coil, but if you turn it just one turn, the pressure increases. Then it won't let you start the car with the new program. What should you do about this?