DIY Washing Machine Drum Repair

If the breakdown of your automatic washing machine is due to the tub or a moving element within the tub, you'll have to disassemble the machine completely. First, you'll have to remove the tub, disassembling the machine body in the process, then disassemble the tub itself, and then reassemble everything. This is quite a labor-intensive job, so the repair should be done once and thoroughly, to avoid having to disassemble the machine again. To properly carry out the repair yourself from start to finish, read our article.

If the breakdown of your automatic washing machine is due to the tub or a moving element within the tub, you'll have to disassemble the machine completely. First, you'll have to remove the tub, disassembling the machine body in the process, then disassemble the tub itself, and then reassemble everything. This is quite a labor-intensive job, so the repair should be done once and thoroughly, to avoid having to disassemble the machine again. To properly carry out the repair yourself from start to finish, read our article.

What breaks in the washing machine tank?

The tub of an Indesit washing machine (or any other) is its main component, housing the drum and other moving parts. It's the tub that collects water and is essentially where the washing takes place, even though the laundry comes into contact with the walls of the drum, not the tub. At first glance, it seems the tub itself can't break, as it's just a reservoir. The moving parts within it are a different matter, but this is a common misconception. So, what can break in the tub of an automatic washing machine?

- Bearings. This is a moving element located in the tank. The bearings themselves cost next to nothing, but replacing them requires a lot of effort. This carries the risk of seriously damaging the shaft, pin, and other components.

- Shaft. May become deformed if bearings are not repaired.

- Tank walls. They can bend due to centrifugal force from contact with the drum, or if the shock absorbers and bearings are damaged. In the worst case, the walls can be damaged, compromising their seal.

- The tank drain hole. The hole itself, of course, can't break. However, a drain valve is installed on it, which can fail. Furthermore, the drain hole can become clogged and need to be cleaned.

Please note! If the bearing is not repaired promptly, it can lead to complete destruction of the tank due to a loose drum. After this, the tank will definitely need to be replaced!

Features of tank assembly and disassembly

The procedure for disassembling the drum of an automatic washing machine is similar in all cases. We'll be working with either a non-detachable or a disassemblable version. Disassembling the drum of a washing machine yourself is entirely possible, but you need to proceed with extreme caution. We've specifically chosen to describe the entire process using a non-detachable drum as an example, as it's somewhat more challenging.

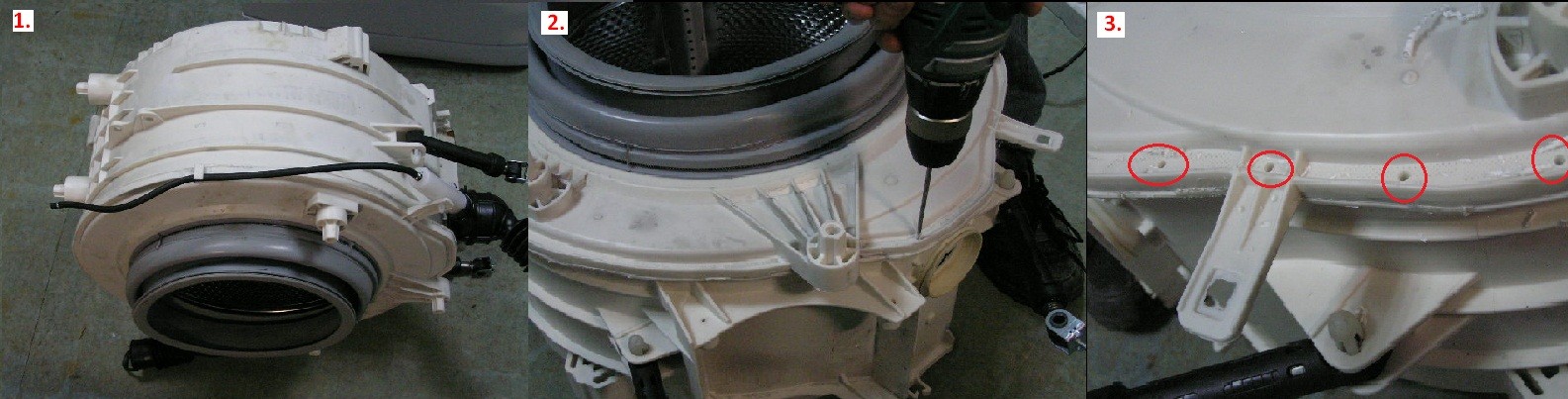

At the first stage, we carefully inspect the tank body from all sides. Our task is to determine the location of the soldered seam, as well as to mark the places where we will drill holes for future fasteners. After this, take an electric drill, a thin 3 mm drill bit and drill 15-20 holes in a circle, as shown in the picture below.

Now comes the crucial part: we need to carefully cut the welded seam of the tank body into two halves using a hacksaw. This job will take a considerable amount of time, so be patient and get started. This is how the non-separable tanks are transformed into collapsible ones.

Important! When sawing through the drum body, don't cut too deep—a maximum of 5 centimeters—as the body walls are thin. If the saw blade slips too deep, you risk damaging the drum walls.

Once the tank is cut, you should have two halves—a front and a back. The front is a small, irregularly shaped plastic ring with a hatch and rubber seal in the center. The back half of the housing contains the entire drum, complete with the drive mechanism, which can now be removed.

We take the rear half of the tank and turn it over with the drum hatch facing down. Now we need to disassemble the shaft without damaging its main fastening element—the screw located in its center. To unscrew it, you need to take a metal rod (a center punch works well), point it at the screw and hit the rod several times with a bronze or regular hammer. Next, take a Phillips screwdriver and unscrew the screw.

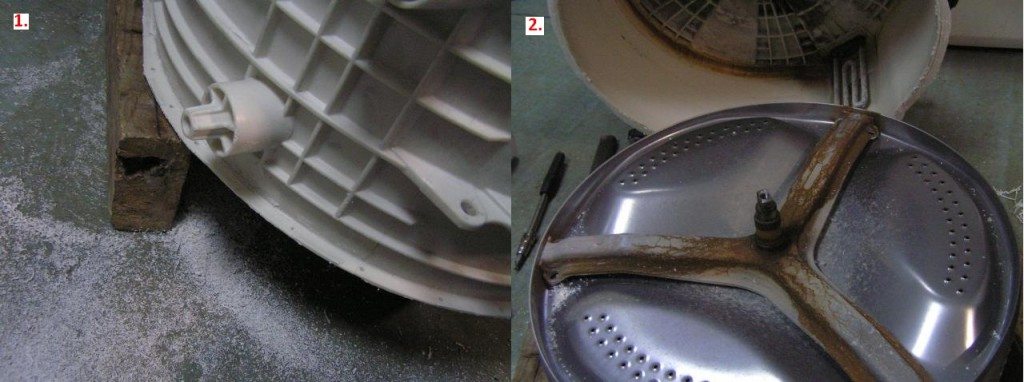

The next step in disassembling the tank involves properly removing the shaft from the piston rod. Here's how. First, take a small wooden block and two larger blocks. Place the larger blocks under the edges of the tank so that it rests more or less securely on them. Take a hammer and a small block, aim the block at the piston rod, and strike it several times with the hammer. The strikes are as follows: first lightly, then a little harder, then a little harder still. After this, the drum should separate from the tank body.

Please note! Don't hit the piston rod with all your strength using a block. The piston rod looks secure, but looks can be deceiving, so to avoid damaging the part, measure your impact force; it's better to be safe than sorry.

The next step involves removing the bearings from the tank body. If the bearings are in good condition and the problem is a warped or leaking tank, they can be left alone, as they won't interfere with the repair. However, if the problem is with the bearings and seals, they must be removed. Take a metal rod, point it at one end of the bearing, and lightly strike it with a hammer. Move the rod to the other end of the bearing and strike again. You cannot hit only one edge of the bearing, as it will expand and then have to be drilled out with a step drill. We extract and We replace both bearings with new ones.After replacing and repairing all faulty parts, reassemble the tank in reverse order. We seal the edges of the cut parts with sealant or cold weld and join them together. We then insert bolts through the pre-drilled holes and secure them with nuts. The bolt size will depend on the drill bit used.

You cannot hit only one edge of the bearing, as it will expand and then have to be drilled out with a step drill. We extract and We replace both bearings with new ones.After replacing and repairing all faulty parts, reassemble the tank in reverse order. We seal the edges of the cut parts with sealant or cold weld and join them together. We then insert bolts through the pre-drilled holes and secure them with nuts. The bolt size will depend on the drill bit used.

Troubleshooting

After successfully disassembling the tank, we begin the repair ourselves. We've already mentioned replacing the bearings, so we'll move on to repairing the tank body. Repairing damaged tank walls begins with an inspection and assessment of the nature of the damage. Much will depend on the material the tank is made of. If it's plastic, cracks may form, allowing water to leak through.

Some home-grown DIYers suggest soldering the crack and continuing to use the tank. In our opinion (and experts agree), such a solder won't hold up for long, and the machine will then need to be repaired again. It's better to buy a new tank body and replace it. A plastic tank body is cheaper than a metal one.

If the tank is made of stainless steel and a hole has formed in it, it can be welded shut and will still serve for some time. In this case, we recommend delegating the welding work to an experienced welder, who should do everything quickly and accurately. After welding, paint the weld with waterproof enamel—this will further extend the life of the tank. In general, there are no other adequate methods for repairing punctured metal tanks other than welding or complete replacement of the unit. No sealant or cold welding will help in this case.

To repair bent metal tanks of a washing machine, it is necessary to carry out repairs in the following order.

- Take a regular hammer and a wooden block. If the dent is small and the tank isn't punctured, nothing else will be needed.

- Using a gas burner, we heat the dent, heating the outer wall of the tank.

- Place a block on the bulge in the tank that matches the dent on the outside and, while the metal is still warm, lightly tap it with a hammer. The dent should straighten out.

Next, we need to check the drain valve and the tank drain hole for any defects or blockages. Here's what to do.

- Visually inspect the drain hole, removing lint, hair, caked dirt, and scale. If this isn't possible by hand, use sandpaper.

- We check the sealing rubber and the cuff of the drain valve of the washing machine tank. If the rubber has become hardened and cracked over time, both the cuff and the sealing rubber need to be replaced.

- Take a multimeter and check the drain valve contacts. If the resistance is 1, the unit is faulty. The valve needs to be replaced with a new one.

Important! Before checking the valve with a multimeter, be careful to thoroughly clean its contacts and only then take measurements.

In conclusion, it's worth noting that repairing the drum of an automatic washing machine is quite complex. You need to properly disassemble the machine, remove the drum, then disassemble the drum itself correctly before proceeding with the repair. It's not guaranteed that this repair can be done at home. Everything will depend on the type of breakdown.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment