Bosch washing machine motor repair

Self-repair of a Bosch washing machine motor isn't possible for all problems. Even a novice mechanic can replace worn-out brushes, but filing down the fins or adjusting the winding is far more difficult and risky. In any case, it's first necessary to diagnose the motor and pinpoint the problem. There are several ways to check the motor's functionality. We suggest reviewing all diagnostic options, as well as troubleshooting instructions.

Self-repair of a Bosch washing machine motor isn't possible for all problems. Even a novice mechanic can replace worn-out brushes, but filing down the fins or adjusting the winding is far more difficult and risky. In any case, it's first necessary to diagnose the motor and pinpoint the problem. There are several ways to check the motor's functionality. We suggest reviewing all diagnostic options, as well as troubleshooting instructions.

Options for conducting an inspection

Almost all Bosch washing machines are equipped with brushed motors, which spin the drum via a belt drive. The advantage of these motors is that they can be tested at home.The main thing is to study the engine's electrical circuit and remember safety rules. The connection in most commutator motors is organized according to the following scheme:

Thus, a specific sequence is followed. The 220 volts supplied to the motor first reach the control triac, after which the current flows to the reverse relay contacts (II or I), then to the stator winding and rotor. The signal to switch modes and vary the power is sent by the control board via the transformer and the contact groups of the control unit. The motor's acceleration speed is regulated by a tachogenerator located on the housing, and the outgoing friction force is smoothed by the electric brushes.

Bosch washing machines are equipped with collector motors, which require a belt drive.

The stator winding has two sections, reducing the risk of interference caused by sparks on the commutator. By reversing the polarity of the wire, the drum's rotation direction is reversed. When switching to the spin cycle, a dedicated tap is engaged. In this case, electricity is connected to one of the outer terminals and the tap itself. If the tap is omitted, the washing machine operates only in standard mode, with the shaft moving slowly and smoothly.

To test a brushed motor yourself, you need to apply electricity directly to the device. The discharge occurs when connected in series to the stator and rotor windings. A functioning motor will hum and begin to operate, and when shorted, you'll notice the circuit heating up. The connection diagram looks like this:

There's another option for engine diagnostics. We connect the stator and rotor windings as described above, but use a special autotransformer with a power output of over 500 watts as the power source. This method is considered safer, as it allows for better control of motor acceleration and a timely response to unforeseen situations. Ideally, it's a good idea to be on the safe side and include a 5 or 10 amp fuse in the circuit.

If a transformer isn't available, an electronic regulator is used. It makes it easier to control the power supplied to the load, preventing the motor from overheating. Interestingly, such a device can be made yourself: all you need to do is find the appropriate circuit diagram online.

Beginners find it easier to test the engine visually. For example, after starting the engine, they can assess how much sparking the commutator brushes produce. If there are a lot of sparks, there's a system malfunction—the engine needs to be disassembled and a more detailed diagnosis performed.

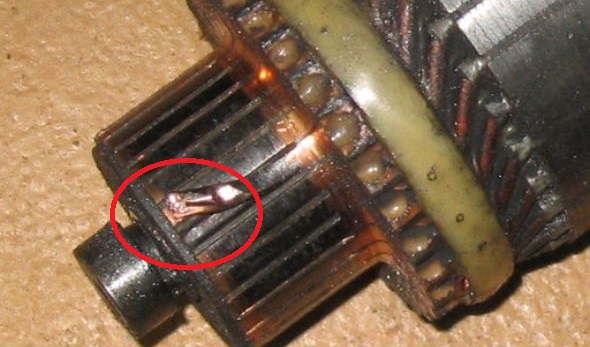

Peeling of lamellas

Motor failure is often caused by lost contact with a section of the rotor winding. This occurs if the motor fins or the wires adjacent to them are faulty. The current supplied to the motor either fails to reach the rotor at all, or its strength is significantly higher than the rated level. In either case, there is a risk of short circuit or overheating.

Lamels are metal plates that are glued to the commutator shaft and help transmit current through the circuit. When connected to the winding sections, special hooks are created to ensure better contact. However, during motor operation, wires often become caught on protruding elements and break. Repairs must restore the integrity of the device.

Operating an engine with peeling fins is dangerous – it can cause a short circuit with all the consequences.

Things get more complicated when the lamellas peel off. This type of failure is caused by excessive heating, which can occur due to a short circuit or rotor jamming. Current flows through the lamellas at a level exceeding the operating level, leading to overheating and peeling of the thin metal. Experience shows that peeling is most often caused by:

- faulty bearings that suddenly “stop” the motor;

- a running wash cycle with the drum flaps not locked in place in a vertical washing machine, which causes the system to suddenly stop.

The slats don't peel off without a reason. In fact, their peeling clearly indicates underlying engine failure or improper operation of the automatic transmission. It is necessary not only to fix the problem itself, but also to carry out “correction work”.

If the lamellas have peeled off only slightly, by 0.5 mm or less, then engine repair will be limited to turning the shaft on a special machine. This will require identifying all the delaminations, cleaning them, and then carefully inspecting the treated areas, removing dust and burrs.

You can confirm lamella detachment with a manual test. Simply rotate the rotor slowly with your palm and listen: if you hear a distinctive cracking sound, the lamellas are catching on the winding.

Changing brushes yourself

If the motor has stopped working due to worn brushes, the solution is simple: remove the old ones and install new ones. The first step is to arrange replacements and purchase similar parts. Parts are selected based on the serial number of the washing machine or motor. The ideal solution is to remove the damaged brushes and bring them to the store.

You can't just randomly choose electric brushes. Even Bosch washing machines use different types of parts: with and without housings, with central and corner contacts. To avoid mistakes, it's important to carefully examine the selection and tell the seller the brand and serial number of the machine. This is especially true if you're ordering a similar product online.

The brushes are mounted directly on the motor. To replace them, you must first remove the motor from the machine. Here's how:

- we move the back panel away from the case, having unscrewed all the provided bolts;

- we find the engine located under the drum;

- we remove the drive belt by pulling it towards ourselves while simultaneously turning the pulley;

- we release the wiring from the engine contacts;

- loosen the bolts holding the motor (an 8 mm wrench will do);

- We pull the engine out of its seat, rocking its body from side to side.

It is recommended to record all manipulations on a photo or video camera to avoid errors during reassembly.

Place the motor out of the washing machine on a flat, dry surface and continue the repair. Locate the two electric brushes attached to the sides of the housing, remove them, and inspect them. The procedure is as follows:

- disconnect the wire connected to the electric brush case;

- move the contact down;

- stretch the spring;

- pull out the brush.

Next, open the brush case and measure the carbon tip inside. If the tip is less than 0.7 cm long, it needs to be replaced. Insert the new tip into the socket, compress the spring, secure it in place, slide the contact upward, and connect the wiring.

The second brush is removed and installed according to similar instructions. It doesn’t matter whether it’s worn out or not – carbon rods are always replaced in pairs. Then we put the motor back in place and reassemble the washing machine, following the steps in reverse order:

- we insert the engine into the “socket” and secure it with fasteners;

- we connect the wiring;

- We tighten the drive belt, first putting it on the pulley, and then, turning it, on the large wheel;

- We assemble the case by screwing on the back panel.

All that's left to do is check the new electric brushes. Turn on the quick wash cycle and evaluate the motor's performance. If the motor starts and rotates the drum as usual, then everything is done correctly.

The windings are broken or shorted

Acceleration problems also arise with a damaged winding: the motor fails to start or rotates the drum very slowly. This occurs when short circuits occur in the wire windings, causing the motor to overheat, triggering the thermistor, and the system, for safety reasons, immediately cuts off power. The next time the motor is started, the situation repeats until the temperature sensor burns out, and then the motor itself fails.

The winding is checked with a multimeter according to the following algorithm:

- turn on the tester to the “Ohmmeter” mode;

- we attach the probes to the adjacent lamellas;

- We evaluate the resistance (normal – from 0.1 to 0.4 Ohm).

Repairing the winding yourself is very dangerous. It's best to contact professionals or purchase a new motor.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment