LG washing machine motor repair

Among the LG washing machines that require repair and are sent to service centers, a significant proportion are units with three-phase brushless motors, or motors using inverter technology. Although these units break down less frequently than brushed motors, they do sometimes fail. How does this type of motor work, and is it possible to repair an LG washing machine motor yourself, at home?

Among the LG washing machines that require repair and are sent to service centers, a significant proportion are units with three-phase brushless motors, or motors using inverter technology. Although these units break down less frequently than brushed motors, they do sometimes fail. How does this type of motor work, and is it possible to repair an LG washing machine motor yourself, at home?

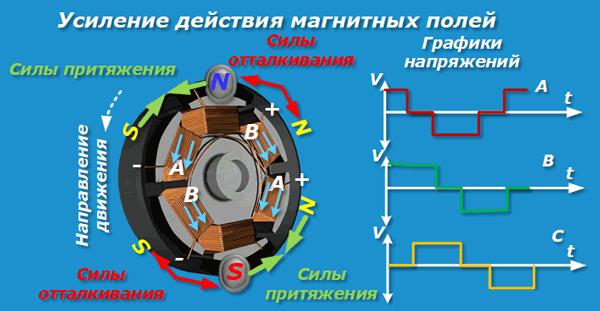

How does an inverter "engine" work?

A distinctive design feature of LG washing machines is the way the motor is mounted. It is connected directly to the drum, without a pulley or belt. The motor is secured with a special coupling, which drives the laundry container. This design and the lack of additional components allowed the manufacturer's engineers to reduce the machine's overall dimensions. Compared to other washing machines, LG's appliances are compact.

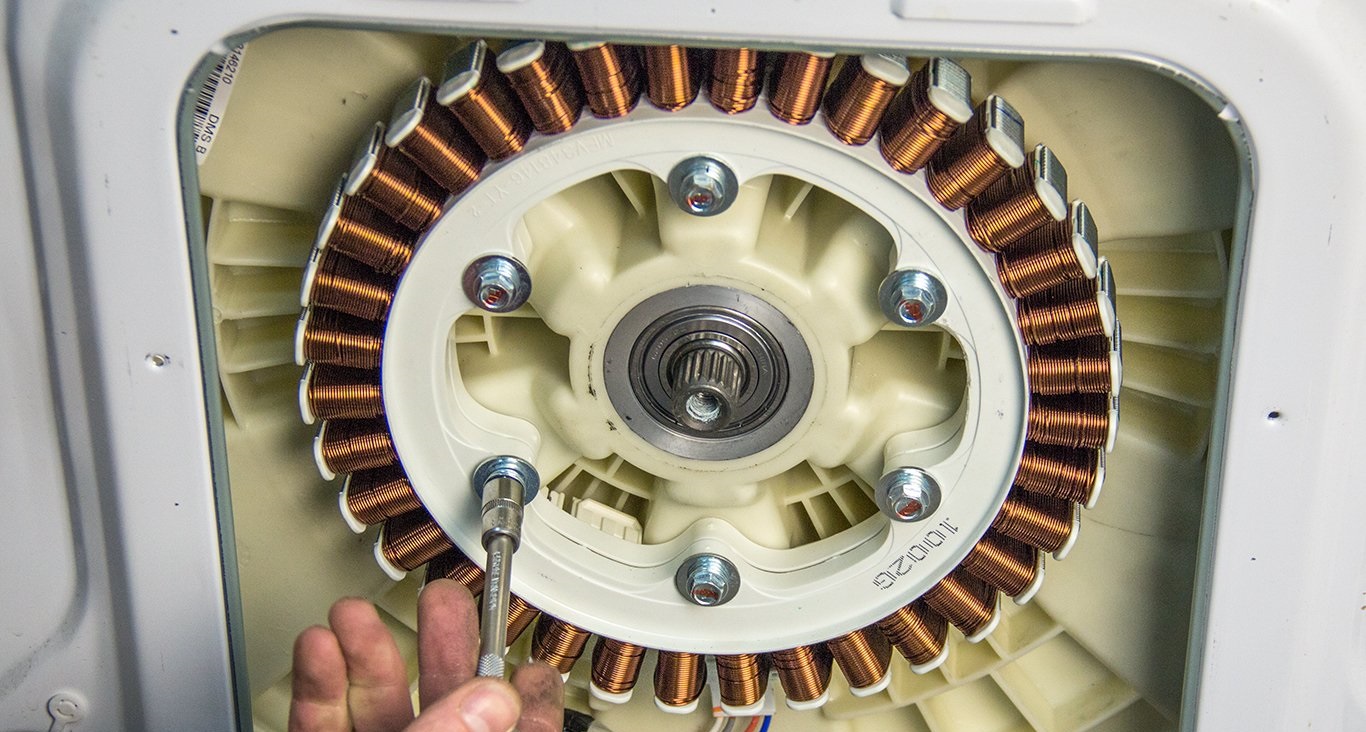

It is usually equipped with three-phase brushless motors. Their design includes a rotor and a stator with 36 induction coils. The rotor is attached to the washing machine drum so that its shaft also serves as the drum shaft. The electric motor is controlled by signals received from the electronic module.

How to remove the engine and is it worth repairing?

Companies that manufacture washing machines with inverter motors do not recommend attempting to repair them yourself. Manufacturers recommend contacting professionals for a system diagnostic. This procedure will help determine the cause of the malfunction and fix it.

Important! Before beginning any diagnostic work, make sure there is no laundry left in the drum and remove the door.

To remove the inverter, you need to do the following:

- disconnect the washing machine from the power supply;

- Remove the back panel from the device body by unscrewing the bolts holding it in place. Locate the screws located under the rotor. These are used to secure the wiring. These screws must be removed.

- Before disconnecting the wires, you should record their correct location. You can draw a diagram or take a photo;

- Remove the central rotor retaining bolt. When doing this, proceed carefully and hold the components to prevent them from rotating;

- remove the rotor first, then the stator;

- Disconnect all wire connectors one by one.

Once the motor is removed, you can check its functionality. Experts recommend inspecting the rotor winding for damage. If necessary, it can be rebuilt. This is difficult to do yourself; you'll need the services of a specialist. Keep in mind that this is an expensive service, so many washing machine owners opt to replace the entire electric motor.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment