Samsung washing machine motor repair

Repairing a Samsung washing machine motor yourself isn't always possible. While replacing worn brushes is something even an inexperienced technician can handle, grinding down the fins or adjusting the windings are more complex and sometimes risky tasks. The first step in dealing with a motor malfunction is to diagnose and determine the cause of the problem. Let's look at how to do this correctly.

Repairing a Samsung washing machine motor yourself isn't always possible. While replacing worn brushes is something even an inexperienced technician can handle, grinding down the fins or adjusting the windings are more complex and sometimes risky tasks. The first step in dealing with a motor malfunction is to diagnose and determine the cause of the problem. Let's look at how to do this correctly.

Comprehensive engine check

Many Samsung washing machine models are equipped with brushed motors. They rotate the drum via a belt drive. These motors have an important advantage: owners can test them at home if they wish. The only requirement is to follow safety precautions and be familiar with the motor's electrical circuit.

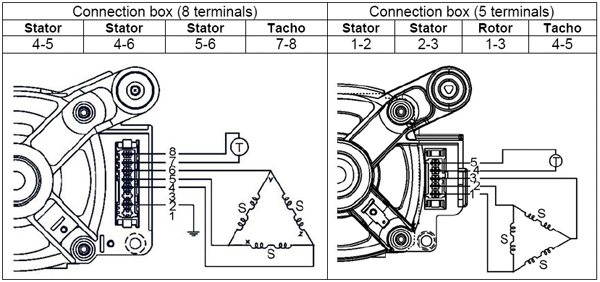

In brushed electric motors, the connection is made according to a specific circuit. The supplied current is fed to a triac, then sequentially to the contacts of the reversing relay, the stator winding, and the rotor. When switching operating modes or changing power, a signal is transmitted from the control board through the contact blocks of the control unit and the transformer. The motor's acceleration speed is regulated by a tachogenerator, located on the motor housing. Electric brushes are provided to smooth out friction.

The stator winding's two sections reduce the risk of interference from sparks on the commutator. The drum's rotation direction is reversed by reversing the polarity of the wire. A tap is provided when switching to spin mode. Power is connected to the outer terminal and directly to the tap. When the tap is omitted, the washing machine operates on a standard program, with smooth and slow shaft movements.

To diagnose a commutator motor yourself, you need to supply electricity directly. The discharge occurs sequentially when connected first to the stator winding, then to the rotor winding. If the motor is working properly, it will begin to hum and run. If a short circuit occurs, the circuit will noticeably heat up.

Another way to test the motor is to connect the stator and rotor windings as described above, then use an autotransformer with a power output exceeding 500 watts as a power source. This option is considered safer by mechanics, as it allows for precise monitoring of the motor's acceleration and a quick response if an unexpected situation arises.

Important! When performing diagnostics using this method, to be on the safe side, include a 10 or 5 amp fuse in the circuit.

If a transformer isn't available, an electronic regulator can be used. It makes it easier to control the load and prevent the motor from overheating. Sometimes, professionals build such devices themselves. Schematics for these devices are easy to find online.

Beginner mechanics can visually assess the engine's performance and health by starting it and observing the commutator brushes sparking. If a large number of sparks appear, it means that a breakdown has occurred. The next steps to take are to disassemble the engine and perform extensive testing.

Is it possible to restore the slats?

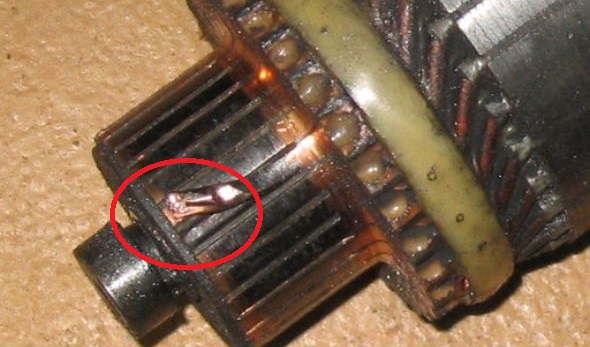

Electric motor failures are often caused by loss of contact with a section of the rotor winding. This occurs when the motor fins or the wires located near them are damaged. The fins are metal plates connected to the commutator shaft and transmit current through the circuit. If the fins are faulty, the current stops flowing to the rotor or its strength becomes significantly higher than the rated level. This results in the risk of short circuits or overheating.

When connecting the lamellas to the winding sections, hooks are created, making the contact more reliable. However, during operation of the electric motor, the wires can become caught on protruding parts and break. In this case, repair involves restoring the integrity of the part.

It is unsafe to turn on a washing machine with detached slats, as there is a risk of short circuit.

Detached lamellas are a result of overheating, which occurs when the rotor jams or shorts. Current flows through the metal lamellas at a level higher than the operating level. As a result, the thin metal overheats and peels off. Among the most common causes of lamella detachment, technicians cite the following:

- damage to the bearings that “stop” the motor;

- In top-loading machines – the drum flaps become unlatched after the wash cycle starts and the machine suddenly stops working.

Detached slats often indicate underlying problems or improper operation of the washing machine. Detachment of metal slats always has its causes. It's important not only to repair the motor but also to check that the appliance is being used correctly.

If the lamella delamination is minor, with a gap of no more than 0.5 mm, resurfacing the shaft can help correct the problem. This is performed on a specialized machine. The technician locates all the delaminations, cleans them, and carefully inspects the part again, removing any burrs or dust particles.

A simple test can help detect fin separation. You can do it yourself. Slowly crank the motor and check for a clicking noise. This indicates that the fins are rubbing against the winding.

Problems with the winding

A faulty winding can sometimes cause acceleration problems. The motor may not start at all, or the drum may spin too slowly. When short circuits occur in the windings, overheating occurs, the thermistor is triggered, and the power supply shuts off. When the washing machine is restarted, this process repeats. This continues until the temperature sensor burns out and the motor itself fails.

To diagnose a winding fault, you need to use a multimeter. Follow these steps:

- turn on the device, set the “Ohmmeter” mode;

- connect the probes to the adjacent lamellas;

- The multimeter should display a resistance value. Normally, it should vary between 0.1 and 0.4 ohms.

If the winding is damaged, it can be repaired. However, repair is often not cost-effective. It's easier and cheaper to replace the entire part.

It's all about the brushes

If the motor malfunction is caused by worn brushes, the problem is easy to solve. Simply remove the damaged parts and install new ones. To do this, you'll need to purchase similar brushes. When choosing, you need to focus on the serial number of the machine or engine. To avoid mistakes, you can take your old parts with you to the store. The salesperson will help you find the right ones based on the serial number. Electric brushes can have corner or center contacts, with or without a housing.

Buying parts at random is not a good idea, as even Samsung car models are equipped with different spare parts.

To replace the brushes, you need to remove the motor. Follow these steps:

- unscrew the bolts holding the rear panel of the washing machine body;

- Find the electric motor. It is located below the drum;

- Remove the belt. To do this, pull it towards you and simultaneously turn the pulley;

- release the wiring from the contacts;

- loosen the bolts that hold the engine;

- Remove it from its mounting location. Proceed carefully, rocking the engine housing from one side to the other.

Experts advise beginners to film or take photos of the part removal process to avoid making mistakes when reinstalling the engine.

Place the removed motor on a flat, dry surface. Then you can begin replacing the brushes. They are attached to the sides of the housing. To remove the parts, disconnect the wire leading to the housing, move the contact downward, and stretch the spring. After this, the brushes can be removed one by one.

Open the case and measure the carbon tip inside. If the length is less than 0.7 mm, the brush needs to be replaced. Insert the new carbon rod into the socket. Then compress the spring, secure the part in place, slide the contact upward, and connect the wiring.

If during repair it turns out that only one electric brush is worn out, it is necessary to replace both carbon rods; they are always installed in pairs. Once the brushes are replaced, you can install the motor and reassemble the washing machine. Here's how to proceed:

- the engine is placed in the “nest” and secured with bolts;

- the wiring is connected;

- put on the drive belt;

- close the case with the back panel, screwing in the retaining bolts.

The repair work concludes with a test of the new brushes. To do this, turn on the quick wash program. If the motor starts and the drum rotates smoothly, the machine is in good working order.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment