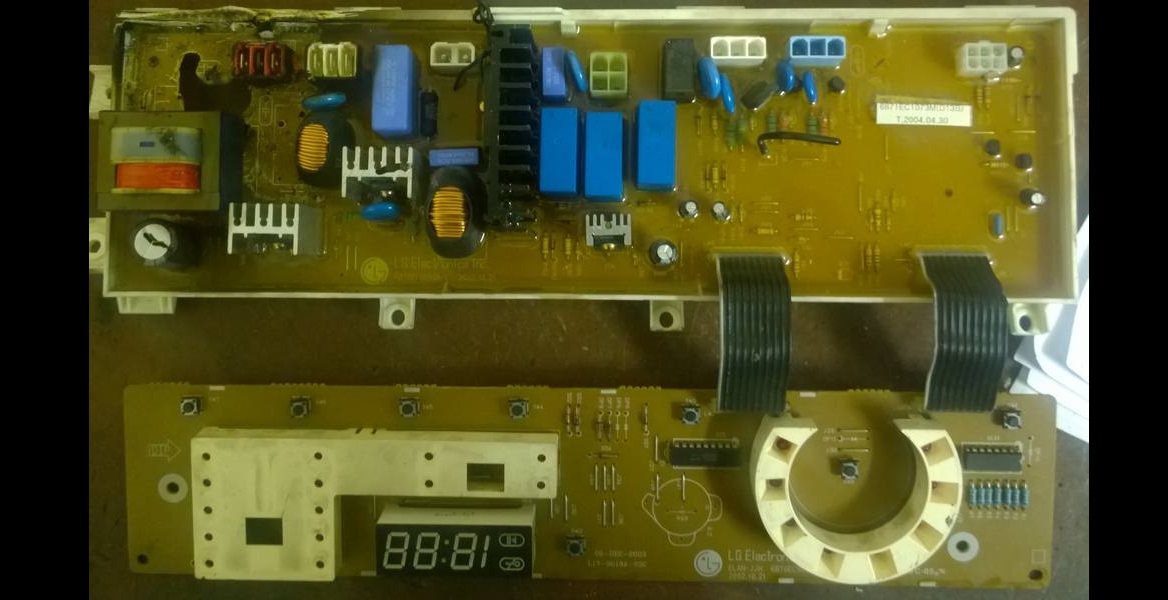

LG washing machine electronic module repair

Repairing a washing machine's control module requires specific skills and knowledge. If you've never seen a microchip or handled a soldering iron, it's best to leave this job to a professional. If you have at least some experience, you can try to handle the task yourself.

Repairing a washing machine's control module requires specific skills and knowledge. If you've never seen a microchip or handled a soldering iron, it's best to leave this job to a professional. If you have at least some experience, you can try to handle the task yourself.

Repairing an LG washing machine's electronic module is a two-step process. First, you need to remove the circuit board and locate the burned-out component. The second step involves replacing the semiconductor. Let's explore the details.

Which part is responsible for what?

When you first look at an LG washing machine's control module, you might be surprised by how many semiconductor components it contains. Checking each one would be time-consuming, so it's important to understand which sensors are responsible for what. Then you can correlate this information with the symptoms of a malfunction and detect the defect faster.

Basically, the LG automatic washing machine module consists of two parts: the control panel and the power unit. To access the circuit board itself, this part must be disassembled. Under the casing and compound there are semiconductor elements that control the operation of various washing machine components.

Each semiconductor element is responsible for the operation of certain components of the LG washing machine.

Therefore, to avoid checking every single semiconductor, consider what exactly you were dissatisfied with about the machine's operation. If it simply stopped turning on, you'll need to test the sensors responsible for powering the appliance. If there were problems with the inverter motor, pay close attention to the HS1 power assembly, which controls the drive motor. Let's take a look at each step.

On the left side of the control module are the elements responsible for powering the machine. These are:

- integrated stabilizer KIA7805, on the board it is designated U14;

- pulse converter based on the STR-A6059M PWM controller;

- network rectifier and filter (labeled BD1 and CE4);

- protective varistor (Z2);

- network fuse;

- key converter microcircuit (labeled U12);

- SMPS pulse transformer;

- diode D13, capacitor CE2;

- diode D11, capacitor CE8, power supply channel 9V;

- diode D12, capacitor CE9, power supply channel 12V;

- diode D14, capacitor CE6, power supply channel 12V;

- diode D6, zener diode ZD1, transistor Q1, resistor R103;

- resistor R74, aka 205;

- optocoupler U15, transistor assembly U3;

- U13 processor;

- relay X1 (it is also connected in series to the heating element circuit);

- integrated voltage stabilizer 5V, designated U

The next element on the control board is the temperature sensor. This includes the following semiconductors:

- contact 4 (TH1) of connector RD6;

- resistor R12;

- 37th leg of the U processor

The following semiconductors of the module are responsible for the operation of the heating element:

- relay X1;

- 64 pin of U13 processor;

- 1 and 16 legs of U3 assembly;

- relay X2;

- 24 leg of U13 processor;

- transistor Q7.

The module also features a backup relay control channel. Components are optional. These include the following semiconductors:

- 75 leg of U13 processor;

- resistor R83;

- transistor Q5;

- relay X4;

- second contact of the BL connector

The following persons are responsible for the operation of the pressure switch:

- resistors R6, R7;

- 67 leg of the U13 processor.

The next block of semiconductors is responsible for the operation of the pre-wash compartment valve. These are:

- 29 leg of U13 processor;

- 4 and 13 legs of U3 assembly;

- resistor R25, R29;

- optocoupler U8;

- triac TR3;

- contact 1 of connector YL4.

The following are responsible for the functioning of the main wash compartment valve:

- 31 legs of U13 processor;

- 6 and 11 legs of U3 assembly;

- resistor R23, R27;

- optocoupler U6;

- triac TR5;

- contact 4 of connector YL4.

The following circuit provides control of the hot water inlet valve:

- 31 legs of U13 processor;

- 6 and 11 legs of U3 assembly;

- jumper J1;

- resistor R24, R28;

- optocoupler U7;

- triac TR4;

- second contact of YL4 connector.

The operation of the washing machine drain pump is controlled by semiconductors:

- 61 legs of U13 processor;

- resistor R77, R79, R82;

- transistor Q4, Q3;

- optocoupler U4;

- triac TR20;

- contact 4 of connector BL4.

If you are experiencing problems with your washing machine's hatch locking device, please check the following block of elements:

- 27 leg of U13 processor;

- 2 and 15 legs of U3 assembly;

- resistor R21;

- optocoupler U2;

- relay X3;

- contact 1 of connector BL4.

The following are responsible for the operation of the Hall sensor, which monitors the engine speed:

- contacts 4 and 6 of connector BL6;

- resistor R44, R60;

- 3,4,5,6 pins of the U1 microcircuit;

- 19.20 processor pin U

If your washing machine motor stops working, test the following circuit:

- 17 leg of the U13 processor – power assembly HS1 (output stages and drivers) – microcircuit U1;

- comparator from the microcircuit U11 – storage choke RA – resistor R58, R57;

- 6.7 pins of comparator U11 – control of supply voltage 300V, the signal goes along the circuit with diode assembly BD1, resistor R70 and 41 pins of processor U

Resistors R73, R72 and 73, 74 pin of processor U13 are responsible for the operation of the program switching selector.

As you can see, there are plenty of semiconductor elements on the board, so repairing the control module may be overwhelming for beginners who don't know anything about microcircuits. If concepts like resistors, relays, and optocouplers are familiar to you, and you have a general understanding of how circuits are built, you can try to repair the unit yourself.

Typical problems

A damaged electronic module is a rare problem with LG washing machines. Typically, the culprit isn't the control unit, but rather a component or sensor. For example, if the machine won't turn on, don't immediately disassemble the circuit board—first check the outlet, power cord, plug, noise filter, and start button.

However, in rare cases, the problem will actually be with the control module. We'll explain how to check the board for any type of washing machine malfunction.

- The washing machine won't turn on, but the indicator on the electronic module is lit. First, check the power-on signal circuit to see if it's being sent to pin 63 of processor U13 (via optocoupler U15 and pins 13 and 14 of U3) after pressing the button. If all is well, test the 9V power supply to see if the specified voltage is reaching relay coil X1.

- The car starts, but the display shows an LE error while the engine is running. This malfunction is usually caused by damaged Hall sensors and their circuits. The current-limiting SMD resistors in the module will need to be checked and replaced. First, you'll need to remove the compound from the tachometer module.

- The washing machine turns on, but the motor doesn't run. The display shows a PF error. This failure is typically caused by a lack of 300V power on the HS power assembly. First, check the integrity of fuse FUSE1, then the semiconductors in the BD1 circuit, the HS1 assembly, and resistor R70 on pin 41 of the U13 processor.

- If the CE error appears after turning on the washing machine, there is a current overload in one of the output stages of the assembly or a defect in the control circuit (resistor R58, R57, pins 6 and 7 of comparator U11 to pin 17 of processor U13). In this case, the HS assembly will need to be replaced. It's also worth checking the integrity of the motor windings; interturn short circuits may be the cause.

- The machine turns on, but the cycle doesn't start due to error de. This means the door isn't locked. The functionality of optocoupler U2 and all its circuit components (connector BL4, resistor R21, pin 27 of processor U13) is checked.

- If the washing machine refuses to drain water, and all possible blockages in the hoses, sewerage system, and pump failure have been ruled out, the following block of elements is tested: resistors R77, R79, R82, transistor Q4, Q3, optocoupler U4, triac TR

Before testing the control module, make sure that the problem is not caused by faulty washing machine components. Only when the failure of other parts has been excluded, start diagnosing the control board. It is not necessary to check all semiconductors, but only those that correspond to the “symptoms” of a malfunction.

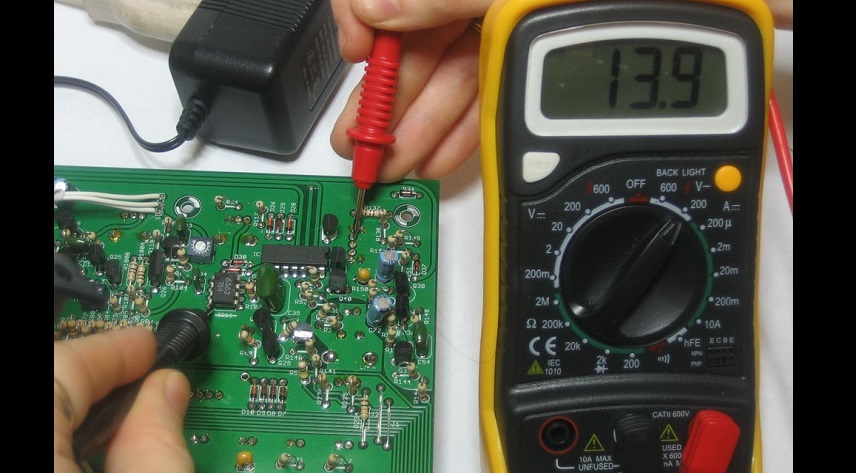

Checking and replacing the faulty element

Checking and repairing the washing machine control module is complicated by the fact that the circuit board is encapsulated in compound. Furthermore, the unit is often protected by a casing, which also needs to be removed. Here's the procedure:

- Run a flat-head screwdriver around the inside perimeter of the casing to remove any sealant from the edges of the board;

- make a deep groove around the perimeter of the module in the gap between the board and the casing;

- Insert a thin screwdriver between the casing and the control board in the corner where the power transformer is located. Gently lift the unit out of the casing. Be careful not to damage the microcircuit.

- After removing the board, remove any remaining sealant from it;

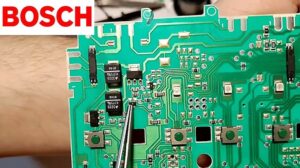

- repair the required section of the board (usually the damaged semiconductor element is soldered out and replaced with a similar one);

- cover the area with a protective varnish, for example, Plasik70 (for installation work).

Experienced repairmen do not remove the protective cover entirely, but cut a hole in it that provides access to the damaged area.

For example, a technician realizes the problem lies in the semiconductors responsible for the drain pump. Rather than remove the entire housing, they cut a hole in the lower right corner. This allows them to test the relevant components.

Handling the electronic module of your LG washing machine requires extreme caution. Removing the circuit board from its housing can damage the microchips. Therefore, if you're unsure of your skills, it's best to take your washing machine to a service center for repairs.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment