Whirlpool washing machine pump repair

The pump of a Whirlpool washing machine is constantly under heavy load, pumping wastewater from the tank into the sewer. This part is subject to significant wear and tear, so it can fail over time. Is it possible to repair a Whirlpool washing machine pump? How can I check and repair it? Let's explore the details.

The pump of a Whirlpool washing machine is constantly under heavy load, pumping wastewater from the tank into the sewer. This part is subject to significant wear and tear, so it can fail over time. Is it possible to repair a Whirlpool washing machine pump? How can I check and repair it? Let's explore the details.

Does the pump need repair?

A broken pump isn't always the cause of a malfunctioning drain. Other problems with the drainage system are also possible. Therefore, before repairing or replacing the pump, check all the Whirlpool washing machine's weak points.

- Clean the dust filter. A clogged filter element is often the cause of a machine's inability to drain water from the drum. The dust filter is located in the lower corner of the Whirlpool washing machine, behind a decorative panel or a special access door. Unscrew the coil and clean it and the resulting opening of any debris and dirt. Coins, buttons, and even socks can often be found inside. After removing any foreign objects, replace the plastic part and run a test cycle.

- Inspect the drain hose. The hose may be kinked or clogged. Carefully examine the hose, or better yet, disconnect it from the washing machine body and the drain connection, then rinse it under warm running water. Then run a test drain. If the machine continues to act up, further diagnostics will be necessary.

- Check the impeller's operation. To do this, unscrew the debris filter and look into the resulting hole. The impeller will be visible. Check to see if any foreign objects are caught between the blades. Also, remove any tangled threads or hair. Spin the impeller with your fingers; it should rotate freely. If movement is not restricted, the problem is most likely with the pump itself.

Before repairing the Whirlpool washing machine pump, check that the debris filter and drain hose are not clogged, and that the impeller is not rotating properly.

You can tell if the drain pump is working properly by listening to it. So, start a wash cycle and listen to the sounds your Whirlpool machine makes. If the washing machine starts making a loud humming noise while draining, but the water doesn't drain into the drain, it could be a sign of a faulty pump. Complete silence will also indicate a breakdown, as a measured and indistinct noise should still be present.

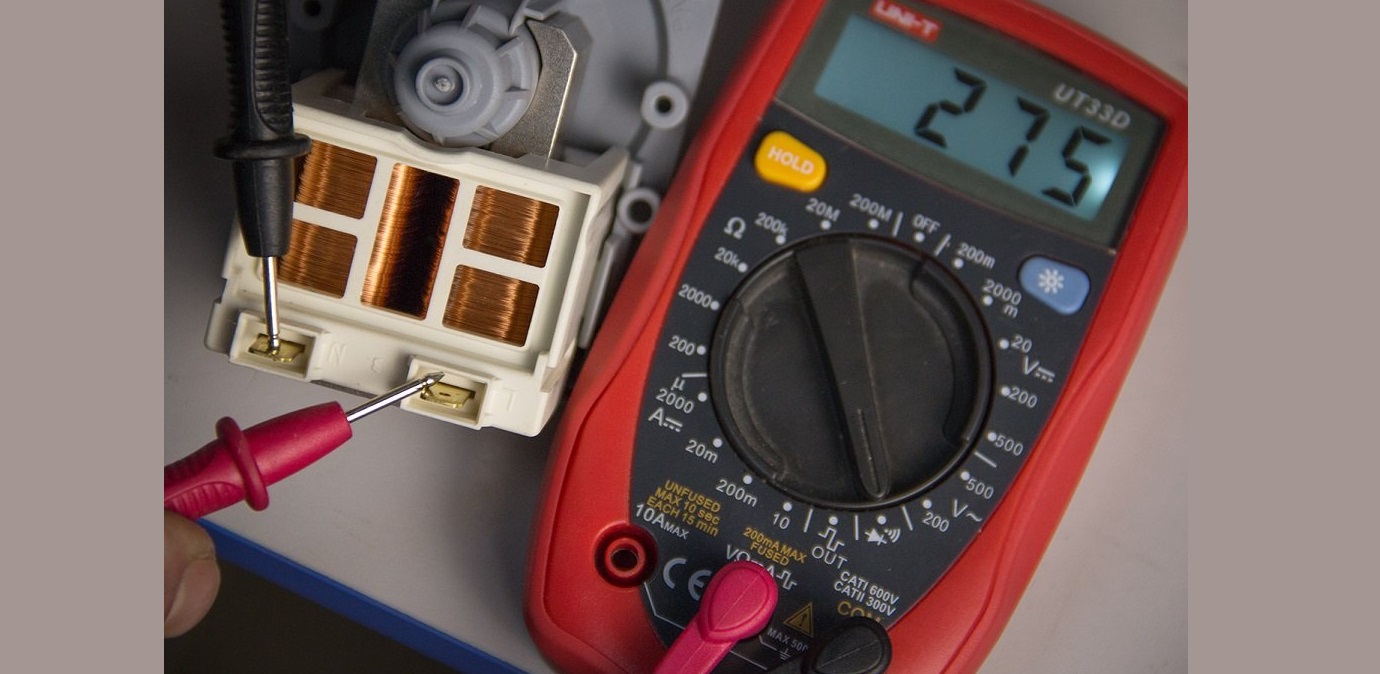

To diagnose the pump, you'll need a multimeter. It can be used to test the integrity of the stator winding. Visually inspect the pump contacts and sensors; they should show no signs of damage.

Another possible cause of a lack of drainage is the washing machine's control board. However, the electronic module rarely fails, so you'll likely need to replace the drain pump. Let's figure out how to repair the washing machine.

Consumables for pump repair

No special tools are required to repair or replace a washing machine pump. A standard Phillips-head screwdriver is sufficient. A pocket knife may also be useful; it's best to have one on hand.

To diagnose the pump, you'll need a multimeter. You can buy one at hardware stores or order one online. The tester is inexpensive, with models available for $2.50–$4.

The number of parts needed to repair a Whirlpool washing machine directly depends on the extent of the damage. In the worst-case scenario, you'll need to purchase:

- pump;

- impeller;

- pump sensor;

- sealant;

- contacts;

- axis;

- gasket;

- pulley.

As mentioned earlier, this is a spare parts kit for the worst-case scenario of pump failure. In most cases, simply purchasing a new pump is sufficient. How do you select replacement components?

When purchasing spare parts, please refer to the Whirlpool washing machine model and serial number of the appliance.

You can also dismantle the broken pump and take it to the store. The salesperson will select a similar part based on the part's markings. When ordering a pump online, verify all the information yourself to ensure you buy the right components for your Whirlpool model.

We get to the pump

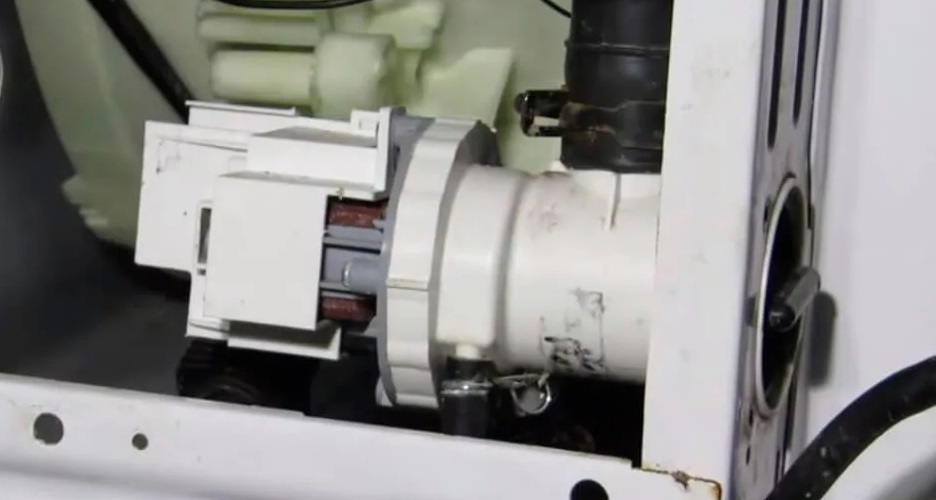

The pump is located in the same place on all Whirlpool models—at the bottom of the housing, regardless of whether it's a direct-drive or belt-drive model. You don’t even have to disassemble the washing machine to get to the pump. Enough:

- de-energize the automatic machine;

- close the shut-off valve;

- disconnect the device from the water supply and sewerage system;

- drain the remaining water from the system by unscrewing the debris filter;

- cover the floor with a blanket;

- place the washing machine on its left side, on a soft surface;

- remove the tray (if present).

Be sure to keep in mind that water will leak out of the opening when you remove the dust filter. Therefore, cover the floor in this area with rags or place a shallow container under the washing machine.

All that's left to do is look inside the washing machine and locate the pump. Now you can diagnose the component and, if necessary, replace it. If you're unsure about the repair, it's best to contact a service center for help.

First, the part is tested with a multimeter. The tester's probes are placed against the pump contacts, and the readings on the device's screen are then evaluated. Normally, the resistance reading should be 150-250 ohms.

We are looking for a problem during disassembly

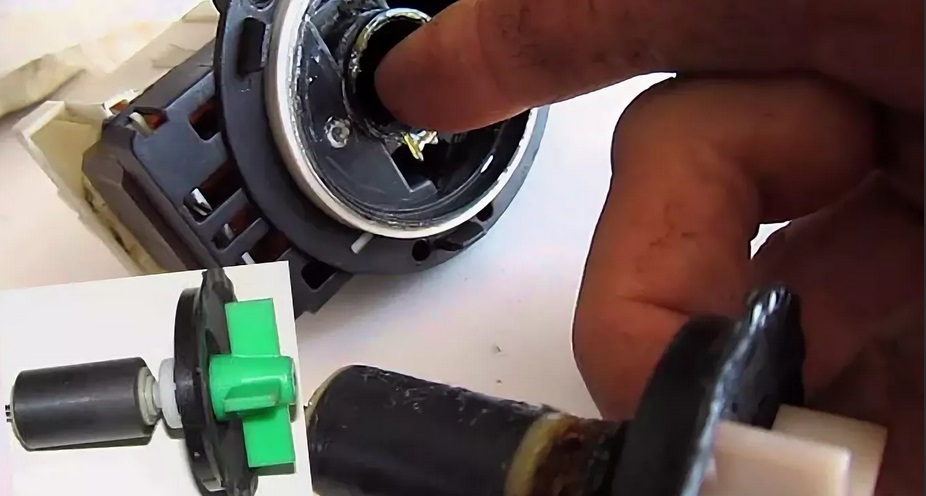

A key step is disassembling the pump. Only then can you determine whether the impeller rotates and how securely it is held in place by the clamps. An internal inspection is necessary if the blades are difficult to move, but there are no visible obstructions such as debris or foreign objects.

Whirlpool machines may use standard pumps, which are considered disassemblable, or non-disassemblable components. In the former case, proceed as follows:

- detach the pump from the volute by removing the fixing bolts;

- press on the part from the side where the drain valve is located, then pull the housing towards you;

- drain the accumulated water from the housing;

- pry up the retaining clips located on both sides of the pump;

- remove the pump from the reel.

Even non-detachable pumps can be broken in half. In this case, proceed with caution. The procedure is as follows:

- put on protective gloves;

- detach the pump body from the snail and coil;

- take a hair dryer and set it to the lowest temperature setting;

- Warm up the pump "tail" (this is the long tip located at the back) for a few minutes;

- Use a screwdriver to pry up the crosspiece and remove it from the housing;

- Also remove the magnet, which is why the structure is considered non-disassemblable;

- clean the magnet and its seat from debris, plaque and dirt;

- remove the magnet from the pump shaft.

Sometimes, cleaning the pump's internals is all that's needed to fix it. You can try removing debris, lubricating the magnetic bearings, and reassembling the part. If these steps fail, the pump will need to be replaced.

Before installing the new pump, be sure to clean all components of the drainage system. This includes the volute, the connected pipes, and the mounting surface. The component is secured with the bolts removed during disassembly.

Once you've installed the new pump, be sure to test the washing machine. Run an empty cycle with no laundry in the drum. A short "Rinse and Drain" cycle will suffice. If water drains freely, the repair is complete.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment