DIY washing machine programmer repair

The programmer is one of the most important control components in a washing machine, responsible for selecting the desired wash cycle, including spin, soak, and, in newer models, drying. Also called a control unit or timer, the programmer is used in most automatic washing machines and appears as a protruding round knob on the control panel.

The programmer is one of the most important control components in a washing machine, responsible for selecting the desired wash cycle, including spin, soak, and, in newer models, drying. Also called a control unit or timer, the programmer is used in most automatic washing machines and appears as a protruding round knob on the control panel.

Only machines with a microprocessor and the presence of a programmer can do without a programmer. fuzzy logic functionsThese units are controlled via a touch or button panel. If the programmer fails, washing is impossible. But how can you tell if this component is the problem, and whether it can be repaired yourself? We suggest you explore this together.

The device of the programmer

The programmer is an important component of the washing machine's control unit, which consists of a large number of parts.

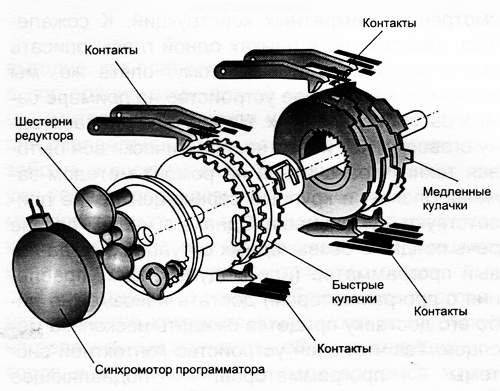

These parts can break over time, meaning they may require repair. But to carry out such repairs, you need to understand the programmer's design. The electromechanical control unit of an automatic machine includes the following main components:

- synchromotor;

- gearbox;

- contacts;

- gears;

- cams (protrusions and recesses) that drive the synchromotor.

There are two types of programmers:

- hybrid;

- electronic.

The hybrid command apparatus is considered the most reliable, but its functionality is limited. The electronic control units of automatic transmissions are more sophisticated, offering a wide range of functions and fine-tuning. However, they are prone to more frequent breakdowns, can react to power surges, malfunction, and shut down randomly.

Signs of a breakdown and its causes

A programmer failure can be determined by several signs:

- If the machine stops turning on and the electrical network is fine, then the cause of the malfunction may be caused by one of the elements of the control unit, including the command device;

Before disassembling the machine, be sure to check the power cord and socket for any short circuits.

- During washing, the program gets confused and the time does not correspond to the selected mode;

- In some models of washing machines, an external sign may be the flashing of all indicators on the control panel.

Even though the control unit is a fairly reliable part of a washing machine, it can still break down after 10 years. The main reason noted by the technicians is the users' careless handling of the unit. For example, if a child approaches the washing machine while it's washing and starts turning the handle, this could be enough to cause the programmer to malfunction.

Even though the control unit is a fairly reliable part of a washing machine, it can still break down after 10 years. The main reason noted by the technicians is the users' careless handling of the unit. For example, if a child approaches the washing machine while it's washing and starts turning the handle, this could be enough to cause the programmer to malfunction.

Another cause of failure is power surges in the electrical network. Furthermore, moisture getting inside the programmer can also cause malfunction. Manufacturing defects also cannot be ruled out.

Disassembling the programmer

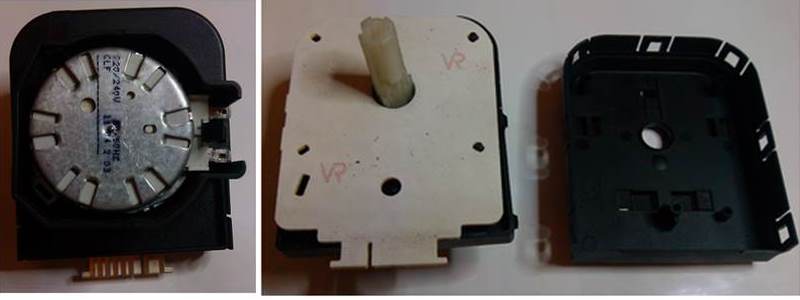

We begin programmer repairs with proper disassembly. The problem is that there are quite a few different types of programmers, not to mention the models themselves, each with its own disassembly requirements. We'll explain the disassembly process using the example of a programmer from an Ariston automatic washing machine. The procedure is as follows:

- We take the programmer removed from the machine and carefully inspect it. We find the clips on the side holding the plastic cover in place, pry them off with a screwdriver, and remove the cover.

Important! When removing the cover, be extremely careful. There are several small springs underneath that tend to fly apart when disassembling the programmer. Be careful not to lose them.

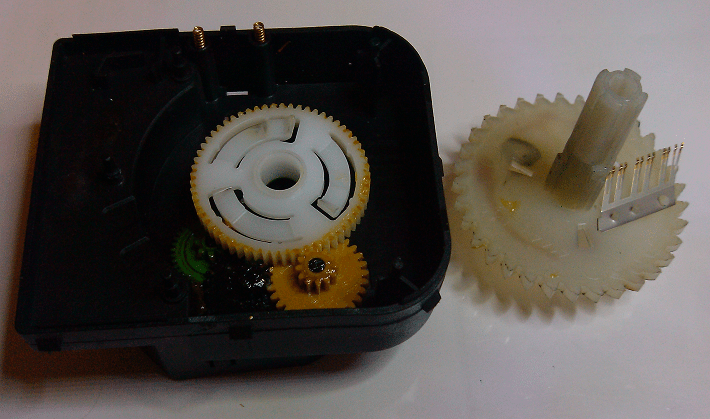

- Once we remove the cover, we'll see an upside-down board underneath. Carefully remove it and set it aside.

- We remove the central gear and inspect the small gears. They often become clogged with debris, which prevents the mechanism from operating properly.

- Now carefully inspect the board. You can often see burnt components or tracks. These will need to be re-soldered.

- If there are no burnt tracks, then we take a multimeter and measure the resistance on the contacts of the control board; we’ll find something.

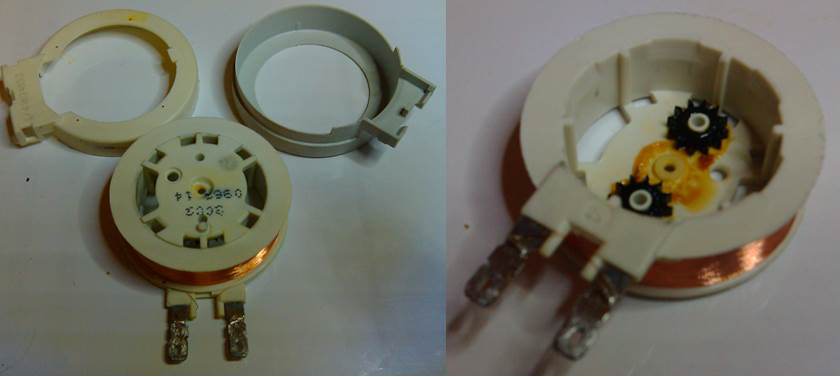

- We continue disassembling the programmer. Now our task is to remove all the gears one by one, and then the programmer motor core.

- Next, visually inspect the integrity of all components, wipe the contacts with alcohol, and reassemble the device in reverse order. The repair of this control element is complete.

Please note! When disassembling the programmer motor, be sure to inspect the winding, as it can also burn out, which will impair the control device's operation. If you find a burnt wire, you'll need to remove it and wind a new one in its place.

Experts strongly advise against attempting to repair German washing machine programmers yourself. Miele or Siemens. Their devices have a complex design consisting of several plates pressed together in pairs. When you try to disassemble these programmers, the plates fly apart, making it extremely difficult to reassemble them, as the plates shatter and damage the fragile plastic grooves. We, for our part, recommend entrusting repairs to German washing machine programmers to qualified technicians.

It should be noted that German programmers are not the most difficult. In washing machines Gorenie, programmers with a soldered control board are installed. Repairing them requires masterful soldering skills—not just a regular soldering iron, but a special one with a fine tip. Even most repairmen won't attempt to repair these types of programmers, so we recommend that you don't waste your time and simply replace your broken Gorenie washing machine programmer with a new one.

In conclusion, it's worth noting that repairing an automatic transmission's control unit yourself isn't always a rewarding endeavor. Some units have very simple designs, and a bit of tinkering isn't a bad idea. While it might not work, it won't make things worse. Other control units, however, are so complex that repairing them is simply impractical, or should only be attempted by a qualified technician.

Interesting:

16 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

I found out what I was interested in. THANK YOU.

I can't turn off the program; it just keeps running. What should I do?

Thanks for the warning.

Hello! My washing machine isn't heating the water. The heating element and sensor are working properly. What else could it be?

Pressure switch, control module (heating element relay).

Hello! My Candy washing machine works as expected in the short wash cycle, but in other cycles, the heating element might not turn on or some other malfunction might occur. It fills and drains water as expected, and the spin cycle works as expected. I'm blaming the programmer.

The Indesit washing machine does not switch from rinsing to spinning; it spins all the time until you turn it off yourself.

The programmer knob rotates freely, as if it has slipped. What should I do?

I have an Ariston AVD 109 washing machine, and the programmator button fell off. Can you tell me how to put it back?

Could someone send me some photos of the wiring connections for the control unit of a Bosch wfb 2005 washing machine?

Could someone send photos of the wiring connections for the control unit of the Bosch WFB1070 BY/07FD 7510 washing machine? Thank you.

Hello, my Indesit 4085 washing machine won't switch to rinse mode after washing. It just keeps filling with water until I switch it to manual mode. Does anyone know what to do?

Is it possible to make a programmer for the Ardo A1000x car myself? My child turned it backwards. Now, when I turn it on, the indicator light comes on, but nothing else works. Even the doors won't lock.

I have an Ariston washing machine. It turns on and fills with water. After two spins, the drain and super wash indicators turn on, and the water drains. I blame the programmer.

Hello, my Indesit machine washed, rinsed, and drained. During the second rinse, it turned the water on and off. This happened three times. Then, an error message appeared. I checked everything, and water was coming in. I was only able to change the mode after unplugging it. Now, when I set it to spin, the drum doesn't spin. Eventually, only the drain works. What's wrong?

When assembling the programmer, do the slow cams need to be set in any direction?