How to fix a washing machine programmer

The dashboard of automatic washing machines features a program selector knob. It allows users to select the desired washing algorithms. This complex mechanism is responsible for activating various modes, including spinning, draining, and rinsing.

The dashboard of automatic washing machines features a program selector knob. It allows users to select the desired washing algorithms. This complex mechanism is responsible for activating various modes, including spinning, draining, and rinsing.

If the selector switch breaks, using the machine becomes impossible. In most cases, you can repair a washing machine's programmer switch yourself. We'll explain the components of the device and how to fix it.

What parts does the programmer consist of?

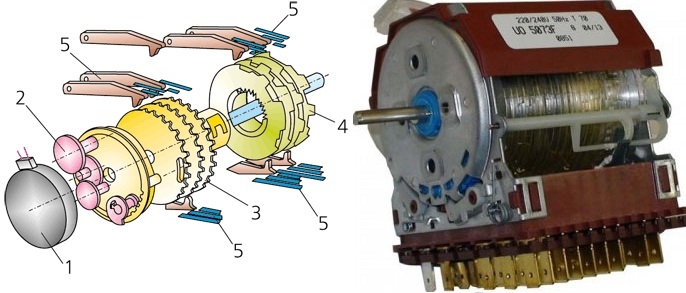

If you decide to repair the program selector yourself, you need to determine what parts the device is made of. The mechanism includes the following elements:

- motor;

- fee;

- contacts;

- gears;

- gearbox;

- cams (these are special protrusions and recesses that activate the synchromotor).

On modern automatic machines you can find two types of programmers: mechanical or electronic.

Mechanical (hybrid) program selectors are considered the most reliable; they break down extremely rarely. If necessary, they are easier and cheaper to repair. Electronic components are more modern, but they fail more often because they are sensitive to fluctuations in the power supply.

We are repairing the part

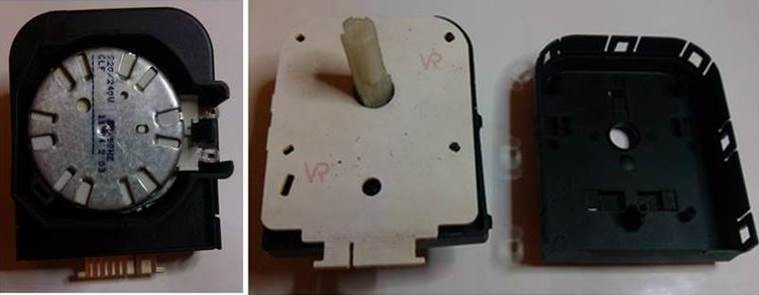

First, you need to remove the programmer and then disassemble it. The main difficulty is that there are many types of selectors, even on machines of the same brand, they differ. And each device has its own unique characteristics.

We'll explain how to disassemble an Ariston washing machine programmer. The procedure is as follows:

- de-energize the washing machine;

- remove the control unit from the dashboard, having dealt with the fasteners;

- Find the clips that hold the back of the device in place;

- Pry up the latches and remove the programmer housing cover. Proceed carefully, as there are small springs hidden underneath that could break loose and become lost.

- carefully remove the board “hidden” under the programmer cover;

- remove the largest gear located in the center;

- Check to see if any debris has clogged the small gears. Often, clogged gears are the cause of programmer failure;

- Inspect the board for any traces of carbon deposits. If the semiconductors or tracks are damaged, you'll need to use a soldering iron.

It happens that there is no visible damage inside the selector. You can check the functionality of the washing machine programmer using a multimeter. Place the probes on the board contacts and measure the resistance between them.

If the readings are normal, you need to disassemble the device further. Follow these steps:

- remove all gears;

- remove the selector motor core;

- assess whether there are any defects on the extracted elements;

- wipe the contacts of the parts with alcohol;

- put the programmer back together.

When disassembling the sync motor, be sure to inspect the motor winding - it may burn out or break.

Owners of Miele or Siemens washing machines are advised not to attempt repairs themselves. The programmers on German washing machines are very complex, consisting of several plates pressed together in pairs. These plates shatter during disassembly, making it difficult to repair. In this case, it's best to entrust the job to a service center.

But even German programmers are considered a mere trifle compared to the devices found in Scandinavian washing machines from Gorenje and Asko. Manufacturers install selectors with a soldered-in control board. Only a skilled technician with a fine-toothed soldering iron can repair them.

Specialists almost never repair program selectors on Gorenje and Asko machines. Therefore, in this case, it's better to purchase and install a working programmer. When choosing a device, consider the model of your washing machine.

Why does the part break?

It's quite easy to determine if the programmer is faulty. If you turn the selector knob and the machine doesn't switch between wash modes, the device is faulty.. Other signs may also indicate a breakdown:

- The washing machine won't turn on. There could be several possible causes, but if there are no electrical issues, the problem is either with the control board or the programmer itself.

- during the washing process the algorithm gets confused, the duration of the cycle increases or decreases;

- After turning on the machine, the indicator on the dashboard flashes randomly.

Mechanical control units are very reliable. They typically operate without interruption for the entire life of the automated machine: 10 or even 20 years. The main reason for the breakdown of hybrid programmers is considered to be careless handling of washing equipment. For example, if you twist and pull the handle with force in different directions, it can easily be damaged.

The main cause of electronic programmer failure is power surges. Moisture on the circuit board is also a common cause of malfunction. And, of course, manufacturing defects cannot be ruled out.

Most often, you can repair the programmer yourself. This applies to devices installed in Samsung, LG, Indesit, and Candy washing machines. Repair of control units in Miele and Siemens machines is best left to specialists. And it's best to replace the selector switches in Swedish and Slovenian Gorenje and Asko machines with new ones right away.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment