Asko Washing Machine Repair

Professional washing machine repairs rarely involve Asko washing machines. In Russia, they are much less common than Indesit, Samsung, LG, and other well-known brands. Repairing Asko washing machines, as well as their breakdowns, have their own specifics. These breakdowns will be the subject of our discussion.

Professional washing machine repairs rarely involve Asko washing machines. In Russia, they are much less common than Indesit, Samsung, LG, and other well-known brands. Repairing Asko washing machines, as well as their breakdowns, have their own specifics. These breakdowns will be the subject of our discussion.

The most typical breakdowns

As mentioned above, there aren't many Asko washing machines in Russia; however, they break down quite frequently. Owners of this brand's washing machines contact service centers across the country with roughly the same problems:

- the drum does not spin or spins too slowly;

- the hatch either does not close at all or does not lock;

- washing takes place in cold water, the water is not heated in any washing program;

- Asko washing machine refuses to drain waste water and freezes.

The situation with Asko washing machines is quite surprising. It's a well-known fact that in Finland, nearly a quarter of all families use these automatic washing machines and are very satisfied. Based on statistics from their service centers, Asko washing machines can easily be compared to German-made Miele or AEG. In Russia and the CIS, the situation is quite the opposite, as Asko washing machines break down more often than other machines.

The situation with Asko washing machines is quite surprising. It's a well-known fact that in Finland, nearly a quarter of all families use these automatic washing machines and are very satisfied. Based on statistics from their service centers, Asko washing machines can easily be compared to German-made Miele or AEG. In Russia and the CIS, the situation is quite the opposite, as Asko washing machines break down more often than other machines.

For example, in Zelenodolsk, there are only seven Asko washing machines, if we believe the data from their service centers. And all of these machines have been repaired multiple times with the same problems: the hatch, the heating element, the motor, the pump, and the hoses. The quality of the parts is appalling, and the assembly doesn't resemble European standards. So, we wondered about the true origins of Asko washing machines, but we couldn't find any reliable information, so we return to our main question: the typical problems with this brand of washing machines.

FYI! Got a Finnish or Swedish-made Asko washing machine? Consider yourself lucky: even used Asko appliances that have been in use in Europe for 10 years or more often last another 15-20 years for their subsequent owners.

The drum does not rotate

Asko washing machine repairs are most often required when the motor doesn't rotate the drum properly or refuses to rotate it at all. It would be a little easier to diagnose the problem and repair the machine yourself if the self-diagnostic system always worked. As it is, the drum doesn't rotate and no errors appear.

What's the cause? The most common cause of this washing machine behavior is the drive belt. While it doesn't seem to slip, it's slipping along the motor pulley and can't rotate the drum pulley properly. As a result, the drum either stops under load or rotates extremely slowly, at 100-150 rpm. At this speed, washing and rinsing are impossible, let alone spinning.

If you dig deeper, it's not even the belt itself, since it might be intact, except for the wear. The problem is the engine pulley. How do I replace it?

Perhaps a low-quality pulley was installed at the factory, or perhaps it gets damaged during operation, but the fact remains - the pulley damages the drive belt and needs to be replaced!

- We remove the back wall of the Asko washing machine with our own hands.

- We pull the drive belt off the pulleys and inspect it.

- We inspect the engine pulley; if any defects are detected, we continue working in this direction.

- We remove the wires from the engine and unscrew it.

- We take a household bearing puller and a blowtorch and go outside, since it is better not to carry out this kind of work inside the house.

- Place the puller on the engine pulley and apply strong tension. Don't try to pull the pulley off right away; firstly, it won't work, and secondly, you'll break the puller.

- Light the blowtorch, wait for it to heat up, and then carefully begin heating the engine pulley. Be careful to heat only the pulley and avoid touching other metal components.

- Once heated, the pulley should come off with virtually no assistance.

- Next, you cool the pulley, go to the store, and buy the same part. If the store doesn't have it, you can order it online.

- We also install the new pulley while it is hot, having previously heated it to red heat with a blowtorch.

- After the new pulley is seated, let it cool and reinstall the engine and belt. It's best to replace the belt as well.

- We install the back wall, and then connect and test the updated washing machine.

Be careful! If your washing machine displays the E01 error code, the problem lies either with the motor itself or the control board. In this case, it's best to contact a specialist.

Does not block the hatch

Quite often, Asko washing machines have to be repaired by hand due to a drum door that refuses to close. It all starts when the door mechanism occasionally stops working, causing the machine to freeze when starting. Typically, homeowners quickly find a solution by pushing the door with their knee and restarting the Asko machine. After that, the machine washes normally for a while. Then, after a year or two, or maybe even less, the door mechanism stops working altogether, and the machine consequently stops washing.

Quite often, Asko washing machines have to be repaired by hand due to a drum door that refuses to close. It all starts when the door mechanism occasionally stops working, causing the machine to freeze when starting. Typically, homeowners quickly find a solution by pushing the door with their knee and restarting the Asko machine. After that, the machine washes normally for a while. Then, after a year or two, or maybe even less, the door mechanism stops working altogether, and the machine consequently stops washing.

In this situation, "nudging with your knee" no longer helps; you have to disassemble the hatch closing mechanism and replace the locking device. Here's what to do if the washing machine door won't close, and how to fix it, read in the publication of the same name.

Washes in cold water

Asko washing machines experience heating problems slightly less frequently. In most cases, the problem can be quickly identified, as the self-diagnostic system triggers when it occurs, displaying error code E05. Less commonly, error code E06 appears. What causes these errors?

- The temperature sensor is not working.

- There is no contact between the control module and the temperature sensor.

- The board's triac, responsible for controlling the heating element, has failed.

- The heating element broke.

Which of these components is broken in your Asko washing machine remains to be determined. Let's start by diagnosing the heating element and temperature sensor. But before diagnosing these components, we need to get to them.

Important! Most automatic washing machines have a heating element with a temperature sensor located either at the rear or front of the drum. Asko washing machines have a heating element embedded in the side of the drum.

With such an unusual placement of the heating element, how do we get to it? It's not difficult: remove the back panel of the washing machine, move the drive belt out of the way, and there you have it, the heating element—or rather, its contacts protruding from the side of the drum. What do we do?

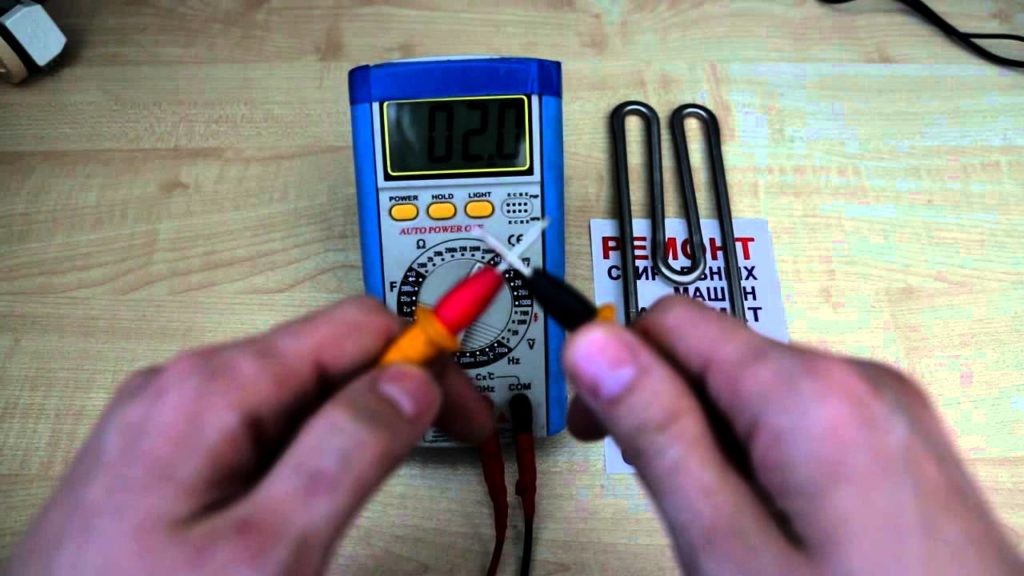

- We take a multimeter and set the switch to the minimum value.

- We disconnect the wires from the contacts of the heating element and the temperature sensor.

- We connect the multimeter probes to the heating element contacts. If the device display shows a resistance of around 28 Ohms (with a heating element power of 2 kW), then the heating element is working properly. If it shows zero or one, it is faulty.

- Now let's check the resistance of the temperature sensor. Disconnect the drain hose from the tank and drain any remaining water into a suitable container.

Please note: When draining the tank, be careful not to spill water on the contacts, wiring, or motor, otherwise you'll have to dry them all with a hair dryer.

- We pull the temperature sensor out of the connector and put it aside.

- We fill a mug with warm water (300) and lower the temperature sensor there.

- After a couple of minutes, remove it, set the multimeter to the minimum resistance value, and touch the probes to the sensor contacts. If the device reads 40-60 ohms, everything is fine; 0-1 ohm indicates something is wrong.

Next, you can check the wires running from the heating element and temperature sensor to the control module yourself by testing them one by one. If the wires are intact, all that's left is the control module. We don't recommend accessing the control board yourself, as if it's damaged, repairs will be very expensive. Contact experienced technicians.

It doesn't drain water.

If your Asko automatic washing machine stops draining and freezes, but the inside of the machine is dry, one of the following problems may have occurred:

- the pipes or drain hose are clogged;

- the pump broke;

- the water level sensor does not work;

- There is a break between the control board and the pump or between the control board and the level sensor.

Before looking for the cause of the problem in the electrical and electronic components, let's give the Asko washing machine a thorough cleaning. Cleaning the washing machineIt will take some effort to remove the dirt, but after that, normal water drainage can resume, and your “home helper” will smell very nice.

Before looking for the cause of the problem in the electrical and electronic components, let's give the Asko washing machine a thorough cleaning. Cleaning the washing machineIt will take some effort to remove the dirt, but after that, normal water drainage can resume, and your “home helper” will smell very nice.

If cleaning doesn't solve the problem, you'll need to use a multimeter and check the pump, water level sensor, and electrical system for any faults. First, test the pump; its operating resistance is 144 ohms. Next, test the water level sensor; its resistance should be around 60 ohms. Finally, test the wires leading to the control module for open circuits. If there are no open circuits, the problem lies with the microcircuit and you should contact a specialist.

Please note: The pump and water level sensor are accessible through the rear wall of the washing machine.

In conclusion, I'd like to emphasize one more point. Most washing machine problems can be fixed yourself if you carefully read the service manuals and the information we publish in our articles. However, if the problem is electronic, it's best not to attempt the repair yourself. Even a specialist who resolders the circuit board doesn't guarantee it will work. Don't let your washing machine fail; trust the professionals!

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment