Repairing the water inlet valve in a washing machine

A faulty inlet valve can be indicated by various symptoms. These include a lack of water or a slow water intake, a puddle under the machine, or poor detergent intake from the dispenser. Let's look at how to check and, if necessary, repair or replace the element yourself.

A faulty inlet valve can be indicated by various symptoms. These include a lack of water or a slow water intake, a puddle under the machine, or poor detergent intake from the dispenser. Let's look at how to check and, if necessary, repair or replace the element yourself.

Getting ready to repair the valve

There are many signs that your washing machine's inlet valve needs repair. As mentioned above, these include a puddle forming under the machine immediately after starting a cycle, the tank filling up when the machine is turned off, and, conversely, no water flow while the machine is running.

You can check for a faulty washing machine inlet valve using a multimeter.

Before troubleshooting, be sure to take basic safety precautions: turn off the power to the washing machine and turn off the shutoff valve. Have a shallow basin and dry rags ready to collect any spilled water.

After unplugging the machine, move it away from the wall and drain any remaining water from the system through the waste filter. It's located at the bottom of the machine, in the right corner behind the decorative panel or service door. Place a basin under the machine, remove the waste filter cap, and collect the water in the container. Then rinse the filter element and replace it.

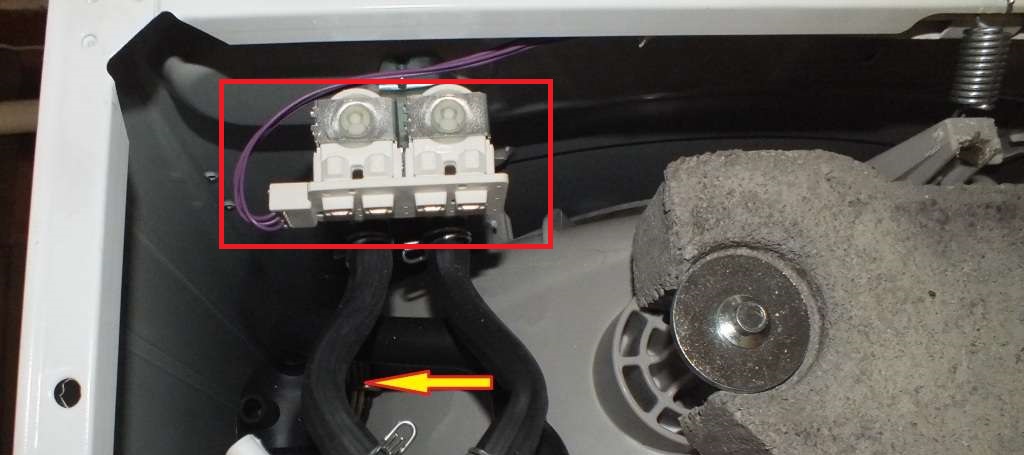

The water inlet valve is located just under the top cover of the washing machine. Remove the panel by unscrewing the two screws that secure it. Next, you need to remove the component itself from the housing. During diagnostics and repair, you will need:

- Phillips and slotted screwdrivers;

- pliers;

- pliers with sharp tips;

- multimeter.

Removing the intake valve is very simple. Simply disconnect the wiring and remove the screws holding it in place. We'll explain the components and how it works.

How does this element work?

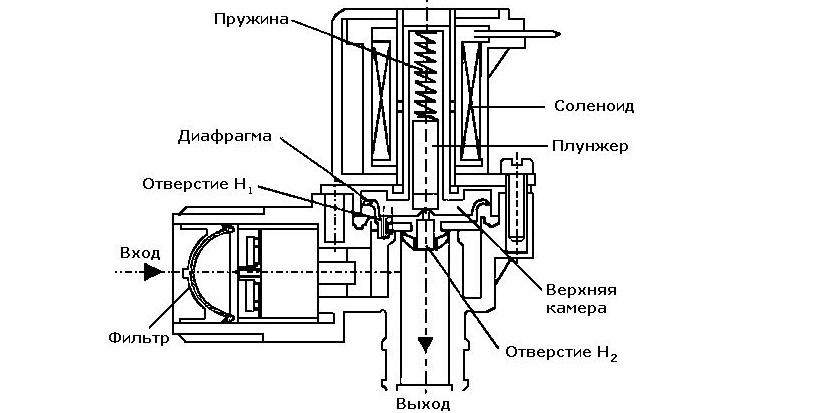

The shutoff valve in an automatic washing machine functions like a regular faucet. However, it's opened and closed not manually, but by a signal from the control module. When voltage is applied to the inlet valve, the coil is activated, pulling the rod in, thereby ensuring the flow of water through the powder receptacle into the washing machine tank. The water supply valve consists of:

- housings;

- magnetic coil (there may be several of them, it depends on the type of device);

- rod;

- metal spring;

- membranes;

- mesh filters;

- inserts into fittings;

- sealing gasket;

- fasteners.

When the user starts a washing program, the control module transmits voltage to the coil. Sensing the impulses, it pulls the rod. This opens the polyurethane membrane, and water from the pipes begins to flow under high pressure into the washing machine. When the drum is filled to the required level, the pressure switch signals this, and the machine's "brain" cuts off the current. The spring returns, and the inlet valve closes.

What happened to the inlet valve?

There may be several reasons why a valve stops functioning properly. To repair the element and restore the machine's functionality, you'll need to determine what's wrong with the device. We'll cover the main types of malfunctions that can occur.

- Clogged filter. Immediately after the inlet hose, at the valve inlet, there's a mesh strainer that traps various impurities found in tap water. Over time, it becomes clogged and begins to restrict water flow. The strainer can be removed without disassembling the machine. Simply grab the mesh strainer with pliers and pull it toward you. After rinsing, replace the filter.

- Diaphragm contamination. The elastic seal moves up and down with each stroke of the piston rod. If it becomes dirty, it begins to loosen against the valve seat and leak water. To inspect the seal, you'll have to disassemble the intake manifold. If there's rust on the surface, clean it off; if there are cracks, replace the gasket.

- Spring problems. Over time, the mechanism may break, and the rod will no longer move up and down freely. Therefore, if the metal spring is broken or deformed, it will need to be replaced.

- Cracks in the appliance body. The valve usually has a plastic "shell" that can become damaged. If this happens, some water will leak out of the inlet element, contacting the electrical components of the machine. This can cause the washing machine to generate an electric shock, which can lead to a short circuit. In this case, the part must be replaced as soon as possible.

The plastic valve body often cracks in machines stored in cold rooms. At subzero temperatures, water freezes and expands the valve body. The elastic membrane can no longer hold liquid after such a freeze. Therefore, if your washing machine starts leaking after winter, the inlet valve needs to be replaced.

Once the water inlet valve has been removed from the housing, it should be carefully inspected. If you notice that the electromagnetic coils are deformed, replace the element immediately; in this case, there is no point in repairing it. We'll tell you how to diagnose a part.

Testing the valve

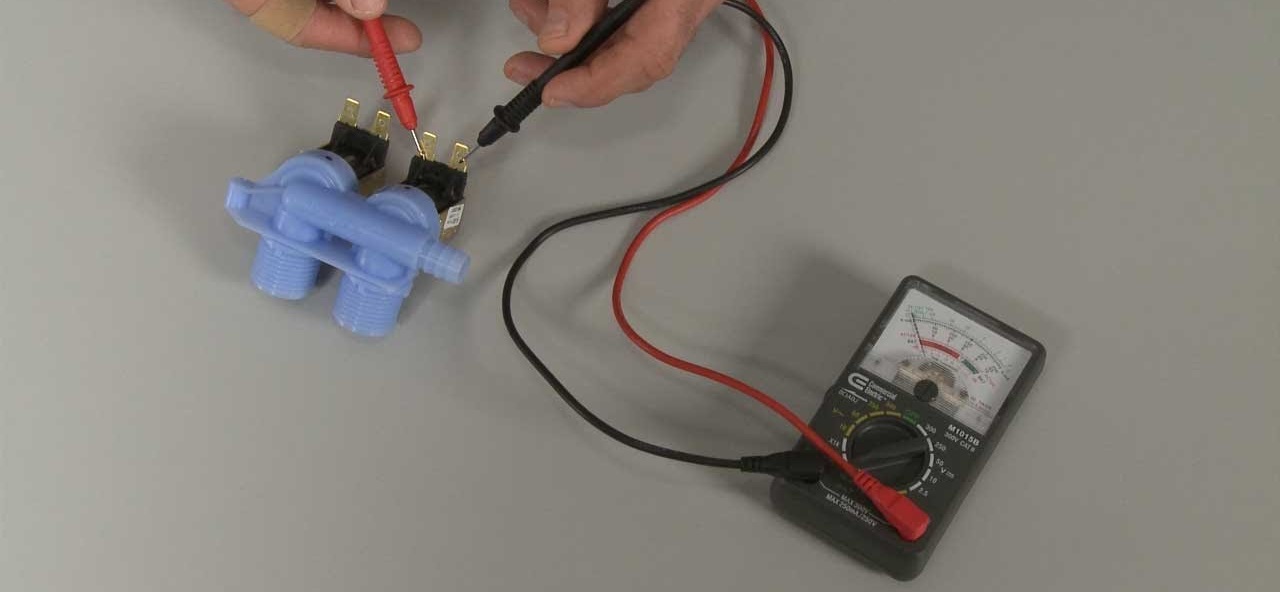

The inlet valve's functionality depends largely on the solenoid coil. It "activates" the piston rod, allowing water to enter the system. There are two ways to test it. The first, and easiest, is with a multimeter. Set the tester to resistance mode and place its probes on the coil's contacts. If the water inlet valve is working properly, the device's screen will display a value between 2000 and 4000 ohms.

If the inlet valve on your automatic washing machine is of the double or triple type, you need to test each coil separately with a multimeter.

The second method is to apply 220V to the coil. If it's working properly, a magnetic field will be created and the rod will be pulled upward (you'll hear a characteristic clicking sound). When the power is turned off, everything will return to normal. This method requires extreme caution, so it's best to use a multimeter.

We disassemble and repair the valve

As mentioned earlier, the valve is located under the top panel of the machine, in the left corner. To repair or replace the element, it must be removed from the housing. Therefore, you need to unscrew the two screws holding the washing machine's "lid." Next, disconnect the wiring from the water inlet valve. Before removing the terminals, it's a good idea to photograph the wiring diagram. This will help you avoid mistakes during reassembly. Disassembling the element is as follows:

- remove the coils by prying them from below with a slotted screwdriver;

- Use pliers to carefully pull out the rods. If the parts don't budge, spray them with WD-40 and try again.

- remove the metal rod with the membrane and spring.

The solenoid valve is disassembled – now it's time to carefully inspect each component for defects, deposits, rust, and blockages. Clean all components and reassemble in reverse order. If any components are broken or deformed, replace them yourself. For example, install a new membrane or spring. Some difficulties may arise with the selection of spare parts, but they can always be ordered online.

If you discover a fault that can't be repaired, it's best to purchase and install a new inlet valve. For example, if you notice that the solenoid coil is deformed, it's not worth saving money and risking the health of the machine's control module.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment