Homemade washing machine

People living in bustling cities often go to their dachas (country houses) for vacations or weekends. And such a pleasant vacation can be ruined by, for example, a broken washing machine. This means having to travel dozens of kilometers back to the city, buy a new one, and arrange for its delivery. Not everyone knows that you can build a homemade washing machine from household items. This way, you can solve this problem without wasting energy on grueling trips or money on purchasing equipment. Let's figure out how to build a washing machine yourself.

People living in bustling cities often go to their dachas (country houses) for vacations or weekends. And such a pleasant vacation can be ruined by, for example, a broken washing machine. This means having to travel dozens of kilometers back to the city, buy a new one, and arrange for its delivery. Not everyone knows that you can build a homemade washing machine from household items. This way, you can solve this problem without wasting energy on grueling trips or money on purchasing equipment. Let's figure out how to build a washing machine yourself.

How and from what is it more profitable to make it?

Trying to make things easier, the first thing you'll try is to repair the broken equipment. While this is the right thing to do, in most cases you'll still have to make a trip to the store to purchase replacement parts. If you had a activator washing machine like "Baby", then repairing it is too tedious and not economically feasible.

What if there is no way to get to the city? You can assemble a washing machine yourself from parts lying around in a garden shed, taking some elements from equipment that has served its purpose. Ideally, the designed product should eliminate the need for welding and turning. Assembly will take several hours.

Assembling the washing machine

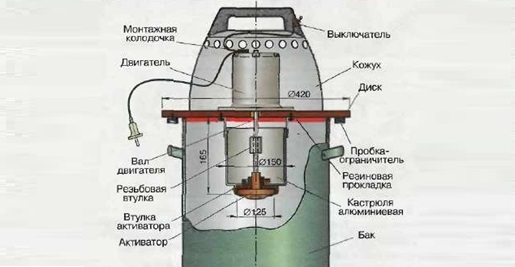

Before assembling a washing machine yourself, you need to understand the scope of the work ahead. It's important to determine whether you can find the necessary parts and components on your property. The washing machine's design looks like this:

For example, you can use the electric motor from a "Skilled Hands" machine as a drive. A large enamel saucepan can serve as a tank. The activator and its bushing must be removed from the broken washing machine.

You should make your own device that will power the washing process. To do this, take a plastic disk, approximately 8 mm thick, with a diameter 10 cm larger than the circumference of the container used as the drum. Drill a 1 cm diameter hole in the center of this prepared disk, into which the motor shaft will be inserted. The electric motor is secured to the disk with stator bolts; their dimensions are ideal for this application.

It is advisable to place a rubber gasket between the disc and the engine.

Next, it's time to work on the activator. Take a saucepan of a suitable size and drill a hole in its bottom. Insert the activator sleeve into the hole and tighten it with a nut from the inside. The activator shaft is placed inside the sleeve from the outside.

Next, you need to connect the actuator to the electric motor. The motor shaft has a 10 mm thread at the end. The standard actuator also comes with a 1 cm threaded axle. If you don't have a ready-made bushing of the same size at your dacha to connect the two axles, you can do the following: Take an M10 bolt and three M10 nuts and screw them onto it. Slide a steel tube of the appropriate diameter onto the resulting assembly and crimp its ends. By bending the tube off the bolt, you'll have a secure bushing of the required size. The homemade sleeve must be screwed halfway onto the electric motor shaft, and the other end onto the activator axle.

So, the DIY washing machine is almost ready. It has a tub for filling with water and loading laundry, as well as a working unit that initiates the wash cycle. The motor, which is essentially located on the outside, should be covered, perhaps with a section of an old vacuum cleaner housing. The protective cover is attached using special tabs.

It's important to connect the wiring to the motor correctly. The wire connections will be located under the cover. The power cable is also recessed under the cover, leaving only a small portion with the plug exposed.

To ensure the disk stays in place while the machine is in operation, screw six caps from regular plastic bottles to its bottom. This will prevent the lid from shifting off-center while the homemade washing machine is in operation. It's also a good idea to rubberize the top of the tank—an enamel pot in the example described. A rubber tube works well for this purpose. Cut it in half lengthwise and carefully place each half over the edges of the container.

How does the machine function?

The washing process is as follows: The laundry is placed in the drum, along with washing powder or liquid detergent. Then, the items are filled with water at the desired temperature.

The amount of water and clothing that an electric motor can pull is calculated empirically.

The device is immersed in the tank. The plugs on the underside of the disk are positioned around the outside of the tank. The motor is then started. No additional securing of the operating system to the tank is required. The electric motor shaft speed will be high, which will ensure high quality washing of the laundry.

A significant drawback of a homemade washing machine in this case is its low productivity. Due to the modest motor power and small drum capacity, it can only wash about 1 kg of dry laundry at a time, equivalent to, say, five men's shirts. Loading more items will significantly reduce cleaning performance. To increase the washing machine's productivity, you can look for a more powerful motor and a larger drum capacity.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment