What wire gauge is needed for a dishwasher?

When planning a major kitchen renovation, consider in advance what appliances you'll be installing. While regular outlets will suffice for a kettle, microwave, and refrigerator, a separate power point will be necessary for an electric stove or dishwasher. Let's explore the required cable cross-section for a dishwasher, why a dedicated line is needed, and how to properly route the wiring.

When planning a major kitchen renovation, consider in advance what appliances you'll be installing. While regular outlets will suffice for a kettle, microwave, and refrigerator, a separate power point will be necessary for an electric stove or dishwasher. Let's explore the required cable cross-section for a dishwasher, why a dedicated line is needed, and how to properly route the wiring.

Why draw a separate line?

Why is it important to consider the placement of furniture and appliances in a room even during the renovation stage? So, for the dishwasher, it is necessary to provide a separate power supply line, and a protected one, coming not from the distribution box, but directly from the panel. This is the only way to ensure maximum safety when using the machine.

In general, the dishwasher is prohibited:

- connect via an extension cord;

- connect to a socket where another powerful power consumer is already connected;

- connect to a weak, damaged outlet.

A dishwasher is a large consumer of electrical energy, creating a large load on the network.

This is why it's important to provide a dedicated line for the dishwasher. The cable will experience the greatest stress when the high-temperature cycle starts. If it's too small, it can easily overheat and cause a fire or damage the appliance.

Therefore, the dishwasher's cable cross-section must be adequate for the appliance's power consumption. The cable is routed from the electrical panel, and a residual-current device (RCD) is required. The dishwasher's socket must have a high level of moisture protection. Only by meeting all these requirements can the dishwasher be safely operated.

If you plan to install both a dishwasher and a washing machine in the kitchen, it's not necessary to install two lines. In this case, select a large-gauge copper cable (to provide extra power) and power a second moisture-resistant outlet from it.

Which cable should I choose?

After considering where the dishwasher will be installed and where the separate power line will run, it's important to determine the cable's cross-section, material, and number of conductors. Experts recommend not skimping on copper wire, as aluminum cords are not suitable for connecting large loads.

So, the cable must be copper, but how many strands does it have? By modern standards, all dishwashers must have a grounded power cord, so a grounded outlet will be required for the appliance. This means the cable must be three-wire, with "live," "neutral," and "ground" terminals.

Next, you need to calculate the cable cross-section for the dishwasher. The average power of most modern dishwashers is 1.5 to 2 kilowatts. The exact value can be found in the appliance's manual. As mentioned earlier, the cord should be selected with some allowance. Therefore, its thickness can be as small as 2.5 mm.

To organize a separate power line for the dishwasher, you need to buy a three-core copper cable with a cross-section of 2.5 mm.

The copper wire must have good insulation. To install the electrical line, you'll also need to purchase:

- a socket with a high level of moisture protection;

- residual current circuit breaker;

- socket box;

- copper terminals;

- cable channel.

The outlet must be moisture-resistant, as the dishwasher handles a large amount of liquid. This protection will prevent short circuits in the event of a leak.

A residual-current circuit breaker (RCD) will provide protection against power surges. An RCD will trip in the event of sudden voltage fluctuations in the electrical network. This will protect your equipment and prevent premature failure.

Copper terminals will be required for connecting cables. If possible, it's best to avoid splices and install a single piece of wire. Never connect copper and aluminum wires together—such a cost-cutting measure could not only damage all appliances powered by the power grid but also cause a fire in the room.

Skimping on the wall box is also not a good idea – it must be high-quality. Cheap plastic parts can melt under heavy loads and cause a fire. Experts recommend using junction boxes from reputable and trusted manufacturers.

The cable channel should be made of high-quality plastic. It will hold the wires and provide additional protection for the wiring.

Laying communications

At the initial stage, plan how the separate power line for the dishwasher will be routed. Consider the best outlet location. Consider not only the outlet's height but also its distance from the electrical panel.

The further the socket is from the electrical panel, the more you will have to spend on components.

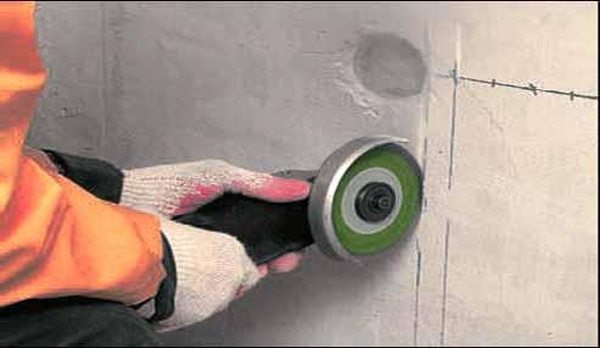

Therefore, it's worth considering the optimal cable routing route. The closer the outlet is to the electrical panel, the less chasing will be required, which is a very labor-intensive job. You can draw a wiring diagram directly on the wall with a marker, also marking the location for drilling a hole for the electrical box.

Once you've mapped out your wiring plan, you can measure how much cable you'll need. It's best to buy a little extra cable, allowing for any potential errors in your calculations.

Next, you can begin cutting grooves. The procedure will depend on the material the walls are made of. For example:

- "soft" walls, such as wooden or plasterboard, can be cut using a hammer and chisel;

- Reinforced concrete walls are drilled with a hammer drill. First, holes are made along the future gutter, then they are connected with a chisel and hammer. Any rebar that gets in the way will need to be partially removed with a grinder.

The cable runs from the electrical panel to the outlet. It's important to mark in advance where the terminals will be connected later—neutral, live, and ground. There's no need to connect the wires here right away.

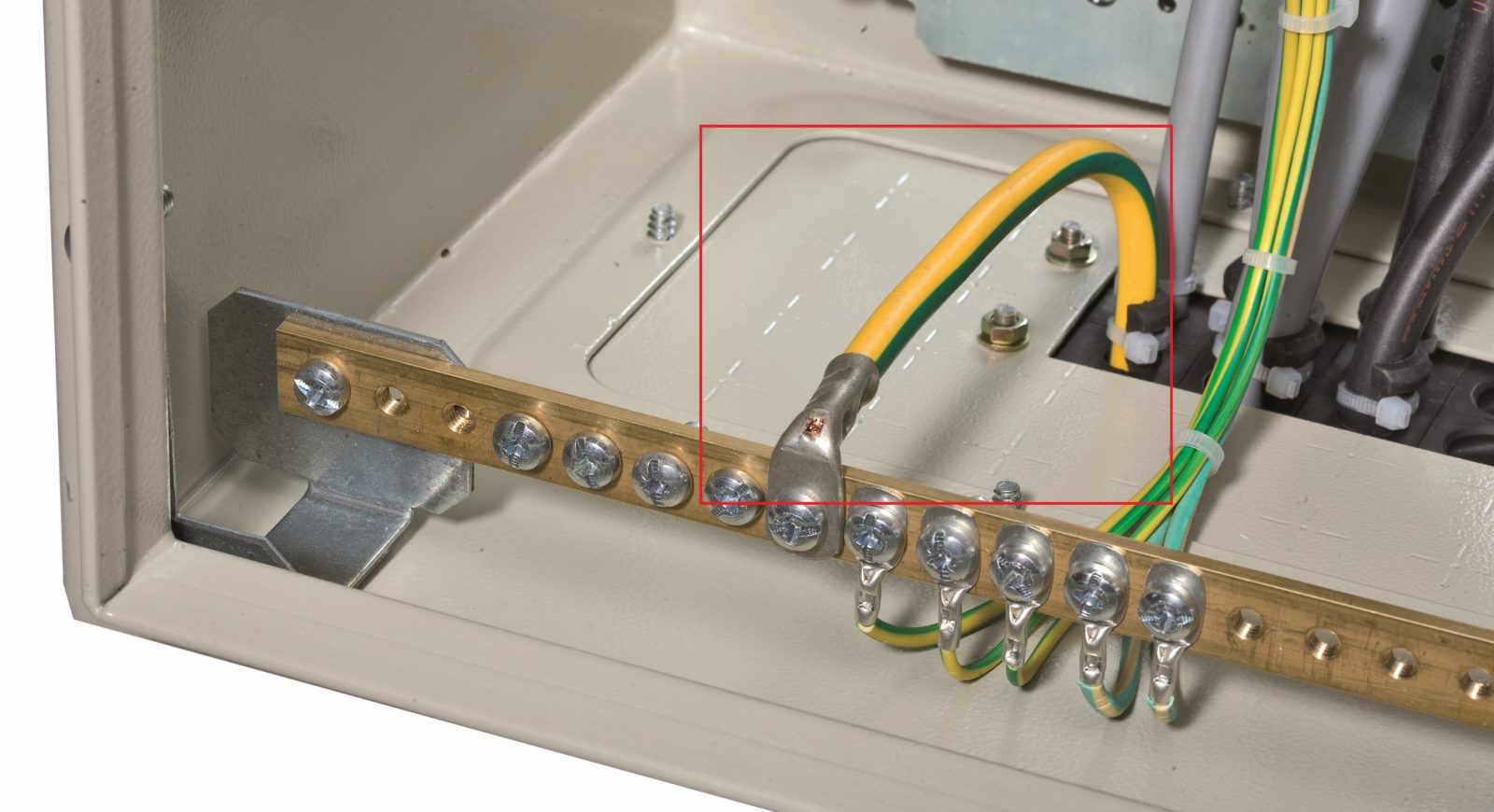

A residual-current circuit breaker (RCD) is installed in the distribution board. The neutral and phase wires are routed through the RCD. The ground is connected separately. Basic safety precautions and personal protective equipment must be observed during work.

The connection points must be carefully insulated.

Plastic cable conduit is installed into the grooves created. The wiring is routed from the electrical panel and laid in the resulting recess. Once the copper cable is finished, leave it alone and proceed with installing the outlet.

The socket is installed as follows:

- a hole is made for the socket box using a hammer drill (there are special attachments for straight drilling on sale);

- the socket box is “sat” into the recess using sealant;

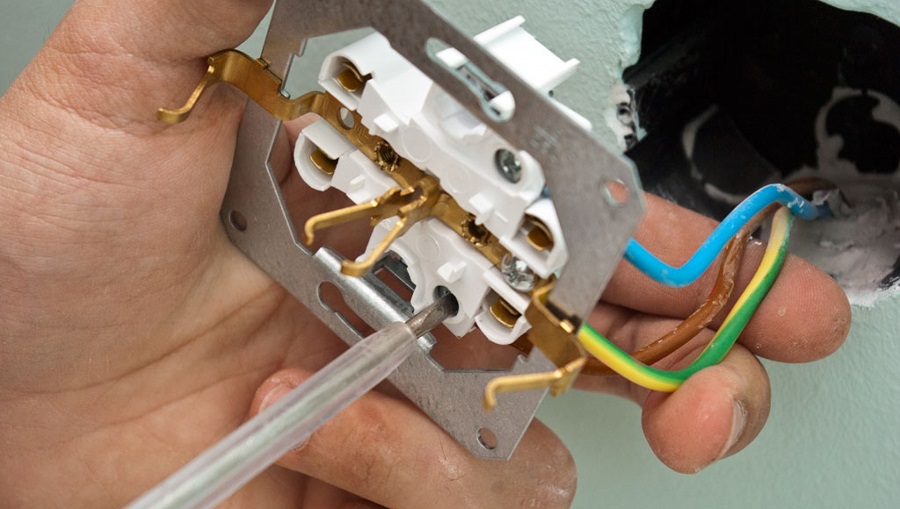

- the ends of the cable are fed into the socket box;

- the socket itself is unpacked and its “guts” are taken out;

- the corresponding cable cores are connected to the socket contacts;

- the base of the socket is fixed in place (it should fit tightly and not wobble);

- The plastic socket housing is screwed on.

After this, return to the electrical panel and connect the live, neutral, and ground wires to the appropriate contacts. Next, check to see if the outlet is working. To do this, connect a household appliance, such as a lamp or hair dryer, to it. You can also use a special indicator screwdriver. If everything is working properly, you can close the grooves in the wall.

The dishwasher's power lines should be taken care of in advance, even during the renovation phase. Such a large appliance will require a dedicated power line. The cable cross-section must be sufficient to handle the considerable load generated by the dishwasher. Be sure to protect the line with a residual-current circuit breaker to ensure the safety of the equipment and minimize the risk of short circuits.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment