Cable cross-section for a washing machine

When preparing for a major kitchen or bathroom renovation, it's crucial to plan ahead for the layout and location of electrical and other utilities. Even if you can't predict what appliances will be installed in these spaces, think ahead. If you're planning to install a washing machine in the bathroom or kitchen, consider installing a separate, appropriately sized wire for it. Why? We'll discuss this in this article.

When preparing for a major kitchen or bathroom renovation, it's crucial to plan ahead for the layout and location of electrical and other utilities. Even if you can't predict what appliances will be installed in these spaces, think ahead. If you're planning to install a washing machine in the bathroom or kitchen, consider installing a separate, appropriately sized wire for it. Why? We'll discuss this in this article.

Do you need a separate outlet?

First, let's answer a legitimate user question: why does an automatic washing machine need a separate, protected power line, which, moreover, runs not from the distribution box, but directly from the control panel? As we know, an automatic washing machine cannot:

- connect to the socket via an extension cord;

- connect to a socket to which a large consumer is already connected;

- connect to a weak outlet with unreliable wiring.

Why such restrictions? It's very simple: an automatic washing machine is a large consumer of electricity, creating a significant load on the electrical grid. The wire experiences the heaviest stress when the washing machine spins at high speeds. In such situations, the small aluminum wires in the outlet the washing machine is connected to overheat and can easily cause a fire.

Why such restrictions? It's very simple: an automatic washing machine is a large consumer of electricity, creating a significant load on the electrical grid. The wire experiences the heaviest stress when the washing machine spins at high speeds. In such situations, the small aluminum wires in the outlet the washing machine is connected to overheat and can easily cause a fire.

In this case, there's only one solution: while renovating the room where the washing machine will be located, install a separate, appropriately sized, wire made of suitable material directly from the electrical panel to a moisture-resistant outlet. This outlet will then power your washing machine. Otherwise, you risk a fire in your home or, at the very least, damaging your expensive appliance.

If you plan to connect a dishwasher in the same room, in addition to a washing machine, you don't need to install a separate line for it; simply use a large-gauge copper wire (with some extra) to power the second outlet.

Wiring and other components

First, you need to decide what kind of wire to use. Specifically, what cross-section will it have, how many strands will it have, and what material will it be made of? Let's start with the material. Experienced electricians advise against using aluminum wires for connecting large consumers, and in fact, they say that wires made of this material should only be used as a last resort. Therefore, the choice is limited—we'll go with copper wire.

First, you need to decide what kind of wire to use. Specifically, what cross-section will it have, how many strands will it have, and what material will it be made of? Let's start with the material. Experienced electricians advise against using aluminum wires for connecting large consumers, and in fact, they say that wires made of this material should only be used as a last resort. Therefore, the choice is limited—we'll go with copper wire.

Next, you need to determine the number of wires. According to technical regulations, any modern automatic washing machine has a grounded power cord, so we also need a grounded outlet for the washing machine. This means we simply need to take a wire with three wires: one wire is the phase, the second is neutral, and the third is ground.

Now we need to calculate the cross-section of this three-wire cable that will power the washing machine outlet. We could, of course, provide you with a table listing the cable cross-section, current, and power rating for a cable of the corresponding thickness, but we won't. Firstly, the average power of any modern automatic washing machine is 2500 kW. Secondly, we've already agreed that we'll use a cable with some reserve power, just in case anything happens in the future.

Therefore, based on our own findings and the opinions of reputable experts, we'll use a three-core copper wire (2.5 mm cross-section) with good insulation. In addition to the wire, we'll need:

- moisture-resistant socket;

- residual current circuit breaker;

- copper terminals and flush-mounted box;

- plastic cable channel.

A moisture-resistant outlet is essential because automatic washing machines are typically used in either the bathroom or kitchen, areas prone to dampness and moisture. The residual current circuit breaker will provide universal protection against failures that periodically occur in the imperfect Russian power system. Select a circuit breaker (RCD) for a washing machine The publication of the same name, located on the website, will help you. Copper terminals are needed to ensure reliable connections between electrical wiring components, but it's better to avoid connections altogether.

Never, ever, splice copper wires together with aluminum ones. Such cost-cutting will likely damage electrical appliances powered by the same circuit and could even cause a fire.

When installing an outlet that will bear a heavy load, use only the highest-quality electrical boxes. There have been cases where cheap plastic electrical boxes have caused fires. It's also best to use the highest-quality plastic conduit.

When installing an outlet that will bear a heavy load, use only the highest-quality electrical boxes. There have been cases where cheap plastic electrical boxes have caused fires. It's also best to use the highest-quality plastic conduit.

Some electricians see nothing wrong with running cable directly into a channel cut into the wall, as it's insulated. In our opinion, it's better to additionally protect the cable with a conduit. You never know what might happen, since the electrical system will be in operation for decades.

We are pulling electrical communications

Before running and connecting the cable, it's important to determine the best location for the outlet. It's important to consider not only the outlet's height but also its distance from the distribution board. It's important to understand that the further the outlet is from the panel, the higher the cost of components and the more wall chasing you'll have to do to accommodate the wiring, and chasing is a very labor-intensive job.

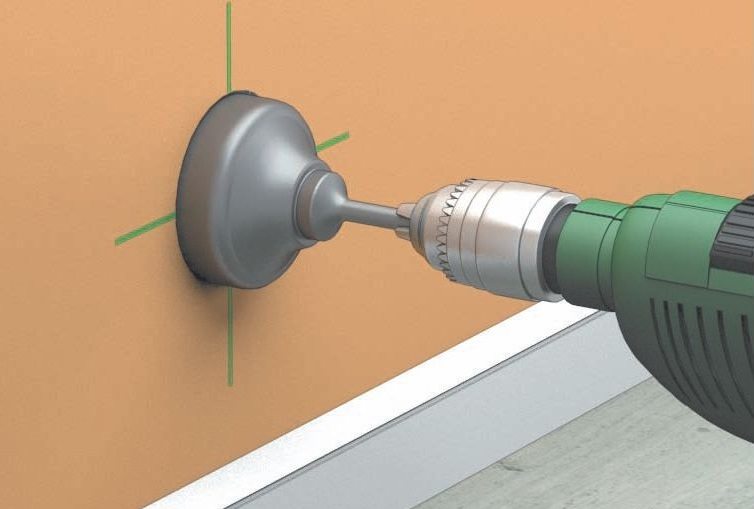

After laying out the cable route, mark it directly on the wall with a marker. Also mark the location where you'll need to drill a hole for the electrical box. Further steps will depend on the material of the wall you need to cut the channel into.

If the wall is made of soft material, chasing can be done the old-fashioned way, using a hammer and chisel. If the wall is made of reinforced concrete, you'll need to use a hammer drill and grinder. We'll use the hammer drill to drill holes along the future gutter, then connect them with a chisel and hammer. We'll inevitably encounter rebar along the way. It's not advisable to run wires under it, so we'll use a grinder to partially remove it.

We'll start running the electrical cable from the panel to the outlet. We'll mark the connection points for the electrical cable (live, neutral, and ground), but we won't connect the wire yet. We'll also need to install a differential switch in the panel. We'll run the neutral and live wires through the differential switch, and connect the ground separately.

It is worth reminding that all connections must be carefully insulated.

We pull the wire out of the electrical panel and run it along the cut channel. At the same time, we can place a plastic conduit into the cut channel, enclosing the copper wire. Once the wire is brought to the outlet location, we leave it alone for now and move on to installing the outlet itself.

- We use a hammer drill to drill a hole in the socket box (for convenience, you can use a special drill).

- We insert the flush-mounted box into the recess and “seal” it using cold welding or sealant.

- We bring the ends of the wires into the socket box.

- We unpack the new moisture-resistant socket and take out its “guts”.

- We connect the phase, neutral and ground wires to the corresponding contacts of the socket.

- We secure the socket base in the socket box so that it sits firmly and does not wobble.

- We screw on the plastic part of the socket and make sure that nothing is loose.

That's practically it. All that remains is to connect the live, neutral, and ground wires in the electrical panel and test the outlet by connecting, for example, a table lamp to it. You can use a tester to check if the washing machine outlet is receiving power. If the outlet is working properly, the final step is to tidy up the wall by sealing the groove where the wire and cable duct are located.

Finally, it's important to consider the electrical wiring for your washing machine in advance. It's important not only to select the right wire but also to plan the line's placement and protection. If you are not confident in your electrical skills, it is better to call a professional who can help you lay the cable and connect the outlet. Good luck!

Interesting:

9 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

The washing machine consumes the greatest current when heating water for washing, and when spinning - no more than 1A (depending on the motor power).

Certainly.

The washing machine consumes the most power when heating water, not when spinning clothes.

Typo. 2500 W, not kW.

I also noticed, 2.5 MW is an incredible machine.

The 2500 kW count made me smile...

Is it worth getting a three-core cable for an apartment (with grounding)?

No.

It is prohibited to cut grooves into walls, as this may lead to the destruction of the house.