What cable cross-section is needed for a tumble dryer?

When preparing for a major kitchen or bathroom renovation, it's crucial to plan the layout of electrical and other utilities in advance. Even if you don't yet know what appliances you'll be installing in these spaces, it's still worth considering ahead of time. In today's article, we'll explain the correct wire gauge for your dryer and explain how to prepare the electrical system.

When preparing for a major kitchen or bathroom renovation, it's crucial to plan the layout of electrical and other utilities in advance. Even if you don't yet know what appliances you'll be installing in these spaces, it's still worth considering ahead of time. In today's article, we'll explain the correct wire gauge for your dryer and explain how to prepare the electrical system.

Dryer power cord

Before starting work, carefully consider your cable selection: determine its cross-section, number of strands, and material, as an incorrectly selected connector can lead to overheating and malfunctions. Be sure to determine the wattage of your dryer. This value is usually indicated on the dryer itself or in the instructions. A device's scalar physical unit is measured in watts or kilowatts. For example, if your dryer's wattage is 5 kW, it's best to use a 6 kW cable.

An equally important factor is the distance from the electrical panel to the dryer. The greater the distance, the thicker the wire you'll need, because resistance increases with distance, ultimately reducing voltage. Pay attention to the material as well. Experts recommend avoiding aluminum wire for connecting large appliances. They believe copper conductors are a more reliable choice, so it's best to opt for them.

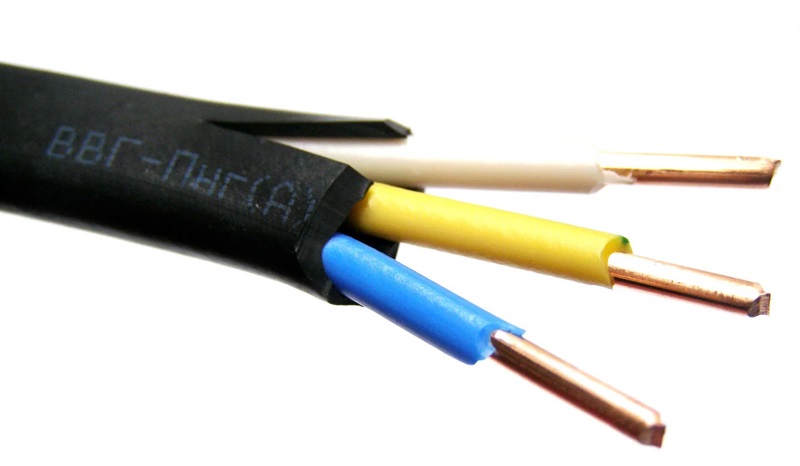

Next, you need to decide on the number of wires. According to technical standards, the power cord of any modern drying equipment must be grounded, which means a special outlet will need to be installed. You should choose a wire with three wires: one for the live wire, one for neutral, and one for ground.

Choosing the wrong electrical product can lead to overheating and short circuits, which is dangerous for you and your home!

Now we need to calculate the cross-section of the three-wire cable that will be used to install the outlet. We could share a table showing the cross-section, current, and power rating of a cable of the corresponding thickness, but we decided not to. Firstly, the average power rating of a device is 2500 kW. Secondly, we mentioned earlier that, just in case, it's best to choose a conductor with a reserve load. Based on the information we received and the recommendations of experienced professionals, we opted for a three-wire copper cable with a cross-section of 2.5 mm and high-quality insulation.

It's worth noting that the drying unit includes a whole complex of wires and connections. These are what supply it with power. These include:

- network conductor;

- control and ground cable (one is used for signal transmission, the other for safety);

- other wires (from the fan or lighting power supply).

If you're still having trouble choosing an electrical conductor, it's best to consult a qualified professional. They'll perform calculations taking all necessary factors into account and provide recommendations on choosing the optimal conductor for your dryer. This way, you can avoid any unexpected consequences.

Other components for connecting the dryer

A tumble dryer is a wonderful device that makes drying clothes convenient. However, to connect one, you need not only the dryer itself, but also several additional components. A cord alone won't suffice; you'll also need:

- moisture-resistant socket;

- residual current circuit breaker;

- copper terminals and flush-mounted box;

- plastic cable channel.

Waterproof sockets are essential, as the dryer will be used in bathrooms and kitchens where moisture and condensation are present. Installing a residual-current circuit breaker (RCCB) will provide reliable protection against potential power outages. Using copper terminals will help ensure a secure connection between wiring components, but ideally, it is best to avoid unnecessary connections. Connecting copper and aluminum wires is prohibited. Safety should be prioritized over cost savings.

When installing a heavy-duty electrical outlet, it's important to choose only high-quality electrical boxes to prevent fire hazards. By choosing high-quality products, you ensure safe operation and avoid future problems. Plastic cable trays should also be made from the highest-quality materials.

Some electrical installation professionals believe that running a wire through a channel cut into a wall doesn't require additional protection, as the conductor itself is insulated. However, we recommend providing protection for unexpected circumstances. This can be achieved using conduit.

Maybe it's worth saving money and connecting the dryer via an extension cord?

Many people strive to save on electrical bills. While this is generally understandable, it's important to remember that this approach can have serious consequences. A tumble dryer should not:

- connect to the socket via an extension cord;

- connect to a socket to which a large energy consumer is already connected;

- connect to a socket with unreliable wiring.

Why are these restrictions in place? It's actually quite simple: a clothes dryer consumes a large amount of electricity, which puts a significant strain on the electrical system. The maximum voltage occurs when the dryer is operating in intensive drying mode at a high temperature.

At such moments, the aluminum wires in the socket can overheat and be a potential cause of fire!

The best solution here is to run an additional wire from the electrical panel to the dryer's location. It must be of the appropriate cross-section and made of suitable material to ensure safe and reliable power to the moisture-resistant outlet where the dryer will be connected. This approach will prevent the risk of fire and preserve the integrity of your expensive appliance.

Preparing the electrical network for the dryer

Before laying and connecting the conductor, it's necessary to determine the optimal location for the outlet. It's important to consider not only its height but also its distance from the distribution board. It is important to remember that the further the outlet is from it, the more materials will be required, and the work of cutting grooves in the wall for the wire will be long. This process is quite labor-intensive, so careful consideration must be given to choosing the installation location.

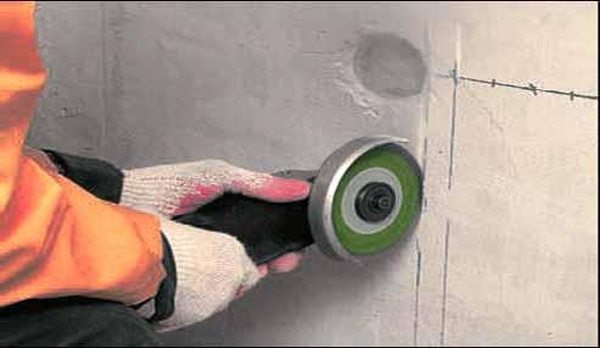

Once you've laid out the wire route, be sure to mark it on the wall with a marker. Also, indicate the location where you'll need to drill a hole for the electrical box. All subsequent steps will depend on the material of the wall you're cutting the channel into.

If the concrete is made of soft materials, traditional methods using a hammer and chisel can be used. For reinforced concrete, a chaser or a rotary hammer combined with a grinder will be required. Using a rotary hammer, we drill holes along the future channel and then connect them using a chisel and hammer. We'll encounter rebar along the way, and to facilitate the passage of the wire, we'll need to partially remove it with a grinder.

We'll start running the electrical wire from the panel to the outlet. We'll determine the locations for the wires (live, neutral, and ground), but won't connect them yet. A residual-current circuit breaker (RCD) will also need to be installed in the panel. We'll run the neutral and live wires through the RCD, and connect the ground separately.

It's also important to remember that all connections must be carefully insulated. Pull the wire out of the electrical panel and run it along the cut channel. You can also insert a plastic cable into it, tucking the copper conductor inside. Once it reaches the outlet location, leave it alone and move on to the outlet itself. You'll need:

- make a hole in the socket box with a hammer drill (for convenience, you can use a special drill);

- insert the socket box into the recess and secure it with cold welding or sealant;

- bring the ends of the wires into it;

- unpack the new moisture-resistant socket and then connect the phase, neutral and ground wires to the corresponding contacts;

- then secure the base in the socket box so that it sits firmly;

- Screw on the plastic part of the socket and make sure that nothing is loose.

The final steps remain. Connect the live, neutral, and ground wires in the electrical panel, and then plug a table lamp into the outlet. You can also use a power tester to check for power. Once you've verified the outlet is working properly, you can finish the job by sealing the cut-out wall and tuck the wires into a dedicated cable channel.

As you can see, it's important to consider the dryer's electrical connections in advance. It's crucial not only to choose the right wire but also to consider the line's placement and protection. If you're unsure about your electrical skills, we recommend consulting a professional who can install everything in accordance with all safety requirements.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment