Drainage device in a washing machine

An automatic washing machine cannot operate without a drainage system. After each cycle, the soapy water must be removed from the drum, which is what the pump does. The liquid passes through the pipes and filter before entering the sewer. If the washing machine suddenly fails to drain, several components need to be checked. We'll explain how the drainage system works in a washing machine and figure out how to fix a washing machine that refuses to empty the drum.

An automatic washing machine cannot operate without a drainage system. After each cycle, the soapy water must be removed from the drum, which is what the pump does. The liquid passes through the pipes and filter before entering the sewer. If the washing machine suddenly fails to drain, several components need to be checked. We'll explain how the drainage system works in a washing machine and figure out how to fix a washing machine that refuses to empty the drum.

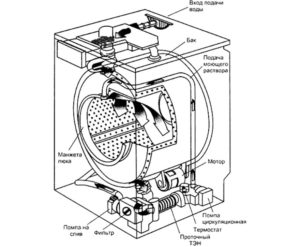

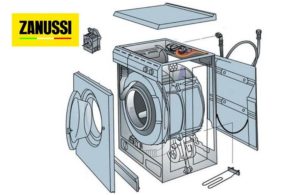

Elements of the water removal system

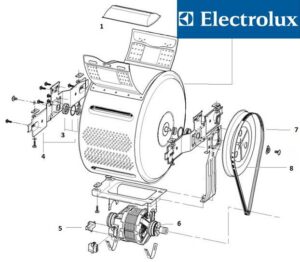

In fact, the drainage system is simple. If drainage problems arise, the user can easily check the machine themselves and find the weak point. Let's explain the components of the unit. The following is responsible for the proper drainage of water from the tank of any automatic washing machine:

- drain pipe;

- pump;

- trash filter;

- drainage hose.

The drain pipe is the first line of defense against wastewater. It connects the tank to the pump. At the beginning of the corrugated pipe, there's a thicker area—a plastic ball that acts as a check valve. This ball's purpose is to prevent unpleasant odors and sewage from entering the washing machine.

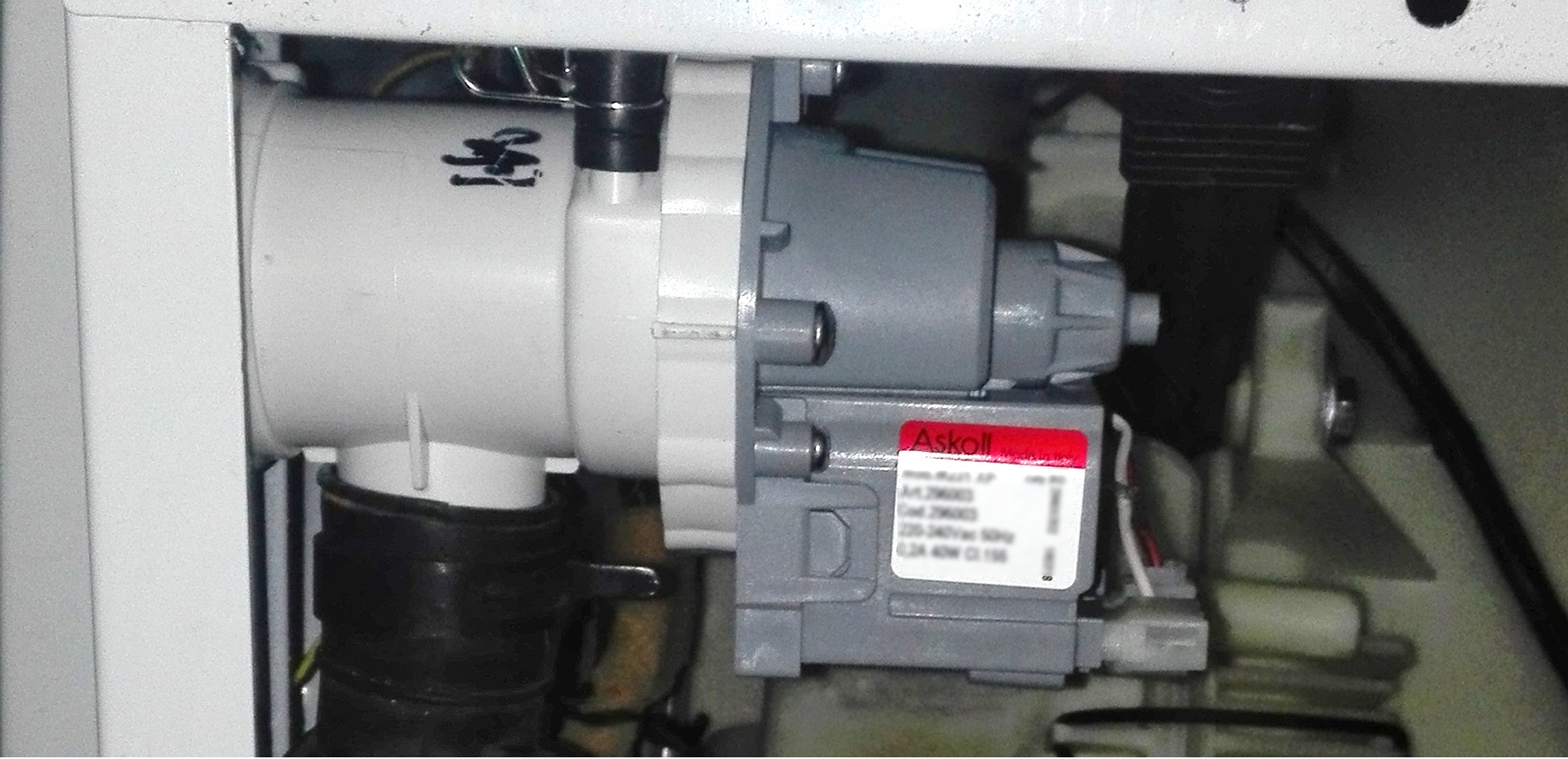

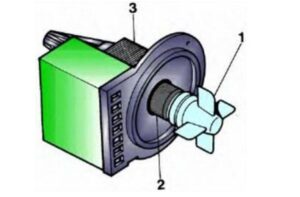

The main element of the drainage system is the pump, which consists of a working chamber and an electric motor.

The pump's working chamber is plastic, and the pipes are connected to it. The pump housing handles the pumping process. A debris filter is inserted into the end of the element to protect the pumping station from foreign objects. The pump motor has a pair of cores, which also contain the winding. The rotor rotates inside, and the impeller is fixed to it. All pump components are "hidden" within the plastic casing. The wiring terminals are exposed.

The normal voltage for a washing machine pump is 220 V. Pump power, depending on the machine model, ranges from 30 to 80 watts. The windings can be made of copper or aluminum. Power is supplied to the element by the main control module.

The pumping station operates on a simple principle. The pump is installed below the tank, ensuring a constant supply of water in the working chamber. When the module applies power, the motor wheel is set in motion. A vacuum is created in the supply pipe and pressure in the inlet pipe. This causes liquid to be drawn from the tank.

Finally, the water enters the drain hose. One end is connected to the pump's working chamber, and the other to the outlet of the sewer pipe. It is important to connect the drain hose correctly – it should be located at a distance of 50-70 cm from the floor level. If you ignore this rule, the water will drain from the tank by gravity.

How to check and replace the pump?

After several years of use, your washing machine may develop drainage problems. Drainage system components often become clogged. A simple cleaning can restore the machine to working order. Breakdowns can also occur. For example, the pump may burn out or the hose may crack. In these cases, the components will need to be replaced. To find and fix the problem, you'll need to inspect all components of the drainage system.

The drainage system can be accessed through the service hatch or the lower decorative panel of the housing.

You can open the door or remove the false panel with a screwdriver. You'll need to pry the cover and release the clips. Then, inspect the debris filter and part of the drain pump. The procedure is as follows:

- unplug the washing machine;

- turn off the valve responsible for the water supply;

- open the hatch or remove the lower decorative panel;

- find the trash filter;

- Cover the floor around the machine with dry rags, place a low container under the washing machine in the area where the filter is located;

- Unscrew the waste container plug half a turn. Be aware that water will flow out of the hole;

- wash the drain filter, clean the seat from dirt;

- shine a flashlight into the resulting hole – this way you can see the pump impeller;

- remove any debris that has wrapped around the blades;

- Using a long stick, try to spin the impeller – it should move intermittently, but freely.

If the impeller is moving with difficulty, it's likely that a foreign object is lodged between its blades. To clean the element, you'll need to remove the pump from the housing. This is done as follows:

- Place the machine on its left side. It is better to cover the floor with something soft beforehand;

- if there is a bottom, unscrew the fasteners and remove it;

- Find the pump – it is located just under the tank.

Before dismantling the pump, it is recommended to check it. Pump diagnostics can be performed using a multimeter. To do this, place the tester probes on the element's contacts, set the device to 700 V, plug in the machine, and start the "Drain" mode. After a couple of minutes, check the multimeter readings. If the pump doesn't hum at 220 V, it's likely faulty.

The pump cannot be repaired; the element will need to be replaced.

To remove the pump, disconnect the hoses and wiring, unscrew the bolts holding it in place, and remove the component. The new component is secured in place with screws, and the previously removed connectors and hoses are connected to it.

Replacing the drain hose

Sometimes you may need to replace your washing machine's drain hose. The job is fairly simple, and even a novice can handle it. Here's the procedure:

- de-energize the washing machine and disconnect it from communications;

- drain the remaining water from the system through the waste filter;

- move the washing machine away from the wall;

- tilt the machine body to gain free access to its bottom;

- find the place where the sleeve is fixed on the pump;

- loosen the clamp;

- disconnect the corrugated pipe from the housing;

- attach the new hose to the pump and secure it with a clamp;

- connect the corrugated pipe to the body;

- put the machine back in place.

To ensure the replacement was completed correctly, run a test wash with the drum empty. Wait for the machine to drain. Check for leaks. If any drips appear at the joints or the corrugated tube itself, complete the cycle and tighten the fasteners more firmly.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment