Why does the belt slip off on my washing machine?

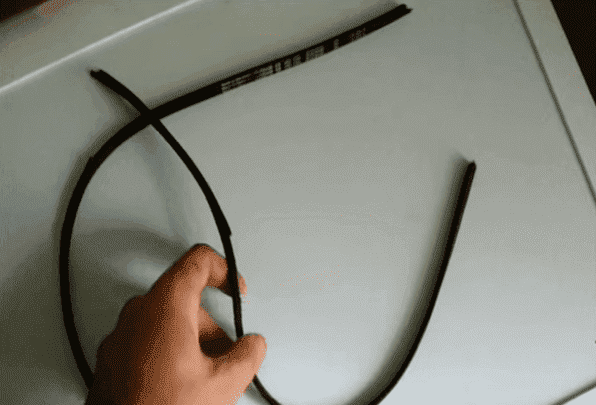

The drive belt is an essential component in automatic washing machines equipped with a commutator motor. It transmits impulses from the motor to the pulley, thereby rotating the drum. If the belt stretches, the machine's operation will be impaired.

The drive belt is an essential component in automatic washing machines equipped with a commutator motor. It transmits impulses from the motor to the pulley, thereby rotating the drum. If the belt stretches, the machine's operation will be impaired.

What should you do if your washing machine belt breaks? Should you take it to a service center or try to repair it yourself? Let's figure out what to do in this situation.

Why did the drive element fall off?

Before buying new parts for your washing machine, you should make sure the problem is definitely with the drive mechanism. The belt can slip off the drum for a variety of reasons. The main ones are:

- failure by the user to comply with the maximum permissible loading weight. If the washing machine is regularly operated under increased load, the belt will fall off after some time. When the elastic comes off for the first time, you can put it back on, but if the “incident” happens again, you will have to replace the element;

- Natural wear and tear. Over time, the rubber band stretches and begins to slip off the pulley. In this situation, the drive belt will need to be replaced;

- Loosening of the motor mount. During operation, the constant shaking of the machine can cause various components, including the motor, to loosen. This causes the motor to wobble, stretching the belt. The solution is simple: tighten the component more tightly.

- Deformation of the pulley or shaft. You can try to straighten the "wheel." However, in most cases, replacement of the parts is required;

- Loosening the pulley retaining bolt. In this situation, simply tightening the fastener will stop the wheel from wobbling;

- U-joint defect. If this part, which connects the shaft to the housing, is damaged, the drive belt will begin to fall off. Replacing it will solve the problem;

- Bearing assembly damage. Broken bearings cause the system to become unbalanced, making belt slippage inevitable. In this situation, the rings and seals will need to be replaced.

To diagnose the washing machine, simply remove the rear panel of the housing – this will allow you to inspect all elements of the drive system.

The drive belt can also slip if the washing machine is being used for the first time after a long period of inactivity. This is because the rubber dries out and cracks due to inactivity. Repair will require replacement.

Should I invite a professional?

Calling a technician to fix the problem is recommended if you have neither the time nor the inclination to deal with the issue. In any case, it's recommended to contact a reputable service center rather than a "home repairman," because:

- they provide a guarantee for the work performed;

- the likelihood that original parts will be used for repairs increases.

Large service centers are able to perform repairs more efficiently and also provide a guarantee on all work performed.

You should seek professional help only if there are serious problems, such as a defective universal joint or damaged bearings. If the belt is damaged due to wear, you can tighten a new one yourself. We'll explain how.

We put the belt back in place ourselves

Changing a belt doesn't require any special knowledge. All it takes is physical strength and some skill. The new rubber band is quite tight, so you'll need to work hard to get it onto the pulley. The procedure is as follows:

- unplug the washing machine;

- disconnect the drain and filler hoses from the body;

- unscrew a couple of bolts and remove the “top” of the machine by sliding the housing element back;

- remove the screws securing the rear panel of the case, remove the wall;

- pull the belt onto the engine shaft (use a screwdriver to make it easier to pull);

- place a piece of rubber on the drum pulley and slowly rotate the “wheel” to tighten the belt completely;

- turn the drum pulley - it should rotate slightly stiffly;

- check that the belt fits tightly into the grooves;

- Assemble the washing machine body, putting the back and top panels back in place.

When purchasing a new belt, consider the model of your automatic vehicle. It's best to buy factory-fitted components. You can also bring your old belt to the store and ask the salesperson to find an alternative.

The belt may "jump off" again

Installing a new rubber band does not always help to forget about the problem for a long time. If the belt slips again within 2-3 months after replacement, an in-depth diagnosis of the drive system components will be required. There is no point in tightening it again, sooner or later the problem will reoccur.

If the drive belt repeatedly loses its fixation, check to see if the pulley or motor fasteners are loose, or if the crosspiece or shaft is deformed.

If the bearings are damaged, they need to be replaced as soon as possible. A characteristic symptom of a malfunction is a loud rattling noise when the washing machine is running. Rusty stains on the back wall of the drum also indicate problems with the rings and seal.

Drive belts often slip due to systematic overloading of the washing machine. Therefore, it's crucial to monitor the amount of laundry you load into the drum. Information on how to properly load the machine can be found in the user manual.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment