The drum in the washing machine came off

Certain malfunctions are impossible to miss. For example, if the drum in a washing machine comes off the shaft, the user immediately realizes something is wrong. Visually, the centrifuge is noticeably displaced downwards, making it appear as if it has simply come loose. Let's look at what causes this problem and how to fix it.

Certain malfunctions are impossible to miss. For example, if the drum in a washing machine comes off the shaft, the user immediately realizes something is wrong. Visually, the centrifuge is noticeably displaced downwards, making it appear as if it has simply come loose. Let's look at what causes this problem and how to fix it.

Causes of drum displacement

If you suspect the drum is warped, immediately perform a quick diagnostic on your washing machine. Unplug your "home helper" and begin the inspection. What should you do in this situation?

- Open the hatch, rotate the drum manually, and rock it left, right, forward, and backward. If you notice significant play, the tank has indeed shifted. The bearings may have failed, causing the problem.

- Run the spin cycle at the maximum spin speed. A loud hum, grinding noise, or the sound of the drum slamming against the walls of the tank will indicate a malfunction. The cause of the misalignment may be worn shock absorbers or broken bearings.

- Spin the drum manually. If it moves with difficulty or makes unusual sounds, it may be broken. This could be caused by a slipped drive belt. Another possible cause is damage to the drum spider.

During diagnostics, be sure to inspect the rear of the drum. If rusty stains or wear marks are visible on the plastic, the drum "problems" are caused by broken bearings and a leaky seal.

In general, drum distortion is most often observed for the following reasons:

- crosspiece breakage;

- damage or wear of the drive belt;

- changing the shape of the shaft;

- wear of the bearing unit;

- failure of dampers or suspension springs.

If you think the drum has come loose, it's best to play it safe and avoid using the washing machine. You can diagnose the problem yourself. We'll explain where to start and how to get your "home helper" back in working order.

We determine the cause of the malfunction and eliminate it.

What should you do first? Once you notice the drum is warped, you'll need to eliminate one possible cause after another. It's recommended to proceed from the simplest to the most complex. First, inspect the drive belt. To do this:

- Unplug the machine's power cord from the socket;

- remove the back wall of the case by unscrewing all the screws that secure it (for some models of washing machines, you will first have to remove the top cover);

- Assess the condition of the belt.

Ideally, it should be tightly stretched between the drum and the motor. If the belt has come off, replace it. If you notice that the elastic has broken, purchase a new belt. When purchasing components, be sure to refer to the model and serial number of your washing machine.

Once you've confirmed the drive belt is in good condition, check the shock-absorbing system. If the drum is collapsing into the housing, the cause is likely broken springs. During the wash and spin cycles, these metal springs hold the drum in place, preventing it from slipping.

If even one shock-absorbing spring breaks, the drum will shift and the washing machine will not function properly.

Typically, the tank is held in place by two springs: a lower and an upper one. Removing the parts shouldn't be a problem. First, detach the end of the spring from the tank, then from the body. The new shock absorber is installed in the same manner.

The problem may not be the spring, but a broken damper. To remove the component, you'll need to remove the front housing panel. The procedure is as follows:

- remove the top cover of the case;

- remove the lower false panel behind which the waste filter is hidden;

- remove the powder container from the machine;

- Unscrew the screws holding the control panel;

- Place the “dashboard” carefully on the washing machine so as not to damage the wiring;

- Unscrew the bolts securing the front wall and detach it from the body.

This allows you to easily access the dampers. The lower part is secured to the housing with a bolt, while the opposite part is connected to the tank with latches. Loosen the screw and release the latches. Then remove the damaged damper element.

Next, you need to install the new shock absorbers in their original place. It is important to secure the dampers well so that the drum does not come off during the spin cycle in the future. The shock absorbing elements will begin to support the tank again, and the tilt will be eliminated.

Problem with the bearing unit

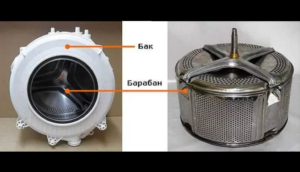

If the drum has come loose from the shaft, it means the washing machine has been running for a long time with worn-out bearings. Repairing the bearing assembly is quite labor-intensive, but it's possible to do it yourself.

Bearing wear can be judged by:

- rusty stains on the back of the tank;

- grinding and rattling sounds coming from the working machine;

- constant "jumping" of the technique during the push-up.

If you notice any of the signs indicating damage to the bearings, check the unit immediately; do not wait until the shaft is deformed or the drum crosspiece breaks.

To remove the old bearings and install new ones, you need to remove the tank from the housing and split the reservoir in half. If the tank is non-separable, you'll need to cut it with a hacksaw. If you plan to replace components, it's best to purchase a ready-made repair kit, which will include:

- 2 bearings;

- gland;

- special lubricant.

To replace the bearings, you need to split the tank in half, knock out the broken rings, and press new ones into place. Place a greased oil seal on top. Reassemble the housing in reverse order.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment