The Atlant washing machine does not spin.

If the wash cycle has finished but the water hasn't drained completely or the laundry remains too wet, your Atlant washing machine isn't spinning. This situation is common, but poor spinning isn't always caused by a major malfunction. An imbalance or simple carelessness could be to blame. We'll explore why the drum isn't spinning at full speed and how to fix this problem yourself. We'll cover all the common problems and how to fix them.

If the wash cycle has finished but the water hasn't drained completely or the laundry remains too wet, your Atlant washing machine isn't spinning. This situation is common, but poor spinning isn't always caused by a major malfunction. An imbalance or simple carelessness could be to blame. We'll explore why the drum isn't spinning at full speed and how to fix this problem yourself. We'll cover all the common problems and how to fix them.

Where to look for a breakdown?

You can resign yourself to wet laundry by removing it from the drum and spinning it by hand over the bathtub. But this not only takes a lot of effort and time, but also puts your washing machine at risk. Ignoring suspicious "symptoms" can worsen the problem, even leading to the machine's death. It's better not to complicate your life, but to respond to the problem in a timely manner.

First, it's important to understand the malfunctions and failures that cause the spin cycle to stop working. On Atlant washing machines, the drum won't spin in the following situations:

- no spin mode is enabled;

- the drum is out of balance;

- the drainage system is not functioning;

- the tachometer sensor is broken;

- the electric motor does not accelerate;

- the bearing unit is damaged;

- the control board is out of order;

- The drum jammed due to a foreign object getting into the tank.

If your washing machine is under warranty, you are prohibited from opening the case yourself—all repairs must be performed at a service center.

In 99% of cases, you can fix a non-functioning spin cycle yourself. Simply check all the identified "weak points" of your Atlant washing machine, keeping safety precautions in mind. Specific instructions on what to do are provided below.

Error in mode selection

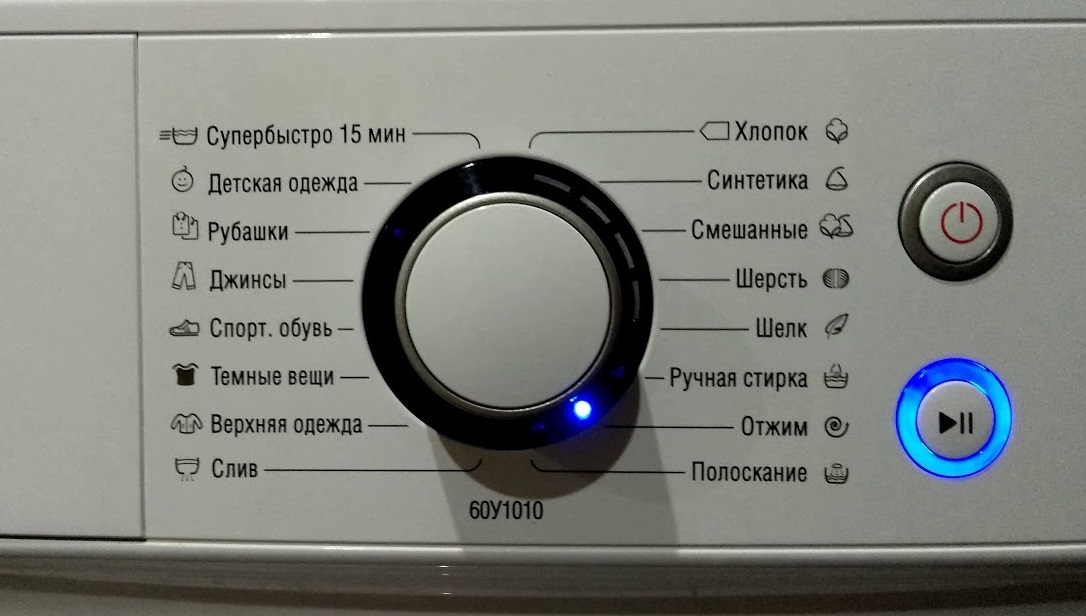

If your washing machine doesn't spin your laundry, don't panic. Often, it's not a malfunction, but a simple case of carelessness. For example, when the user accidentally selects a mode that automatically sets the spin speed to the minimum—400-600 rpm. Basic programs that include these include "Down," "Wool," "Curtains," "Delicate," "Hand Wash," and "Silk."

Confirming or disproving your hunch is easy: remember which program you selected and read its instructions. Or, try a new cycle with a spin mode—"Spin," "Children's," "Cotton," or "Rapid." If the laundry in the drum dries, it means there was a mistake.

It is recommended to use the "Child Lock" option, which will prevent accidental changes to the cycle settings.

Don't forget about the possibility of accidentally reducing the drum's spin speed. Many modern washing machines allow you to easily change the factory settings, even canceling the spin cycle. It's enough to accidentally press one of the control buttons to change the speed from maximum to minimum. It's best to run a test wash and monitor the settings. If the spin cycle fails, proceed to troubleshooting.

It might be an imbalance.

The most common cause of a missing spin cycle is imbalance. Simply put, the drum spins out of alignment and begins banging against the walls of the drum. For safety reasons, the machine stops spinning, ending the cycle 7-15 minutes early, but the clothes don't spin.

Failure to properly load the drum (overloading or underloading) can lead to imbalance. Clumping of laundry, for example, when it gets caught in a hole in the duvet cover and is unevenly distributed across the walls, can also disrupt the balance. Modern machines are able to detect suspicious rocking and display a corresponding error code on the display. Older models simply stop the cycle, leaving users confused.

If you suspect an imbalance, you must:

- wait until the machine turns off the door lock;

- open the hatch and assess the situation (overload, underload or knocking down);

- solve the problem (by removing some of the laundry, adding more items, or breaking up the lump and distributing the clothes in the drum);

- close the door;

- activate spin;

- make sure the laundry is wrung out.

Failure to comply with loading standards will result in drum imbalance!

It's best to avoid imbalance and constantly monitor the load. Imbalance damages the bearing assembly, drum shaft, and shock-absorbing system, not to mention possible internal mechanical damage. Be sure to remember both the upper and lower limits (both are specified in the manufacturer's instructions). For example, an Atlant washing machine with a capacity of up to 5 kg washes 1 kg of laundry at a time, and for an 8-9 kg load, the minimum load limit is set to 2.5 kg.

Waste water discharge is not possible

It's a different matter if the water doesn't drain from the drum after the spin cycle. This is most likely due to a malfunctioning drainage system—the washing machine can't empty the drum due to a faulty pump, a blocked impeller, or a clog. To understand the cause of the problem and what to do, you'll need to check all the aforementioned issues one by one.

- Let's rule out a clogged drain. First, cover the hole with your hand, disconnect the drain hose from the sewer pipe, and lower it into the bathtub or sink. The main drain may be clogged.

- We probe the hose. Next, carefully inspect the drain hose for blockages and kinks. If any seals or foreign objects are noticed, disconnect the corrugated hose and rinse it under the tap.

- Let's check the filter. The debris filter is located in the lower right corner of the machine, behind the rectangular access hatch. Pry it up with a screwdriver, remove it, and, placing a basin underneath, unscrew the filter attachment. All stuck-on dirt must be removed.

- We examine the impeller and pump. The hole cleared of the filter is illuminated with a flashlight. We need to find the spool, remove any hair and lint from the blades, clean the pump housing, and test all contacts with a multimeter.

The waste filter is unscrewed strictly clockwise!

If the problem is a faulty pump or a damaged filter, repairs won't help; replacement of the damaged parts is recommended. Once all the repairs are complete, reassemble the machine and run a test wash. An empty drum after the spin cycle will rule out the drainage system as the culprit.

The tachometer sensor should be tested.

A washing machine won't spin if the tachogenerator is faulty. This device is also known as a Hall sensor, and it controls the motor's speed. If the device breaks down and stops recording the speed, the control board loses connection with the motor and, for the safety of the equipment, stops spinning.

The following reasons may cause problems with the tachometer sensor:

- repeated overload of the drum;

- long-term operation of the machine without a break;

- loose fixation of the device;

- loose contacts or damaged wires;

- sudden power surges or a short circuit.

To diagnose the Hall sensor yourself, remove the motor from its housing, locate the tachogenerator attached to it, and inspect it. Next, tighten the terminals, strip the wires, test the connections with a multimeter, and compare the results with the standard. If the device is faulty, replacement is necessary.

There is a problem with the engine

You can also troubleshoot problems with the motor yourself. Commutator motors slow down when the brushes are worn out or there are problems with the windings. To diagnose this, you need to remove the motor from the washing machine:

- we disconnect the equipment from the power supply and water supply;

- remove the back panel;

- remove the drive belt;

- we unhook the wiring and holding bolts;

- We rock the engine and take it out.

Electric brushes are always changed in pairs!

All that's left to do is clean the motor and inspect it, looking for signs of overheating (burnt smell, dark spots, charred insulation). Next, check the brushes: open the "cases" and measure the length of the "carbon." If the tip is shorter than 0.7-1.5 cm, replace it with new ones. Finally, test the winding with a multimeter.

There is something extra in the tank

A foreign object jamming the drum can also lead to poor spin results. Keys or coins left in a pocket can get stuck in the drum, causing it to become uncomfortably lodged and impede its rotation. Immediate action is necessary, otherwise the drum walls, whose market value is comparable to a new machine, will be damaged.

Before disassembling the machine, it's worth confirming the diagnosis. Unplug the machine, drain the water, open the door, and spin the drum. If the drum is difficult to spin, or you hear a creaking or cracking sound, there's a foreign object inside.

We proceed as follows:

- we disconnect the machine from the sewer and water supply;

- move it away from the wall;

- remove the back panel;

- we find the heating element;

- we take a photo of the "chip" with wires;

- we disconnect the wiring;

- unscrew the retaining bolts;

- we put the heating element aside;

- we shine a flashlight through the hole;

- We remove the stuck object by hand or with a metal hook.

We recommend not resting on your laurels, but taking advantage of the situation and performing an unscheduled cleaning of the heating element. Afterward, reassemble the machine and check that the drum spins freely. Then run a test wash and monitor the spin quality. If the items remain wet, continue troubleshooting.

Destruction of the bearing unit

If your washing machine isn't spinning, and is also making unusual noises, creaking, and rattling, it's time to check the bearing assembly. The seals may have become worn, no longer sealing properly, and water that has gotten onto the bearings has washed out the lubricant. The situation is restored by replacing all damaged parts.

Repairing the bearing assembly is a labor-intensive task. You'll need to purchase suitable replacement parts, then disassemble the machine almost completely, removing the counterweights, heating element, shock absorbers, and drum. Then, you'll need to knock out the stuck bearings without damaging the universal joint and drum shaft. Consequently, you'll need a significant amount of tools and consumables.

Before disassembling, it is worth studying the manufacturer's instructions and the electrical diagram of the Atlant washing machine.

Before attempting to repair a bearing assembly, it's important to assess your abilities and capabilities. Without experience and practice, it's easy to make the problem worse: damaging the wires, puncturing the tank, or bending the shaft. However, a repairman's services will also be expensive, as replacing bearings typically costs a third of the price of a new washing machine.

Something's wrong with the electronics

Worse, spinning is impossible due to electronic issues. The triac responsible for the motor burns out, causing the motor to lose connection with the board and fail to spin the drum to the required speed. The machine either spins weakly or doesn't start at all.

The difficulty is that attempting to diagnose the board yourself is strongly discouraged. Without practice and specialized equipment, one wrong move could worsen the problem beyond repair. It is better not to experiment and entrust the module to professionals. The price of reprogramming services is several times lower than the cost of a new electronic unit.

Interesting:

2 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Very practical and comprehensive. Thank you.

I regret buying this car. It creaks, everything is inconvenient, I bought it in November, and by March I already started having problems. It doesn't wring out.