Candy washing machine not filling with water

You can't wash clothes with an empty drum. If your Candy washing machine isn't filling with water and just hums, something's clearly wrong. Many things can cause problems with the drum filling—you'll need to check all the weak points and fix the problem. We'll explain where to start and how to finish.

You can't wash clothes with an empty drum. If your Candy washing machine isn't filling with water and just hums, something's clearly wrong. Many things can cause problems with the drum filling—you'll need to check all the weak points and fix the problem. We'll explain where to start and how to finish.

How to find a fault?

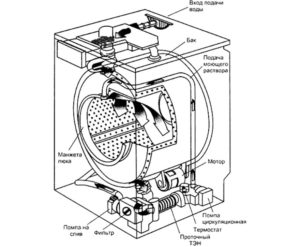

There are many reasons why the machine cannot fill with water. Problems with filling can be caused by a clogged inlet hose, a loosely closed hatch, or a failure of the control board. Troubleshooting is simplified by the fact that some malfunctions occur more frequently, while others, on the contrary, are very rare and manifest themselves with additional symptoms. Typically, the user will encounter one of the following malfunctions.

- The inlet valve is broken. In this case, the detergent drawer will remain dry, and the detergent added to it will remain intact. The final proof is to check the component: apply 220 volts to the valve and listen. If the membrane "triggers" and you hear a distinctive click, there is no problem with the circuit. The absence of sounds or other reactions indicates a faulty component. It will need to be removed and replaced with a new one.

- The inlet filter is clogged. To prevent debris from entering the machine from the water supply, the inlet hose has a protective filter mesh. If too much debris and limescale accumulates on it, water will not be able to flow into the machine. The washing machine will attempt to fill the drum, making an unusual humming noise.

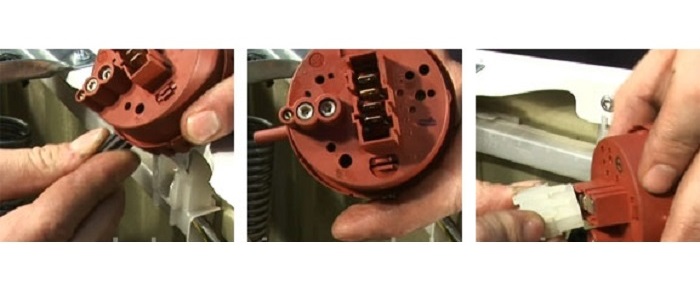

- The pressure switch is damaged. This component, also known as the water level sensor, monitors the water tank's fullness. A faulty device will not accurately measure the pressure and will signal the control board that the tank is full. Naturally, the module will receive this information and cancel the fill command. Verifying the pressure switch's functionality is easy: simply locate it and test it. It's located just under the top cover of the washing machine and consists of a washer and a long, downward-facing tube. To test, disconnect the hose from the housing and blow through it: if you hear clicking sounds, the sensor is working; if not, it's broken or clogged. In the latter case, it needs to be cleaned.

- The control board has failed. It's more complicated if the control module itself is blocking water intake—it doesn't recognize signals from the pressure switch and doesn't send commands to the pump and inlet valve. It's likely that resistors or circuits on the unit have burned out. Home diagnostics and repairs are not recommended in this case—only professionals with the appropriate experience and specialized equipment should repair electronics.

- The pump has burned out. Before filling with water, the system must ensure that the machine is capable of draining the collected liquid if necessary. If the pump is broken and doesn't signal its readiness to the control board, the unit won't start the wash cycle. Fixing the pump yourself is quite difficult; it's easier and more reliable to contact a professional.

The Candy washing machine does not fill with water due to problems with the filter mesh, inlet valve, pump, pressure switch or control board.

When inspecting the pressure switch, it's recommended to immediately check the condition of the wiring from the sensor to the tank. Over time, its insulation wears out and allows air to pass through, which interferes with tank pressure readings. A faulty locking mechanism can also prevent the machine from filling.

An empty drum isn't always caused by a malfunction. Often, the problem is a loose door—the circuit board detects a leak in the system and prevents water from filling. Try closing the machine again until the door lock clicks.

Hose and mesh filter

If Candy doesn't fill the tank after starting the program, but only makes a humming sound, it's likely the inlet filter or inlet hose is clogged. To check this and clear the blockage, you'll need to remove the corrugated hose: loosen the clamps, disconnect it from the body and pipes. Afterward, inspect the rubber for debris and kinks, then rinse it thoroughly under the tap. A heavily soiled sleeve with a thick layer of limescale and debris on the walls needs to be soaked in a warm lemon solution.

Replace the clean hose and restart the cycle. If the system doesn't restore itself, there's a problem with one of the filters. First, inspect and clean the mesh:

- loosen the clamp that secures the hose;

- we detach the hose from the washing machine body;

- we look into the valve and look for the filter mesh;

- Using pliers, grab the protrusion provided on the filter;

- pull the filter towards you, without rotating or applying strong pressure;

- We clean the nozzle with a toothpick or a needle, getting rid of all stuck debris;

- we wash the mesh under the tap;

- We return the filter to its seat and press it into the grooves.

If the filter mesh is clogged, the washing machine will not be able to fill the drum with water.

It's also recommended to immediately check the second filter, known as the "deep cleaning" filter. It's installed in the water pipe, immediately after the faucet, absorbing all the limescale, impurities, and dirt. There's only one way to fix this: take two wrenches, first securing the joint, and then loosen the retaining nut with the second. Then, place a large basin underneath and run a strong stream of water. The flow will clean the mesh on its own—just tighten the fastener after 2-3 minutes.

Inlet valve and heating element

A faulty inlet valve is one of the most common problems preventing water from filling the machine. A broken part cannot be repaired; it must be removed and replaced with a new one. Here's what to do:

- disconnect the inlet hose from the valve by loosening the clamp;

- drain the remaining water from the hose;

- unscrew the bolts securing the top cover of the housing;

- move the "top" aside;

- take a photo or remember the connection of the wires to the coil;

- release the wiring from the "chip";

- Use pliers to disconnect the pipes from the terminals and drain the water from them;

- unscrew the screw holding the valve;

- remove the valve from the housing;

- take a new valve and place it in the seat;

- secure the valve position with a screw, connect the previously removed pipes and wires;

- check the reliability and tightness of the fastenings;

- return the top cover to the case and secure it with bolts;

- Pull the inlet hose onto the valve and secure it with a clamp;

- plug the washing machine into the socket, open the water supply tap;

- Run a quick program and check if the water intake has been restored.

Candy also fails to fill with water if there's a problem with the heating element. This is because before starting the program, the board requests the readiness of all key components, including the heating element. A faulty heater is silent and prevents the cycle from starting. Most likely, the device failed due to a thick layer of scale or a breakdown.

The condition of the heating element is checked as follows:

- the rear panel of the case is removed;

- there is a heating element located under the drum;

- The contacts from the thermistor and the connected ground are disconnected using pliers;

- the central nut is loosened;

- the heater body is rocked and carefully removed from its seat along with the rubber gasket;

- the cuff is washed and returned to its place;

- a new heating element is installed and secured;

- the grounding and temperature sensor are connected back.

If everything is OK with the heating element, valve and filters, it’s worth check the UBLThe door likely isn't locking securely, and the circuit board is detecting poor drum sealing and is resetting the alarm. You'll need to disconnect the power to the washing machine and have the locking mechanism diagnosed.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment