The Candy washing machine is constantly filling with water.

If your Candy washing machine continually fills with water without starting a wash, there's a problem with the system. Ignoring this problem is impossible—the machine simply won't be able to continue its normal operation. Let's explore the possible causes of this incessant filling and what to do in this situation.

If your Candy washing machine continually fills with water without starting a wash, there's a problem with the system. Ignoring this problem is impossible—the machine simply won't be able to continue its normal operation. Let's explore the possible causes of this incessant filling and what to do in this situation.

Signs of a problem

During a standard cycle, a Candy machine fills the drum approximately four times. This happens during the main wash and during the rinse cycle. It's easy to tell that liquid is continuously being drawn into the drum. The following symptoms will indicate that the machine is having trouble filling:

- the constant noise of liquid being poured into the tank;

- Extended cycle. Since the machine is not functioning correctly, the program execution time is extended;

- Dirty and soapy items in the drum. Because the soap solution isn't reaching the required concentration, the laundry can't be washed properly.

If you notice that your usual cycle is taking 30-40 minutes longer, monitor your washing machine. Run a cycle and check for any issues with water intake. The same applies if there's a lot of detergent and soap residue left on your clothes after washing.

It is dangerous to operate a washing machine that has problems with water intake.

Potential culprits of the breakdown

There may be various reasons why a Candy washing machine is constantly filling with water. First, it's important to identify all possible causes and eliminate them one by one during diagnostics. Continuous liquid intake may be caused by:

There may be various reasons why a Candy washing machine is constantly filling with water. First, it's important to identify all possible causes and eliminate them one by one during diagnostics. Continuous liquid intake may be caused by:

- a hole in the machine's tank;

- broken water level sensor;

- incorrectly functioning intake valve;

- damaged control module.

It is important to check each of the elements. Very often, continuous water intake occurs when the machine is incorrectly connected to the house utilities. While some problems can be easily fixed yourself, more complex repairs will require a professional. We'll explain what to do if you detect a problem.

Incorrect installation of the drain hose

Home appliance diagnostics always proceed from the simple to the complex. Therefore, experts recommend first checking whether the machine is properly connected to the sewer system. An incorrectly positioned drain hose could very well be the cause of the malfunction.

Washing machines always come with instructions outlining the basic installation guidelines. They even show how to connect the hoses to the house's plumbing. Unfortunately, many users ignore the manufacturer's recommendations and install the outlets incorrectly.

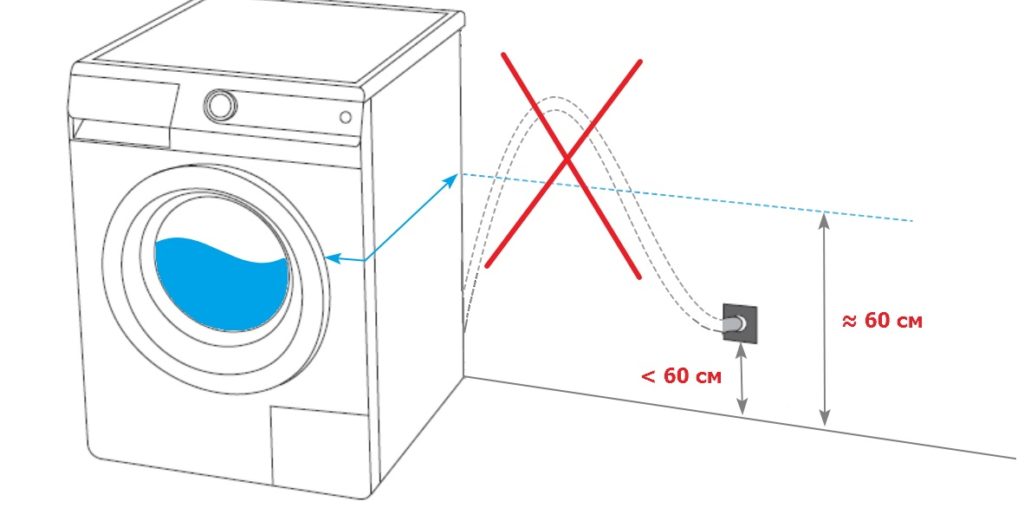

The drain hose must be located at a height of 50-60 cm from the floor, otherwise the water from the tank will drain by gravity.

If the drain hose is left on the floor, the water filling the machine will leak out of the system. The pressure switch, recognizing the empty tank, will send a signal to the circuit board, and the control unit will again command the inlet valve to fill the machine. This process can continue in a loop for a very long time.

Therefore, first, inspect the drain hose and ensure it's located at a sufficient distance from the floor. If visual inspection of the hose isn't possible, you can do it another way:

- turn on the equipment;

- activate any washing mode;

- wait until the washing machine fills with water;

- click on “Pause”, move the selector to the “Drain” mode;

- run the function;

- Pause the cycle in the middle of the "descent".

If water continues to slowly leak out of the tank after pausing, the drain hose is definitely the culprit. If the liquid level remains unchanged, further investigation is needed.

The fill valve does not hold

In some cases, a constant flooding is caused by a faulty inlet valve. This sensor can't stop water from entering the system. When the washing machine fills to the brim, the protection circuit is triggered and the drain is activated. What can I do to restore the machine's functionality?

First, observe the appliance. If water fills too slowly, the membrane is likely worn out. Rapid filling indicates a faulty electromagnetic sensor. The inlet valve cannot be repaired and will need to be replaced.

Once you've purchased a new part that's specifically designed for your Candy model, you can begin replacing the valve. To do this:

Once you've purchased a new part that's specifically designed for your Candy model, you can begin replacing the valve. To do this:

- de-energize the washing machine;

- remove the top cover of the housing on a front-loading washing machine, or the side cover on a vertical washing machine;

- find the fill valve;

- Take a photo of the connection diagram of the wires and pipes to the sensor;

- disconnect the wiring and tubes from the element;

- Remove the old valve. Depending on your washing machine model, you may need to either remove the bolts holding the part in place or loosen the retaining clips.

- Place the workpiece in place. Secure it with latches or screws;

- connect the previously removed wiring, connect the pipes;

- assemble the body.

To check if the replacement was performed correctly, run an empty wash cycle with the drum empty. Observe whether the problem is resolved. Removing the old valve and installing a new one is easy; you can do it yourself, without calling a professional.

Pressure switch

The water level sensor monitors the amount of water in the tank. When the desired level is reached, the pressure switch signals the machine's "brain." The control module, in turn, "commands" the machine to stop filling.

If the pressure switch fails, the electronic module receives false information about the water level in the machine.

This "commotion" disrupts the entire process. Incorrect sensor operation may be caused by:

- oxidation of its elements;

- short-circuiting of wires;

- damage to the fitting;

- clogging;

- membrane depressurization.

There are several ways to troubleshoot the problem. First, try repairing the pressure switch. Cleaning the contacts, removing blockages, or welding the defects might help. If there's no response, you'll have to install a new level sensor.

The sequence of actions is as follows:

- remove the top panel of the case by unscrewing the bolts that secure it;

- “unhook” the pressure tube from the pressure switch;

- remove the chip with wires;

- remove the level sensor by loosening the fasteners;

- install the serviceable part in place;

- connect the tube and wiring to the new pressure switch;

- Secure the machine cover with screws.

When repairing equipment yourself, it's essential to follow safety precautions. Always unplug the machine from the outlet and turn off the water supply before starting work.

It's important to purchase original components. The pressure switch must be compatible with the specific washing machine model.

Electronic filling

If diagnostics of all the described sensors and elements do not reveal any problems, it remains to check the main control unit. The electronic module completely controls the washing process; if it is damaged, the cycle may be disrupted.

If diagnostics of all the described sensors and elements do not reveal any problems, it remains to check the main control unit. The electronic module completely controls the washing process; if it is damaged, the cycle may be disrupted.

If any component of the control board is damaged, the "brain" cannot correctly recognize and transmit signals. For example, the pressure switch notifies that the tank is full, the module doesn't respond, the safety system drains the water, and the fluid continues to fill.

The reasons for damage to the electronic module may be the following:

- power surges;

- moisture getting on the board;

- wear of the element;

- a defect resulting from mechanical impact on the block.

If the control module is faulty, don't try to repair it. Messing around with electronics requires the appropriate knowledge and skills. An inexperienced person tinkering with the washing machine's "brains" can only make the situation worse.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment