Indesit washing machine won't spin

If your Indesit washing machine won't spin, don't give up and wring out the laundry by hand. A loose drum is the first sign of a problem, and leaving the problem undiagnosed and unfixed can worsen the situation, even leading to the entire machine failing. It's best to act quickly and begin troubleshooting immediately. What steps should you take?

If your Indesit washing machine won't spin, don't give up and wring out the laundry by hand. A loose drum is the first sign of a problem, and leaving the problem undiagnosed and unfixed can worsen the situation, even leading to the entire machine failing. It's best to act quickly and begin troubleshooting immediately. What steps should you take?

Main signs of malfunction

First, you need to recognize warning signs. It's not always the case that the washing machine simply slows down in the middle of a cycle; sometimes it signals a breakdown with a problematic drain or an unusual hum.As a rule, you should be wary if:

- the running program ended, but water remained in the drum;

- the items being taken out are completely wet;

- water drains very noisily or slowly;

- the machine spins intermittently or does not always respond to the set mode;

- The unit hums as if it were spinning, but the drum remains in place.

If you notice even one "symptom," you should be wary and investigate the cause of the spin cycle failure. Possible malfunctions range from minor, quickly fixable issues to major breakdowns requiring the replacement of expensive parts. What could happen?

- Overload or underweight. When the machine is overloaded or underloaded, the system automatically cancels the spin cycle for safety reasons. Otherwise, imbalance and internal mechanical damage may occur.

- Loose drive belt. The drum will not spin if the drive belt is stretched, slipped, or slipping on the pulley.

- Failure of the control board or its triacs. If the triac responsible for transmitting information from the engine burns out, the system is unable to monitor the situation and control the circuit breaker. An error is generated, and the electronics automatically shut down for safety reasons.

- Motor failure. It's logical that a motor that isn't operating at full power won't be able to accelerate the drum to the required speed. Slowdown can be caused by burnt wires, worn brushes, internal motor problems, or a faulty Hall sensor.

Knowing the signs and possible causes of a missing spin cycle makes it easier to determine the nature and extent of the problem. In any case, you need to take action and not let things slide. We'll explain what to do first and how to repair the machine below.

Initial actions

A non-spinning drum does not always indicate serious internal problems with the washing machine. Often the problem is simple carelessness, so it is recommended not to rush into disassembling the case.It would be better to conduct a check.

First of all, check if the no spin mode is turned on.

- Is the no-spin cycle enabled? Users often accidentally reduce the spin cycle to minimum or select the no-spin cycle "Delicates" or "Hand Wash."

- Is there a technical issue? Although rare, it does happen that the washing machine fails to spin due to a brief system failure. Simply unplug the machine, wait 10-20 minutes, and restart the cycle.

Another possible cause is overloading the drum. Exceeding the maximum load capacity is prohibited, as this can lead to imbalance, increased vibration, and mechanical damage. The same applies to a half-empty drum—the system won't risk automatically starting a cycle.

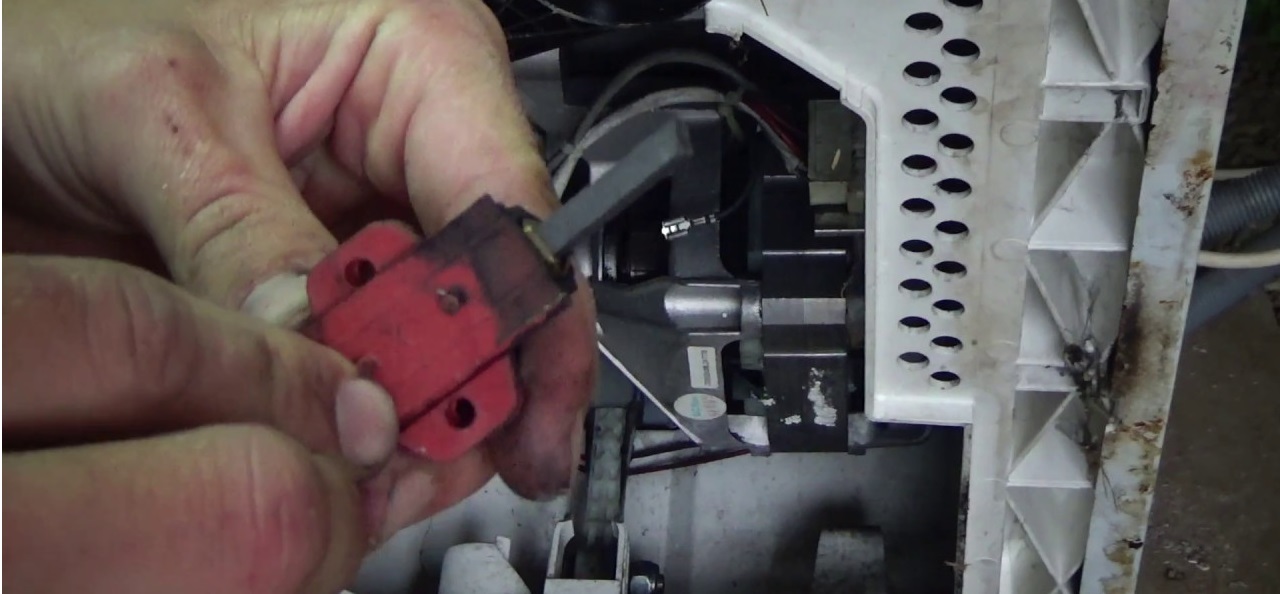

Let's check the electric brushes

Worn-out brushes often cause problematic spinning. Typically, in this case, the machine doesn't make a suspicious humming sound, but simply doesn't spin up to the required speed. Let's test this hypothesis:

- we disconnect the machine from communications and provide free access to the rear wall;

- remove the back panel by unscrewing the bolts around the perimeter;

- by rotating the pulley, we remove the drive belt;

- we unscrew the bolts holding the motor;

- we photograph the location of the wiring connected to the engine;

- we loosen the connected wiring;

- we rock the engine and remove it from its mounting location;

- We unfasten the brushes and look at the condition of the carbon tips.

If one of the graphite tips is severely worn, it needs to be replaced. It's important to replace the brushes only in pairs, regardless of the condition of the second one. Replacement parts should be purchased from the store strictly according to the original pattern and installed in reverse order, following the diagram already discussed.

Problems with the control module

Possible breakdowns include a faulty control board. Most likely, the triac responsible for the motor has burned out or the “track” soldered to it has become worn out. In any case, you need to remove the module and inspect it carefully.

- We disconnect the machine from the electricity.

- We remove the top cover.

- We take out the dispenser tray by pulling it towards ourselves.

- We unscrew the bolts holding the instrument panel.

- Having unlocked the plastic latches, we remove the panel.

- We release the connected wiring.

- We remove the module by releasing another pair of latches.

Often, a quick glance at the board is enough to spot burn marks, dark spots, or loose connections. If a visual inspection doesn't help, it's best to avoid further investigation and contact a service center.

Prevention of breakdowns

It's better to prevent problems than to look for them. Moreover, the basic rules for using the machine are simple and straightforward. So, you only need to:

- install the machine according to the instructions;

- carefully check the pockets of items loaded into the drum;

- sort things and use protective bags;

- connect the voltage stabilizer to the network;

- control the degree of tank loading;

- Clean and ventilate the machine regularly.

By catching problems with your spin cycle early, you can save a significant amount of time and money. Don't rely on luck, just get diagnostics done, and remember to take preventative measures.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment