The washing machine is stuck in the spin cycle and won't stop.

It's clear that if your washing machine doesn't stop during the spin cycle, there's something wrong. There could be several reasons, from a simple overloaded drum to problems with the bearing assembly or electronics. The self-diagnostic system won't help much here—the display will show a code indicating a general error—no spin cycle. You'll have to figure out what exactly is wrong with the machine yourself. We'll explain the best place to start when repairing your "home helper."

It's clear that if your washing machine doesn't stop during the spin cycle, there's something wrong. There could be several reasons, from a simple overloaded drum to problems with the bearing assembly or electronics. The self-diagnostic system won't help much here—the display will show a code indicating a general error—no spin cycle. You'll have to figure out what exactly is wrong with the machine yourself. We'll explain the best place to start when repairing your "home helper."

How to stop a "crazy" device?

What should you do if your washing machine is stuck in the spin cycle and won't stop spinning? Such “crazy” rotation at high speed can lead to overheating of the unit and failure of the bearings. So, first of all, you should turn off the washing machine, but how do you do this safely? Here's how: First, press the "Start/Pause" button. The drum should then begin to slow down. After a few seconds, the "centrifuge" will stop completely.

If turning off the button doesn't help, you'll just have to turn off the power to the machine by unplugging the power cord.

Of course, this is dangerous for the machine, but leaving it with the drum spinning for an extended period is no less dangerous. Therefore, without hesitation, unplug the appliance.

Why did this malfunction occur?

A washing machine performs many steps in a single cycle. First, it fills the drum by opening the inlet valve. The detergent mixes with water, and the motor begins to spin the drum. After completing the pre-wash, the machine drains the used liquid and refills, drawing detergent from another compartment in the drawer.

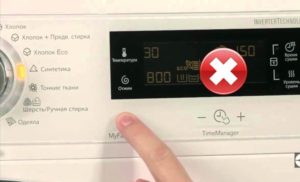

At the end of the main wash, the dirty water is drained again, and clean water is collected for rinsing. The final stage of the cycle is the spin cycle. This is where the problem occurs in our situation. For some reason, the machine fails to operate normally, freezing mid-cycle. Luckily, a faulty machine displays a system error code on the display, informing the user which component is faulty. However, sometimes the error code is not displayed, and the user must investigate the cause of the malfunction independently. In such situations, logic and knowledge of the automatic washing machine's design will help. First, it's important to rule out common user errors that can prevent the spin cycle from working properly. These include:

- machine overload;

- washing one, overly bulky item;

- the washing machine is not full enough;

- selecting a program that does not include spinning;

- A foreign object getting into the drum. A bra underwire, a bobby pin, a nail, or other object can jam the centrifuge, preventing the machine from accelerating the drum to the required speed.

When the washing machine is overloaded with laundry, the laundry becomes clumped together, causing the drum to become unbalanced. When the centrifuge spins too quickly, the heavy clump can easily disrupt the drive mechanism. Therefore, the machine immediately stops the cycle, pauses, and waits for the excess laundry to be removed.

A similar situation can arise when the machine is loaded with too few items. Modern washing machines easily detect this issue, pausing the spin cycle. Sometimes, a foreign object lodged between the tub and the drum can cause a malfunction. In such a situation, it is important to remove the item as quickly as possible, as it can not only cause the drum to jam, but also damage the plastic container, causing the machine to leak.

If all the above-mentioned causes have been ruled out, it's time to begin troubleshooting. To find the weak spot, you'll need to partially disassemble the machine. You can do this yourself. We'll explain which components typically fail and cause the washing machine to freeze during the spin cycle.

Bearing assembly and drive

Most often, problems with drum rotation are caused by damaged bearings. In this situation, the automatic machine will make a loud humming noise during operation, a grinding sound can be heard, and significant play in the centrifuge may be observed.

Broken bearings make it difficult for the drum to rotate, so the machine cannot reach the speed required for spinning and freezes.

If you don't want to repair your old washing machine, it's best to take it to a repair shop or buy a new one. If you don't want to spend extra money, you can do the repairs yourself. Replacing bearings is a complex process that requires a significant amount of time and effort. First, you need to purchase replacement components. They must be compatible with your specific washing machine model. Next, you'll need to almost completely disassemble the washing machine and remove the drum.

It's a good idea if your "home helper" has a detachable tank. Simply split it in half to access the drum, knock out the old bearings, press in new ones, and remember to replace the seal. Reassembly is done in reverse order.

If the unit is cast, repairs will take longer. First, the plastic is cut along the weld with a hacksaw, then the bearings and seal are replaced. When joining the halves, use a moisture-resistant silicone sealant to restore the tank's seal.

When the bearings are OK but the spin cycle is not running, watch how the machine runs just before it stalls. If you hear a barely perceptible whistle and the drum rotation speed slows down, be sure to inspect the drive belt. When the rubber band stretches, it "slips" on the pulley, causing the RPM to drop. To check the belt, you need to:

- de-energize the machine;

- turn off the water supply tap;

- remove the top panel of the machine;

- remove the back wall of the case by unscrewing the screws that secure it.

Inspect the drive belt. If it's damaged, replace the rubber. To do this:

- remove the old belt from the pulley;

- Pull the new rubber band first onto the engine pulley, then onto the drum “wheel”;

- Assemble the washing machine body in reverse order.

Of course, it's a good idea to immediately check the pulleys themselves for deformation. Pay particular attention to the drum wheel. Even a slight bend or burr will negatively affect the drive belt, leading to wear.

Engine and speed sensor

Next in line for inspection are the electric motor and tachometer. Often, the commutator loses power due to worn brushes. A “weak” motor is unable to accelerate the drum to high speeds, so the machine freezes during the spin cycle. To check the electric motor brushes, you should:

- de-energize the washing machine;

- close the shut-off valve responsible for the water supply;

- unhook the top cover of the machine by unscrewing the two bolts holding it;

- remove the back panel of the case;

- remove the drive belt from the pulleys;

- Disconnect the wiring from the engine. It's best to take a photo of the wiring diagram beforehand to avoid confusion during reassembly;

- unscrew a couple of bolts securing the motor;

- remove the engine from the housing;

- Unscrew the small screws located on the sides of the motor. They hold the carbon brushes in place;

- inspect the electric brushes and see how worn they are.

The brushes of the collector motor must be changed in pairs, even if one carbon rod is completely intact.

If the problem isn't with worn brushes, run a tachogenerator diagnostic. The Hall sensor is checked with a multimeter. Set the tester to ohmmeter mode and measure the resistance of the component. Normally, the device screen should display a value of approximately 60 ohms. Next, set the multimeter to voltage mode. While measuring the current at the tachogenerator terminals, use your free hand to rotate the motor. The reading on the screen should be approximately 0.2 V. The tachogenerator monitors the motor speed. If a faulty component is detected, it should be replaced. Otherwise, problems with the spin cycle will occur.

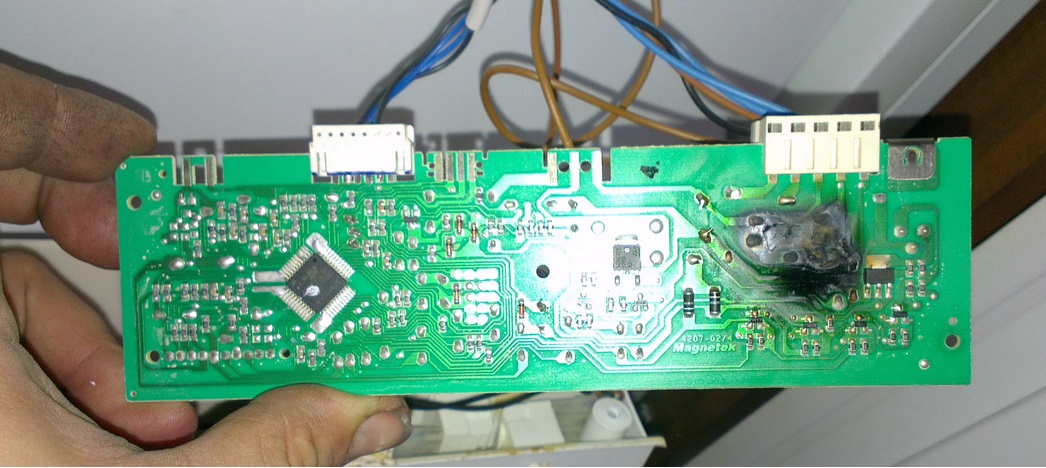

The electronics are malfunctioning

The most frustrating situation is when the washing machine freezes during the spin cycle due to a problem with the main control module. The electronic unit is a very complex component, requiring specialized knowledge and experience to operate. Therefore, it's best to entrust board repair to a specialist. A service center technician, using specialized equipment, will determine which component is faulty and, if necessary, replace the semiconductor or resolder the circuit boards. Messing with the machine's "brains" yourself is not recommended—it could actually cause further damage rather than help.

So, if your washing machine suddenly freezes while spinning, don't rush to call a repairman. You may have simply overloaded the load and exceeded the maximum load capacity. Or, conversely, you may have decided to run the machine half-empty. If the problem is a technical issue, try to identify the cause yourself. Even a novice can replace the motor brushes or install new bearings, provided they follow the instructions.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment