The drum in my Siemens washing machine won't spin.

It's easy to tell if your Siemens washing machine isn't spinning: the machine suddenly slows down and refuses to continue the cycle. Sometimes the cylinder becomes stuck—unable to turn even by hand. In any case, the laundry remains dirty, and the scheduled wash cycle is ruined. To restore the washing machine's functionality, it's essential to immediately begin troubleshooting and identify the cause of the malfunction. Let's take a closer look at what to check and how to fix it.

It's easy to tell if your Siemens washing machine isn't spinning: the machine suddenly slows down and refuses to continue the cycle. Sometimes the cylinder becomes stuck—unable to turn even by hand. In any case, the laundry remains dirty, and the scheduled wash cycle is ruined. To restore the washing machine's functionality, it's essential to immediately begin troubleshooting and identify the cause of the malfunction. Let's take a closer look at what to check and how to fix it.

The origin of this malfunction

It is impossible to determine by eye why the drum on a Siemens machine does not rotate. Several malfunctions can cause the machine to stop working, and the number of possible failures depends on the machine model, the components installed, and even the country of assembly. But, as a rule, sudden cylinder braking is caused by the following typical failures:

- the drum is jammed due to a solid object getting inside;

- the drive has become out of order (the drive belt has come off or the pulley has become damaged);

- the electric motor is broken (it doesn’t start at all or doesn’t accelerate to the set speed);

- the drum flaps suddenly opened (on Siemens with vertical loading);

- There were problems with the control board (individual triacs burned out or the module failed completely).

The list of possible causes of a drum stalling is far from exhaustive. Modern Siemens washing machines have complex electronics: the cylinder's operation is coordinated and controlled by numerous components, microelements, and sensors. The slightest malfunction in the system will result in a broken connection and the machine's shutdown.

In Siemens washing machines, the drum does not rotate if the motor is broken, the doors are open, a foreign object is stuck, or there are problems with the drive or control board.

Vague "symptoms" also complicate diagnosis. Signs of failure are very similar, and without a thorough examination of all possible culprits, pinpointing the problem is very difficult. Ideally, you should contact a service center, but if you want, you can identify the problem and fix it yourself. The main thing is to act promptly and follow the instructions. Below, we will discuss situations in which the drum does not rotate at all. If the cylinder rotates, albeit erratically, the list of possible causes will be significantly longer.

Problems with the drive part

If the washing machine suddenly stops rotating, the first thing to check is the drive belt—it's responsible for transmitting power from the motor to the drum shaft. If the belt breaks or comes off, the cylinder stops rotating. To reset the drive, you need to replace the "ring."

It's even worse if the belt breaks regularly, more than three times every six months. In this situation, simply replacing the rubber band isn't enough: you should also assess the condition of the rim and pulley. The wheel may be deformed, or the ring stretched. In this case, repair or replacement of the components will be necessary.

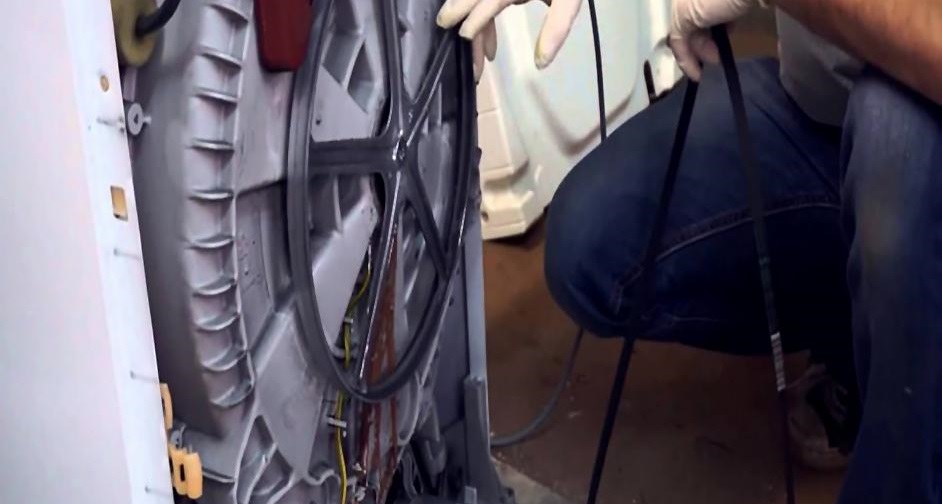

Before making a diagnosis, you need to inspect the belt. Here's what to do:

- disconnect Siemens from the power supply and water supply;

- turn the equipment with the rear panel forward;

- unscrew the back by loosening the corresponding bolts;

- inspect the pulley and assess the condition of the belt.

Is the belt still on the pulley? This means the problem with the stalled drum isn't the drive. If the rubber has come off, carefully inspect it and the wheel for defects. If there's no damage or stretching, you can reinstall the rim; otherwise, you'll have to replace it with a new one.

A new drive belt is selected taking into account the serial number of the Siemens washing machine.

If the belt slips for the first time and remains intact, there's no need to worry. Simply tighten the rubber band and run a test cycle. However, if slippage occurs repeatedly, it's a different matter: then you need to move on to the rubber element or pulley repair. In the latter case, proceed as follows:

- we fix the wheel motionless by clamping a screw or stick between the blades;

- We pour WD-40 lubricant on the central bolt and wait 15-40 minutes for the product to “work”;

- Using a suitable ratchet, loosen the bolt (do not apply force, otherwise the thread will strip);

- remove the wheel from the shaft;

- we buy a new pulley;

- We secure the new pulley on the shaft by tightening the central screw.

The drive belt is installed on the new pulley. First, we place the rubber band around the motor shaft, and then we pull it onto the drum pulley. The new rubber band will be very tight, so be prepared for this.

There is something foreign stuck in the tank.

A foreign object stuck in the machine may be the reason for the drum stopping suddenly. Keys, coins, and hairpins that get into the washing machine can fall into the drum, get caught in the hole in the container, and cause the shaft to jam. Eventually, the Siemens will grind to a halt. A jammed drum is a serious matter. Attempting to manually unscrew the drum or restart the wash cycle will lead to serious consequences: mechanical damage and deformation of both drums.

Before washing, check the pockets of items loaded into the drum - forgotten items can cause jamming and clog the drain.

To free the drum, you need to remove the stuck object from the tank. The easiest way to do this is through the heating element opening, especially if the heating element is located near the back wall. What should you do?

- Disconnect Siemens from the power supply.

- Shut off the water supply.

- Drain the water through the emergency drain or the waste filter (if the washing machine stops during the wash cycle).

- Detach the back wall from the housing.

- Find the heating element under the tank, or more precisely, its rounded connector with wires connected to it.

- Take a photo of the location of the wires.

- Disconnect the terminals.

- Loosen the center fastener.

- Remove the heating element (if it is stuck, use WD-40).

- Use your hand or a bent piece of wire to remove the stuck object through the resulting hole. At the same time, remove any debris accumulated at the bottom of the tank.

If the heater is located near the front panel of a Siemens machine, it's recommended to remove the stuck object through the drain hole. Simply lay the machine on its side, unscrew the drain pan, release the drain pipe, and fish out the "lost object" by hand.

Drum flaps in a top-loading machine

Owners of Siemens top-loading machines may encounter another cause of drum stalling: doors that open during a wash cycle. The doors swing open and become stuck, locking the entire mechanism. This type of malfunction is impossible to resolve on your own; a professional repairman is required. If your top-loading machine stops with a clanking sound, you should:

- immediately de-energize the machine;

- collect spilled water;

- call service.

Siemens vertical models may stop during washing due to the drum flaps being open.

Trying to return the drum to its proper position on your own can damage the cylinder or tub. Only a professional can disassemble the washing machine, clear the jam, and return all components to their proper positions.

Let's pay attention to the engine

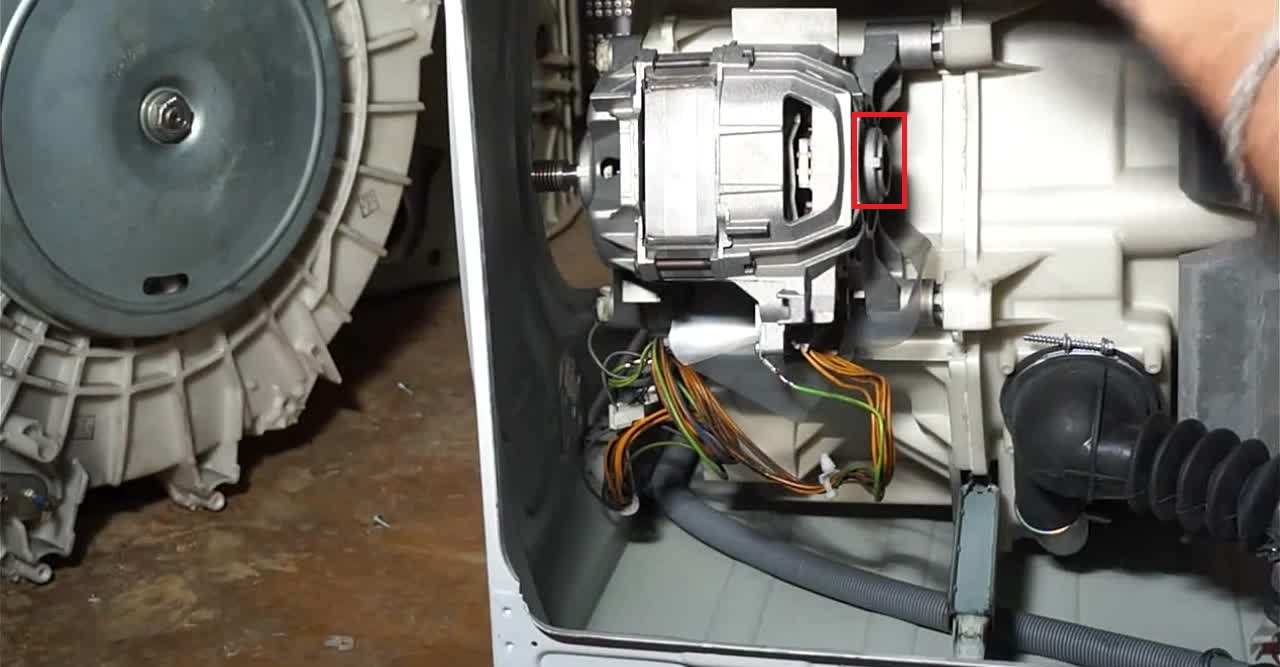

The drum also stalls when there's a problem with the motor. The motor won't accelerate, and the shaft, like the cylinder, remains motionless. The collector motor is the most common cause of failure, as these devices are prone to several common faults:

- worn out electric brushes;

- peeling lamellas;

- winding break.

Diagnosing and repairing the motor is not an easy task. First, the motor must be removed from the washing machine. Second, it must be tested for proper operation using a multimeter. It is important to act sequentially: first, check the general condition of the motor, then measure the length of the carbon brushes, inspect the lamellas and “ring” the winding for breakdown.

Replacement components are selected depending on the serial number of the existing Siemens washing machine.

If you suspect a motor failure, we recommend contacting a service center. While you can replace the brushes yourself, testing the motor itself, grinding the fins, and repairing the windings should be done by professionals. Sometimes repairs are futile—the only solution is to replace the motor.

Electronic failure

Worse, if the drum stalling is caused by a control board failure, this type of malfunction is more difficult to diagnose and more expensive to repair. Self-repair is not recommended – inspection and testing of the electronic unit should be performed by a specialist. There are several compelling reasons to contact a service center:

- special equipment is required for diagnostics and reflashing the board;

- the work will require skill, experience and a lot of time, since it will be necessary to sequentially check each element of the module;

- One wrong move can lead to permanent damage to the board, which is expensive.

It's almost impossible to immediately determine that the problem is with the board. The entire module, or the element responsible for communication with the motor or drive, could burn out. A millimeter-long break in the track or a single burned-out triac will interrupt the circuit: the unit won't receive the command and will remain motionless. Upon detecting a lack of response, the system will automatically stop the washing machine.

The cost of a new control board can range from $50 to $250, depending on the model of Siemens washing machine.

It's strongly recommended that you don't attempt to repair the control board yourself. If no problems with the drive, motor, or drum are detected, it's time to contact a service center.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Thank you