The spin cycle of my Zanussi washing machine isn't working.

It's easy to tell that a Zanussi washing machine isn't spinning: after the wash and rinse cycles, the machine will suddenly freeze and stop responding to user commands. Before the stop, there's no indication of a problem: the program will start, the drum will spin, and water will fill and drain. But you won't be able to spin the clothes, as the system will obviously malfunction and deliver wet items.

It's easy to tell that a Zanussi washing machine isn't spinning: after the wash and rinse cycles, the machine will suddenly freeze and stop responding to user commands. Before the stop, there's no indication of a problem: the program will start, the drum will spin, and water will fill and drain. But you won't be able to spin the clothes, as the system will obviously malfunction and deliver wet items.

Ignoring the problem is a bad idea – you need to immediately begin checking and repairing your washing machine. Now it's time to figure out the correct procedure and what to look for.

What malfunction "disabled" the spin?

The lack of spin on Zanussi washing machines does not always indicate serious problems. Sometimes the problem is simply due to user inattention or a slipped drive belt, and the situation can be corrected in a couple of minutes. However, there are more serious reasons for hanging after rinsing:

- the tachogenerator (Hall sensor) burned out;

- the electric brushes are worn out;

- the motor winding is damaged;

- the thyristor responsible for the motor or the entire control board as a whole has failed.

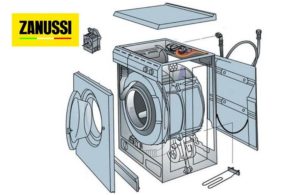

The spin cycle on a Zanussi may not work due to problems with the motor, drive belt, and control module.

To diagnose a washing machine, you need to check all possible problems sequentially. It's best to start with the simplest step—ruling out user error—and finish by diagnosing the control board. Let's look at each step and instruction in more detail.

The owner of the car got something mixed up.

First, check to see if a user error occurred when starting the wash cycle. It's likely that a program was initially selected that doesn't include a spin cycle. Several Zanussi cycles, such as "Delicates," "Hand Wash," "Shoes," "Wool," and "Outerwear," always end after the rinse cycle—this is factory default. It's worth checking the display with the selector or recalling which cycle was started. If there was a mistake, you can restart the machine with the correct settings.

Another possible issue that can cause the spin cycle to fail is a forced disabling of this option. Some Zanussi models feature a special button that operates on the "old" spring mechanism. If the button was previously pressed, the spring doesn't always return to its original position after the cycle ends, even after the system is turned off. Most likely, it remains activated and automatically disables the spin cycle for each subsequent program.

The spin stop button on your Zanussi may still be activated after the previous wash – check if it is pressed!

If the mode is selected correctly and the spin cycle has not been switched off, then the drum needs to be checked. Modern washing machines have a built-in imbalance control function. When a user overloads or underloads the machine, the system detects an imbalance as the spindle spins and terminates the cycle for safety. The same applies to clothes that have bunched up during the wash cycle, posing a risk to the machine. The instructions for "rescue" are simple: open the door, straighten the items, remove the excess, or add the missing kilograms.

Drive mechanism or speed sensor

If the cycle is set correctly and imbalance is ruled out, then there's a problem. It's likely that one of the components responsible for rotating the motor and drum has failed and requires diagnostics, repair, or replacement. There are several possible culprits, so you'll need to check each suspect, from the simplest to the most complex.

The simplest problem is with the drive belt. The connection to the motor is obvious. The drive belt is what transmits the speed from the accelerating motor to the drum shaft, which is necessary for the drum to rotate during a full spin cycle. If the belt slips off the pulley or breaks, the motor spins idle and the machine itself remains stationary. The system detects the discrepancy, freezes, or stops the cycle, dispensing wet laundry. Checking the condition of the drive belt is easy if you follow these instructions:

- de-energize the equipment;

- turn off the water;

- turn the technique around;

- remove the back wall by unscrewing the screws around the perimeter;

- find the belt (the rubber band should be stretched on the pulley wheel; if the tension is too weak or the rim has come off, then the “ring” needs to be changed).

To change the belt, remove the old one and purchase a similar new one. Then, attach the rubber band to the small wheel and try to tighten it onto the large wheel while simultaneously turning the pulley. Be prepared for the fact that you will have to put in a lot of effort and skill.

A tight and intact belt will clearly indicate there are no problems. Then, you should check the tachogenerator—a sensor shaped like a ring with a wire attached. It's mounted on the engine and records the engine's RPM. If the device fails, control over engine acceleration is lost, the control board can't monitor the drum's rotation, and for safety reasons, it shuts down the system.

The tachometer sensor diagnostics are carried out as follows:

- After disconnecting the power from the washing machine and turning it over, unscrew the screws and remove the back wall;

- unhook the drive belt;

- we find the engine located under the tank;

- unscrew the bolts holding the motor;

- we rock and remove the engine from its mounting place;

- carefully disconnect the sensor from the housing;

- We begin to “ring” the tachometer (we attach the multimeter probes and measure the resistance on the contacts).

The working tachometer sensor is returned to its place, and the burned-out one is replaced with a new one. The device cannot be repaired, and its cost is relatively low, ranging from $5 to $12.

Is the motor or the electronics to blame?

Next in line for inspection is the electric motor. More precisely, the graphite brushes attached to its housing. These are two small casings containing rods with carbon tips. When the "carbons" wear down and become smaller than 1.7 cm, the frictional force emanating from the motor is not sufficiently dampened, sparking and overheating begin.

To check the condition of the carbon brushes, unscrew the screws holding the housings, pull out the rods, and measure the length of their tips. If they are too short, remove them and install new ones. It's important to always replace the brushes in pairs, even if one is not completely worn.

The second step is to check the winding. It doesn't break down often, but there's always a risk, and symptoms of damaged wiring include a lack of spin on the washing machine. To test, place one multimeter probe on the wire and the other on the motor housing. The difficulty is that you'll have to test each wire. If a breakdown is detected, it's best to forego costly repairs and buy a new motor immediately.

If the motor, tachogenerator, winding, and brushes are all in order, the only remaining option is a faulty control board. It's best not to attempt home diagnostics here. The fact is that checking and repairing Zanussi electronics on your own is too risky. It's better not to experiment, but to immediately contact a service center for professional help.

A washing machine that's not spinning isn't a cause for panic. In most cases, the problem isn't a serious breakdown, but rather user inattention or some other simple malfunction. Many problems can be solved at home, as long as you follow safety precautions and follow the instructions.

Interesting:

2 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Hello! Could you please tell me if my washing machine has two spin modes, short and long? On the short setting, it goes into spin mode, but on the long setting, it mostly stays put (it rarely spins and that's it). It's an old Zanussi with a spring.

I have the exact same problem: the short one squeezes, and sometimes the long one does the same. Where can I find a solution? Can anyone answer?