How to lubricate a bearing on a Candy washing machine

When a bearing assembly starts making unusual noises during a wash cycle, it's a sure sign that it's about to fail. To prevent an impending malfunction, it's important to respond promptly to this signal. As a preventative measure, we recommend partially disassembling the machine, removing the bearings, lubricating them, and then reinstalling them. However, this entire process isn't easy and takes a considerable amount of time, so it's best to try lubricating the bearings in your Candy washing machine. This will save both time and effort, and we'll share a method that will help you accomplish this task.

When a bearing assembly starts making unusual noises during a wash cycle, it's a sure sign that it's about to fail. To prevent an impending malfunction, it's important to respond promptly to this signal. As a preventative measure, we recommend partially disassembling the machine, removing the bearings, lubricating them, and then reinstalling them. However, this entire process isn't easy and takes a considerable amount of time, so it's best to try lubricating the bearings in your Candy washing machine. This will save both time and effort, and we'll share a method that will help you accomplish this task.

The easiest way to fill a bearing with grease

Some professionals use this unusual method, which allows them to lubricate bearings without disassembling the drum of an automatic washing machine. The main advantage of this method is that repairs can be carried out without touching the drum or other key components of your "home helper." To do this, you'll need:

- disconnect the equipment from communications;

- move the unit away from the wall to make it easier to access;

- Unscrew all the screws that hold the back panel of the device;

- remove the drive belt;

- wedge the drum pulley using a metal rod;

- unscrew the retaining bolt;

- pull the pulley off to access the outer bearing;

- select a spot directly above the bearing and, stepping back from the edge about 7 millimeters, mark this area with a pencil or marker.

It is important to note: this repair method is only suitable if the bearings are not damaged; in other cases (corrosion or deformation of the bearing races), replacement will have to be carried out using the traditional method!

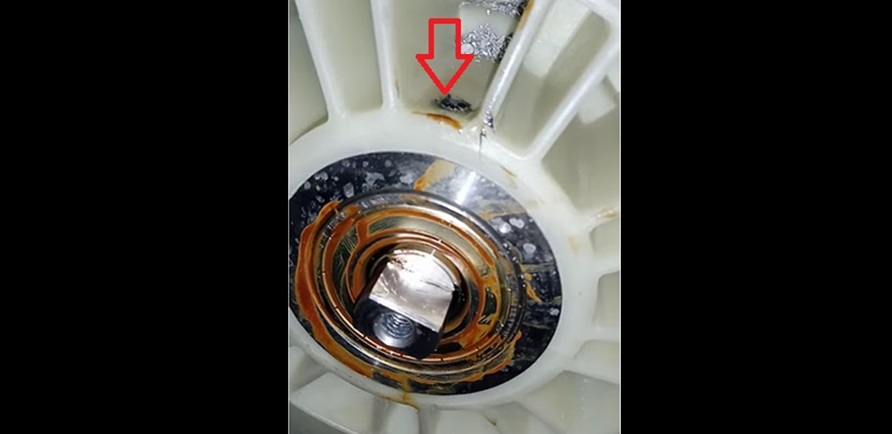

After completing the above steps, you'll need to drill the designated area using a drill with a 5mm metal drill bit. This will create a hole in the plastic and the bearing races. You'll know you've started drilling when you see the telltale metal shavings. It's crucial to generously coat the resulting hole with grease.

Next, you'll need to manually rotate the drum back and forth approximately 50 times. This rotation will allow the cleaning agent to better distribute within the bearing assembly. Next, add the cleaning agent to the hole, but less than the first time. Then, rotate the drum again, stopping only when the strange sound from the bearings completely disappears. This will indicate that the part has been fully restored.

It is important to use the correct composition

Whether you're disassembling the tank or not, you'll still need high-quality bearing grease. There's usually a wide range of options, so it's easy to make the wrong choice. To avoid this, pay attention to the key qualities of the product.

- Water resistance. Bearings are fitted with a seal that rotates quite actively on the shaft. This prevents water from penetrating the unit. Therefore, the lubricant on the sealing ring should remain on the bearing for as long as possible, rather than being washed away by water after a couple of operating cycles.

- Heat resistance. This quality is important not only because washing machines heat water to 90 degrees Celsius, but also because the high rotation of the drum causes the shaft to heat up very quickly, along with the bearings and seal. If the material isn't heat-resistant, it will degrade over time, allowing water to enter the bearing assembly.

- Non-aggressive. Choosing a high-quality, non-aggressive lubricant prevents the seal from becoming soft. It also prevents it from becoming too hard and therefore leaking.

- Thickness. The detergent must have a thick consistency. This is important to prevent it from leaking during washing.

When choosing the right lubricant, keep one more important detail in mind. In this work, you cannot use substances intended for lubricating cars, as they are not suitable for washing machines. Therefore, there is no need to use products like Azmol or Litola-24.

When it comes to specific brands, it's very difficult to understand them without some background. Therefore, we've compiled a short list of lubricants that have proven themselves to be highly reliable. These include the following:

- AMPLIFON is a waterproof product from Italy, manufactured by MERLONI;

- Anderoll is a special lubricant recommended by Indesit. It's available in stores in either 100-gram jars or special syringes. This amount is enough for two restoration procedures;

- LIQUI MOLY "Silicon-Fett" is a silicone-based lubricant from Germany. It comes in 50-gram tubes. It's expensive, but it delivers effective results.

- Huskey Lube-O-Seal PTFE Grease is another high-quality technical product. It offers excellent moisture resistance and performs exceptionally well on bearing assemblies.

All of the above products are safe to purchase for DIY repairs of your "home helpers." Use only high-quality lubricant and follow our instructions. If you don't want to drill anything, partially disassemble your washing machine.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment