How to remove the outer race of a washing machine bearing?

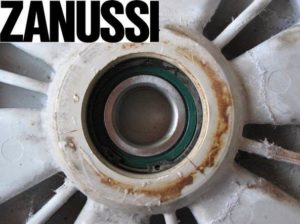

Sometimes removing a bearing's outer race is very difficult: the outer "shell" rusts, deteriorates, and becomes permanently welded to the shaft. Standard methods for removing the stuck ring are impossible, and drastic measures like knocking it out and sawing it off risk irreparably damaging the unit. There is a solution: rely on more "civilized" and safer methods.

Sometimes removing a bearing's outer race is very difficult: the outer "shell" rusts, deteriorates, and becomes permanently welded to the shaft. Standard methods for removing the stuck ring are impossible, and drastic measures like knocking it out and sawing it off risk irreparably damaging the unit. There is a solution: rely on more "civilized" and safer methods.

Auxiliary techniques

Removing a rusted bearing is much more difficult—everyone knows that. Obviously, the element will have to be removed piece by piece, risking the bearing crosspiece and the drum. But you can knock the outer race off the washing machine drum shaft with less damage if you make the task easier beforehand. Two methods will work well: treatment with an anti-corrosion agent and local heating.

First, the seized bearing and the entire mounting surface should be thoroughly treated with a specialized cleaner. WD-40 is only used as a last resort, as it's relatively weak. It's better to use products with a more active anti-corrosion compound. Among domestic products, NanoProtech Super offers similar results, while CycloFusion 3.0 is a Western alternative. Both lubricants are excellent rust removers, the only difference being the price: the Russian version is half the price.

A seized bearing must be treated with anti-corrosion lubricant - "NanoProtech Super" or "CycloFusion 3.0".

After applying grease, it's recommended to heat the damaged bearing. It's best to apply heat locally to ensure precise heating. A blowtorch won't work; a heat gun or a welder should be used. A heated part will release more quickly from its seat.

How and with what can I remove the magazine?

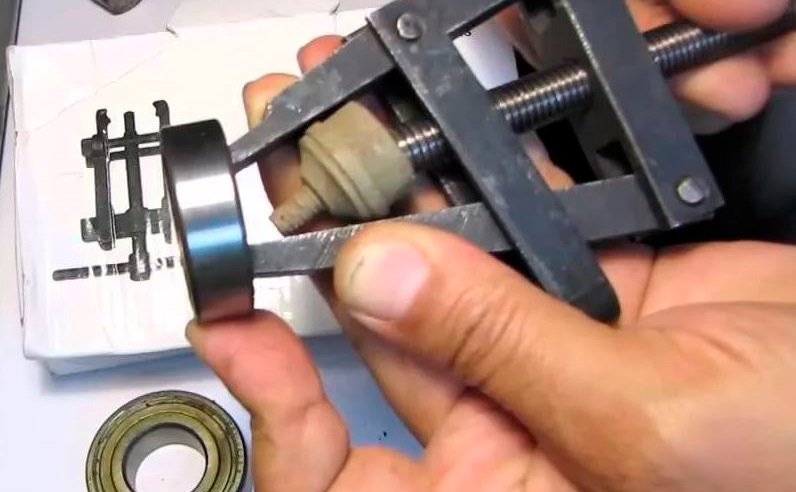

Most often, a damaged bearing is driven out or removed from its seat using a special puller. The latter option is more difficult, as not everyone has access to this tool. It's also not guaranteed that the tool will work and help you remove the part yourself. Therefore, it's better to resort to a more practical and effective method of knocking it out.

But even for knocking out the ferrule, it's necessary to find a suitable tool. Many craftsmen prefer a drift. A curved chisel from a 22-24 mm wrench with one 24 mm end cut off is often used instead. If necessary, the ferrule is locally ground with a Chinese engraver with an abrasive attachment and then knocked out.

There are also clever inventions that greatly simplify the process of knocking out bearings. For example, some people attach a collet with semicircular jaws to the balls and add a spacer. This makes it easier to hit the part with a hammer, ensuring a uniform and precise tapping.

But novice and "casual" repairmen rarely encounter stuck bearings and don't bother making special tools to knock them out. In such cases, it's recommended to use improvised materials. A good example is a section of thick-walled tubing, the diameter of which fits optimally into the opening between the faces of the bearing race. Simply rest the tubing against the outer rim and strike it sharply with a hammer.

Another option is to use electric welding. We weld two protrusions onto opposite sides of the ring, then place a socket extension on them and knock out the bearing. This method has an obvious advantage: the part heats up during welding, making the removal process easier. The key is to have a welding machine and know how to use it.

An experienced craftsman offers another simple, yet effective, method. Here's how:

- generously treat the affected area with WD-40 and leave overnight;

- in the morning we fix a sharpened reinforcement rod 30 cm long to the outer ring;

- we punch the structure with a hammer;

- lubricate the inner race with WD-40;

- we use a grinder to cut holes in the rim as deep as possible (as carefully as possible so as not to damage the seal);

- we place the reinforcement on the rim and, turning it, tap it with a hammer;

- we continue until the clip bursts.

When knocking out a bearing, you must wear glasses and gloves – it’s unsafe!

When knocking out a bearing, it is important to remember your own safety. Work must be done only with gloves and special glasses to protect against metal fragments. Please remember that these parts are very fragile and when tapped they shatter into dozens of small and dangerous pieces.

It's possible to remove a stuck bearing yourself, but the process is complex and time-consuming. If you lack the time, experience, and strength, it's best to avoid experimenting and leave the removal to professionals.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment