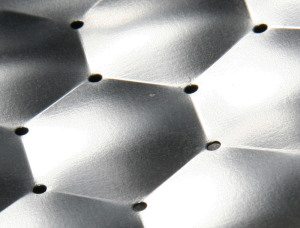

Honeycomb drum in a washing machine

A washing machine not only removes dirt from laundry, it also causes premature wear and tear, and even damage. The degree of damage to fabric depends on what it comes into contact with during washing. A machine with a honeycomb drum is one thing, while a conventional perforated drum is quite another. They have different surfaces, and the friction between fabrics also varies.

A washing machine not only removes dirt from laundry, it also causes premature wear and tear, and even damage. The degree of damage to fabric depends on what it comes into contact with during washing. A machine with a honeycomb drum is one thing, while a conventional perforated drum is quite another. They have different surfaces, and the friction between fabrics also varies.

A regular drum is riddled with holes.

First, it's important to understand what a regular perforated drum, or perforated drum, is. It's a metal or plastic cylinder of a certain diameter, studded with holes. In washing machines with horizontal loading of laundry, such a drum has a back wall, in those with vertical loading – a bottom. Usually the back wall or bottom of the drum is free of holes, but the opposite can also happen.

The holes in the drum are essential for the circulation of water coming from the tank, and they are essential. Engineers calculate the optimal number and area of the holes based on many parameters, including:

- drum rotation speed,

- weight of linen,

- water pressure,

- and others.

The only thing is that the holes are necessary, but they are dangerous for the fabric.

To understand the dangers of having a large number of holes in the side walls of a washing machine drum, you need to understand what fabric is and how it behaves during the washing process.

The fabric rubs against the walls of the drum during washing.

Fabric is a weave of threads, and thread is a weave of fibers. The stronger the fibers and the tighter the weave, the stronger the fabric and the more difficult it is to destroy. For example, fabric made from polymer threads is much more resistant to abrasion than fabric made from natural fibers.

Fabric is a weave of threads, and thread is a weave of fibers. The stronger the fibers and the tighter the weave, the stronger the fabric and the more difficult it is to destroy. For example, fabric made from polymer threads is much more resistant to abrasion than fabric made from natural fibers.

The laundry is loaded, and the washing machine is revving up. The fabric begins to rub against the drum walls, being rinsed with water and diluted detergent. This is the washing process. The fine fibers of the fabric, like a grater, rub against perforated metal. The edges of these perforations aren't sharp, but they are enough to cause significant friction. The fabric begins to slowly wear out. After a few washes, it no longer has the strength it once had. This is especially true for wool, cotton, and other delicate fabrics.

If a thread has come loose somewhere in your underwear, things are even worse. A poorly placed hook in a hole can cause the thread to pull out, ruining the fabric.

Miele engineers solve the problem

Designers at many companies have worked and continue to work on the problem of fabric wear during machine washing. Finding the optimal balance of parameters that will effectively clean clothes while minimizing damage to the fabric is no easy feat. As mentioned earlier, washing primarily involves friction, and it's unavoidable.

Designers at many companies have worked and continue to work on the problem of fabric wear during machine washing. Finding the optimal balance of parameters that will effectively clean clothes while minimizing damage to the fabric is no easy feat. As mentioned earlier, washing primarily involves friction, and it's unavoidable.

Miele engineers, as often happens, began looking for a solution in the environment. They were drawn to the honeycomb. The structure, composed of regular hexagons, even molded from soft wax, proved to be quite stable. Empirical data was confirmed in laboratory tests.

Invented within Miele, the honeycomb drum is a cylindrical metal structure with convex hexagons stamped into it. It has significantly fewer water circulation holes, and their surface area is significantly smaller than in a conventional drum. Liquid remains in the container longer, ensuring both efficient use and effective cleaning of fabrics. Furthermore, the possibility of small, hard objects (sometimes forgotten to remove from pockets) penetrating beyond the drum is virtually eliminated. This protects other components of the washing machine from damage.

To increase water flow in the drum, water intake elements are installed. Surface smoothness, as one of the decisive factors in fabric preservation, is given special attention. The slightest doubt and the drum is sent for rework or rejected. This could be due to a snag in the nylon fabric, which was drawn across the honeycomb.

The honeycomb structure promotes the formation of a thin water film, significantly reducing friction and improving cleaning. Furthermore, the honeycomb structure reduces the contact area between the drum surface and the fabric, which also reduces friction.

Conclusion

The new Miele drum offers significant advantages over traditional designs. This is evident even in the hardest spin mode, where fabrics are not sucked into the holes and require less force to remove.

Therefore, clothes and other items that are usually washed by hand to avoid damaging the delicate fabric will not be damaged in any way in a washing machine with an innovative drum.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment