How to make a metal cutting machine with a washing machine motor?

These days, even the most basic metal cutting machine isn't cheap. Chinese distributors sell mediocre models with a lifespan of a couple of months for $30–$40, to say nothing of high-quality machines that last a long time. But there's no problem that can't be solved with skill and ingenuity. There's a way to build a metal cutting machine using a washing machine motor. Supposedly, the cost of this procedure is minimal, and the results will please everyone without exception. So, let's figure out how.

These days, even the most basic metal cutting machine isn't cheap. Chinese distributors sell mediocre models with a lifespan of a couple of months for $30–$40, to say nothing of high-quality machines that last a long time. But there's no problem that can't be solved with skill and ingenuity. There's a way to build a metal cutting machine using a washing machine motor. Supposedly, the cost of this procedure is minimal, and the results will please everyone without exception. So, let's figure out how.

First, connect the engine

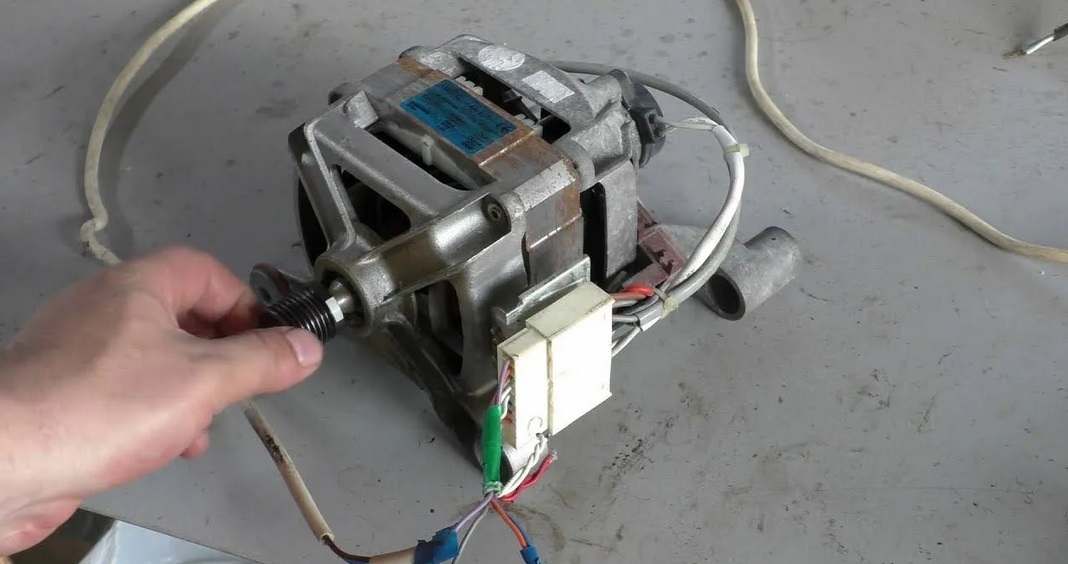

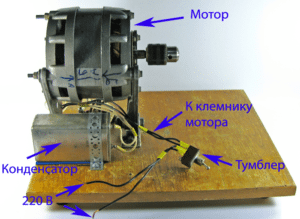

There are several methods, or rather, circuits, for connecting a washing machine motor. The simplest method involves connecting it directly to a power outlet without adding a capacitor or switch. Let's take a closer look at this method.

In short, we need to determine which terminals on the electric motor are the starting and which are the running terminals. By setting up the correct connection combination, you can start the motor. The key is to connect the ends of the starting and running windings into a single wire. For this, you'll need:

- plug;

- three wires with plugs.

Important! Most motors have 5-6 connection terminals. They are numbered accordingly. Regardless of the specific number of terminals, the connection mechanism is identical.

The terminal numbers can be found on the motor housing. If there isn't one, you can use a multimeter to determine the winding type. The starting winding has a higher resistance, while the running winding has a lower resistance.

You need to take a power plug and connect a separate wire with a plug to one end, connected to terminal number 2. Attach a split cable with two plugs to the other end. We want pins 1 and 4 to become a single wire, so we connect the plugs from the split cable to them one by one.

After completing this procedure, try inserting the plug into the socket. If everything was done correctly, the rotor will immediately start rotating. Congratulations, you have successfully assembled an electric motor circuit.

Assembling the machine

So, now we can assemble the working engine and the other parts into a single machine. How do we do this?

- First, you need to secure the motor to the workbench. To do this, take 2-4 metal angles and weld them to the sides of the motor.

- Weld a bolt to the shaft to hold the tool in place. First, I made a few short welds, then welded the bolt itself to minimize runout.

- Now you need to install the disc onto the shaft. Weld the pulley from the grinder extension onto the shaft, and tighten a nut with a groove that matches the inner diameter of the grinder disc. The main thing is that the disc diameter matches the fit.

The resulting machine can work with both grinding, cutting and polishing discs of angle grinders, as well as with sharpening stones.

Cutting machines are quite dangerous, so it's best to think about a casing system, which you can make yourself from sheet metal.

Ultimately, if you have a washing machine motor and all the necessary parts, this machine won't cost you a penny. If you don't have one at home, you can buy a washing machine motor at a salvage yard for 300 rubles. The main thing is that the power of the found motor is not less than 180 W, and the engine is working. Before assembly, check the engine's serviceability with a multimeter.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment