The Beko washing machine drum does not spin.

Unfortunately, Beko washing machines sometimes surprise their users with a non-spinning drum. For no apparent reason, the machine freezes mid-cycle, stopping operation. Sometimes, the drum becomes so jammed that it's difficult to turn even by hand. We'll explore the possible causes of a non-spinning washing machine and explain what to do in such situations.

Unfortunately, Beko washing machines sometimes surprise their users with a non-spinning drum. For no apparent reason, the machine freezes mid-cycle, stopping operation. Sometimes, the drum becomes so jammed that it's difficult to turn even by hand. We'll explore the possible causes of a non-spinning washing machine and explain what to do in such situations.

Why did the drum stop?

To understand why the drum has stopped spinning, you need to analyze how the washing machine operated before the stoppage and run diagnostics. It's important to determine the cause of the malfunction and take corrective action. Typically, the main drum "freezes" in place due to:

- problems with the drive belt or drum "wheel" (the cause may be in the rubber or the pulley);

- a foreign object gets inside the tank. It gets stuck between its walls and the drum and blocks the latter's rotation;

- failure of the engine coil;

- Severe wear of the motor's electric brushes. The carbon rods wear out and cannot fully perform their functions;

- damage to the semiconductor elements of the main control module;

- wear of the motor lamellas.

The list of reasons why a washing machine might not spin is far from exhaustive. Even the simplest washing machine consists of a complex set of components, circuits, connections, and individual elements, the failure of which can cause the drum to stop spinning.

When diagnosing your Beko washing machine yourself, start with the simplest steps, eliminating possible causes one by one. If you encounter difficulties checking individual components, you can seek professional help.

Transmission mechanism

What steps should be taken first? In most cases, the machine Beko The drum stops turning due to problems with the drive belt. Perhaps the rubber seal has broken or come off. If this is a one-time "promotion," then simply buying a new element, removing the back panel of the washing machine, and sliding it over the drum and motor pulley will be sufficient.

If the drive belt comes off regularly even after replacement, you will have to dig deeper to rule out a broken pulley.

A new rubber band that comes off the "wheel" again after a few washes is a symptom of a serious problem. To check for a damaged drum pulley, you need to:

- de-energize the washing equipment;

- turn off the shut-off valve responsible for the water supply;

- pull out the washing machine to access its rear part;

- remove the service hatch or the rear panel (depending on the Beko machine model);

- Inspect the drum pulley (the large wheel). If it's in perfect condition, you can reinstall the drive belt. If there are any defects or deflections on the surface, the wheel will need to be replaced.

- Check the pulley mounted on the motor shaft. If the pulley is deformed or damaged, be sure to reinstall the wheel.

If you notice wear marks, cracks, bends, or other defects on a pulley, it's best not to delay replacing it. In fact, reinstalling a drum wheel is not difficult; even a novice can handle it. All you need to do is purchase a similar wheel, remove the retaining bolt, remove the damaged component, and install the new one. Let's look at the steps in more detail.

- Using a wooden block, block the drum "wheel" from moving. If the wheel is deformed, there's no need to protect it. It's important to preserve the screw and threads during the process, so proceed carefully.

- Apply WD-40 to the center bolt. Wait half an hour for the lubricant to take effect.

- Use a wrench of the appropriate size and carefully remove the screw. Be careful not to apply too much pressure to avoid damaging the bolt and threads.

- Remove the old "wheel".

- Place the new pulley on the shaft and secure it with the mounting bolt.

Experts recommend changing the drive belt at the same time as the drum pulley.

Replacing a wheel is not difficult. It's important not to overdo it, as this can damage the threads. Once your Beko machine repair is complete, check the drum's free rotation by hand, then run a test wash.

Foreign body in the tank

Machine repair technicians tirelessly emphasize the dangers posed by foreign solid objects falling into the washing machine drum. They describe how costly repairs this can be. Despite this, users often forget to check pockets before loading items into the drum and ignore the recommendation to wash bras in special bags. Coins, pins, nails, paper clips, bra underwires, and buttons then become lodged between the drum and the drum.

It wouldn't be such a big deal if the items sat quietly at the bottom of the tank. However, sometimes they can cause the drum to jam and damage the plastic tank. In this case, the entire unit will have to be replaced, which is a rather expensive repair.

If the drum is jammed for this reason, do not try to spin it manually or start the wash cycle. It is important to remove the stuck object from the washing machine drum as quickly as possible. This can be done through the drain pipe hole or the heating element.

If your Beko model's heating element is located at the rear of the drum, this is the best way to access the stuck item. Remove the machine's service hatch, disconnect the power supply from the heating element, loosen the retaining nut, and pull the heating element out. The resulting opening should be large enough to easily remove the object blocking the drum.

If the heating element is located at the front, it's best to avoid trying to remove the foreign object through its opening. This would require removing the front panel of the housing, which is quite difficult. It's much easier to try removing the stuck object as follows:

- drain the water from the system through a debris filter;

- lay the machine gun on its side;

- loosen the clamp securing the drain pipe, disconnect the hose from the tank;

- remove the foreign object through the drain hole.

Once the problem is resolved, check the drum. If it rotates freely, you can reassemble your Beko washing machine and continue using it.

It could also be the motor.

If diagnostics reveal that the drum stoppage is not caused by the drive belt, pulley, or foreign object, the motor will need to be inspected. Inspection should begin with the motor brushes and coil. The procedure is as follows:

- Disconnect the machine from the power supply and close the shut-off valve;

- disconnect the drain and filler hoses from the body;

- lay the washing machine on its left side;

- Take a photo of the wiring diagram to the engine, then disconnect the contacts;

- Unscrew the bolts securing the motor;

- remove the unit from the housing;

- Using a multimeter, check the resistance of the engine coil. If you find that the part is burned out, you'll have to replace it;

- Remove the brushes located on the sides of the motor. If even one of them is badly worn, both need to be replaced.

If the brushes and coil are fine, the drum blockage could be caused by a broken motor wiring or damaged fins. You can determine if the motor is truly faulty by connecting it directly. If the worst is confirmed, the motor will need to be replaced. Repairing it is not advisable, as it is unclear whether reaming the fins or rewinding them will have any effect.

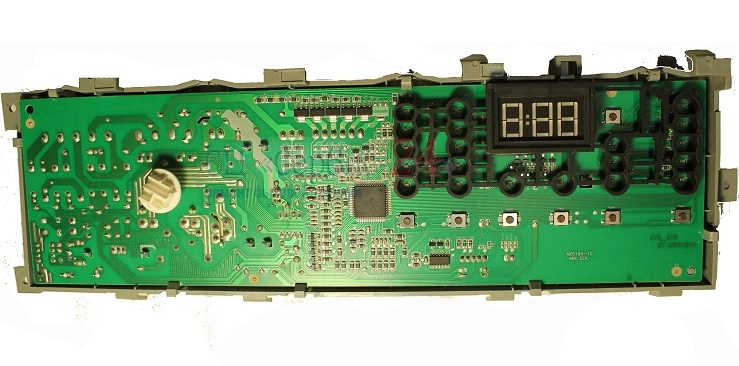

The "electronic" problem

The most difficult situation is when the washing machine drum stops spinning due to a failure of the main control unit. Trying to repair it yourself without the necessary knowledge and experience is not recommended. Only a specialist can identify the cause of damage to the control board and fix it without damaging the equipment. The technician, using special equipment, will correctly test all semiconductors and make a decision on whether repairs are possible or whether replacement of the unit is necessary.

Why is a faulty module considered one of the reasons for a drum stopping? Typically, the cause is burned-out triacs, which control the washing machine's commutator motor. However, this is just one of the details the technician will need to check; in reality, the problem could be something entirely different.

If your primary concern is the washing machine's electronics, it's best to entrust the machine's diagnostics and repair to professionals.

Messing around with the machine's "brains" without the skills and experience can make the situation worse and completely damage the control board. This will significantly increase the cost of repairs.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment