Is it worth buying a washing machine with direct drive?

The inverter motor is the key feature of washing machines produced by Korean manufacturers. Despite the hype, many people are unsure whether it's really worth paying extra for an improved motor or just another marketing ploy. Is a washing machine with a direct drive worth buying? Let's explore this question by comparing collectors and inverters.

The inverter motor is the key feature of washing machines produced by Korean manufacturers. Despite the hype, many people are unsure whether it's really worth paying extra for an improved motor or just another marketing ploy. Is a washing machine with a direct drive worth buying? Let's explore this question by comparing collectors and inverters.

Belt and direct drives

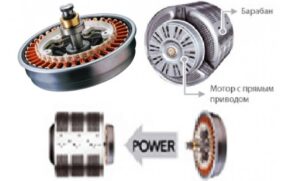

How do direct-drive inverter washing machines differ from commutator-type machines? The key difference is the method of transmitting pulses from the motor to the drum. In the case of inverters, the revolutions are fed directly to the shaft; with collectors, the rotation of the “centrifuge” is started via a drive belt. Let us describe how the process occurs in each situation.

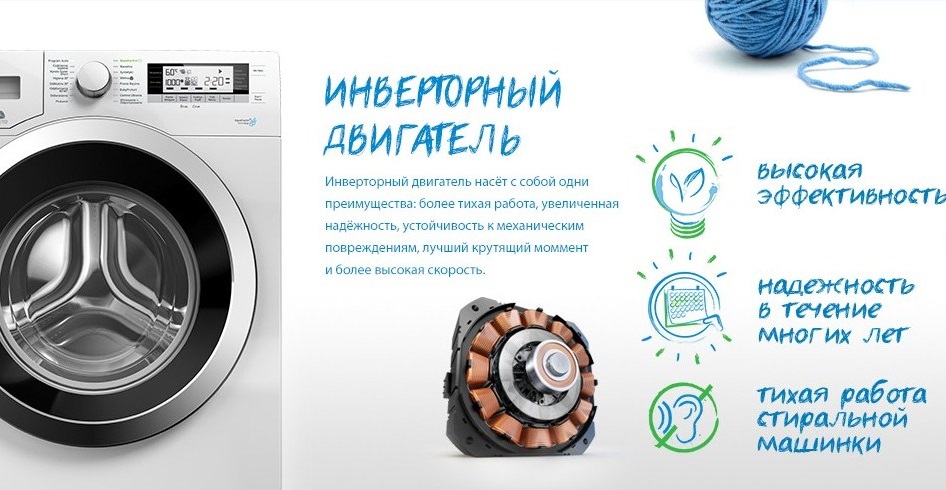

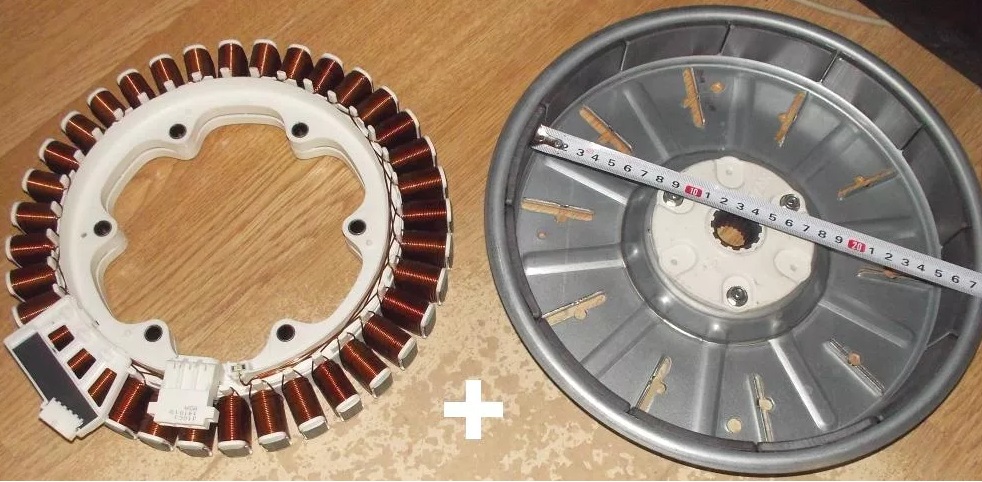

In direct-drive machines, the motor rotor is directly connected to the drum shaft. There is no belt; instead, there is a special clutch. The advantage of an inverter is the absence of brushes, which collector owners must periodically replace.

This technology is called “Direct Drive” – the inverter motor directly rotates the metal tank, without any auxiliary elements.

In direct-drive washing machines, the drum speed is regulated by a control module. Electromagnetic pulses are sent to the motor, starting the centrifuge. Most inverter motors can also sense the weight of the laundry loaded in the machine and automatically adjust their power to the load size.

The drum of a collector-type washing machine is spun by a drive belt. The belt is stretched between the drum pulley and the motor. The belt's elasticity ensures uniform rotation. The speed is controlled by a tachogenerator. Motors of this type also feature graphite brushes to smooth out friction.

So, which automatic washing machine should you choose? Direct drive or belt drive? It's impossible to say for sure which model will last longer without repair. Let's explore the advantages and disadvantages of brushed and inverter washing machines.

Why is this technology being promoted?

It's no secret that every home appliance manufacturer strives to hype their equipment, vividly describe how it outperforms the competition, and sell it at a higher price. Commercials constantly claim that Direct Drive technology is the best solution for any washing machine, while belt-driven units are long overdue. However, the prevailing opinion about cutting-edge washing machines isn't always accurate—they also have weaknesses that suppliers typically keep quiet about.

First, it's worth understanding the advantages of automatic washing machines equipped with a commutator motor. Among the "pros" are:

- low price;

- average trouble-free service life – 15 years;

- Low-cost repairs. The drive belt bears the brunt of the load. If it wears out, simply buy a new belt and replace the old one. The work will take minimal time and money;

- The drive belt can act as a shock absorber when the drum is unbalanced.

It's important to note that belt-driven models have been proven for decades. The vast majority of machines continue to operate without issue for these years. Now, about the "cons" of belt-driven washing machines:

- Reduced tank size. Since the housing also requires housing the drive mechanism, collector-type machines, while similar in size to inverter models, are less capacious;

- The need for periodic motor maintenance. Every 3-5 years, owners must replace the brushes and belt;

- increased noise during operation.

There are no other significant drawbacks. As for commutator maintenance, replacing the brushes and drive belt is quick and usually straightforward. Components are also inexpensive.

What is good about direct drive?

Washing machines with inverter motors have been in production for a long time, so many users have had the opportunity to evaluate their performance. Although these machines are more expensive, they are still popular among buyers. People note several advantages of direct-drive machines.

- Compact body dimensions with a larger drum capacity. Since the machine does not have a belt, pulley, or other parts, the manufacturer can increase the tank, reducing the dimensions of the machine..

- Low noise level. Inverter motors operate quite quietly.

- Increased stability of the washing machine during operation.

- Accelerated washing. The inverter motor runs programs slightly faster, reducing cycle times.

- Reduced energy consumption. This is achieved by removing several elements from the motor-drum circuit. Many inverters can measure the weight of the laundry loaded in the drum and control their power output, which also affects kilowatt consumption.

- Overload diagnostics. Machines with the Direct Drive system will notify the user of an overload. A corresponding error code will appear on the display, or the indicator lights will start flashing. In either case, the cycle will not begin until some items are removed from the drum.

If a collector-type washing machine is overloaded, it will start washing. However, the cycle can end at any time due to a broken belt or a burnt-out motor. Therefore, it's crucial to adhere to the maximum permitted weight and avoid operating the washing machine under excessive loads.

Manufacturers of direct drive machines provide a ten-year warranty on the motor.

Direct-drive machines have many advantages, but it's important to understand that, if well-assembled, even a collector-type washing machine will handle dirt well and be quiet. However, if you're looking for a compact machine with a large drum and minimal energy consumption, an inverter is a good choice.

What's wrong with this technology?

When considering whether to buy a washing machine with an inverter motor, it's best to consider the weaknesses of this type of equipment. There are, of course, some downsides. Among the main drawbacks are:

- high price – this applies to both the washing machine itself and spare parts;

- The need for an uninterrupted power supply. The inverter is controlled by a module that is very vulnerable to power surges. Therefore, it is recommended to install a direct-drive washing machine through a voltage stabilizer;

- Bearing assembly wears out quite quickly. Due to the lack of a drive belt and pulley, the drum bearings bear the entire load from the rotating centrifuge. This causes the bearing rings to wear out and requires periodic replacement;

- Risk of oil seal leakage. With a direct drive, the engine is located directly under the tank. If the O-ring is not replaced promptly, a leak may occur. Water droplets on the motor can cause engine burnout. This type of damage is not covered by the warranty; you will have to finance the repairs yourself.

A simple leak can cause the inverter motor to fail.

Now it's clear what the differences are between direct-drive and belt-drive washing machines. When making a purchasing decision, you should consider all these factors. If you don't want to overpay, you can opt for a high-quality collector-drive washing machine – it will still deliver excellent washing performance. However, don't discount inverters – they can give their competitors a run for their money in some areas.

Interesting:

2 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

With direct drive, the engine is located not UNDER the tank, but to the side of it.

You're writing about the pros and cons of direct drive, while mentioning the pros and cons of an inverter! They're not the same thing.