How does a Zanussi washing machine work?

The internal components of all front-loading washing machines are virtually identical. There are some minor differences, but the general operating principle of the components remains the same. Using a Zanussi washing machine as an example, we'll explain how the main parts interact.

The internal components of all front-loading washing machines are virtually identical. There are some minor differences, but the general operating principle of the components remains the same. Using a Zanussi washing machine as an example, we'll explain how the main parts interact.

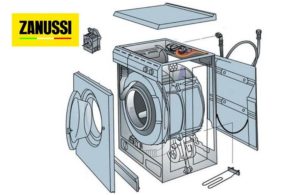

Machine elements and body structure

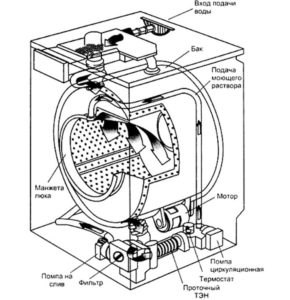

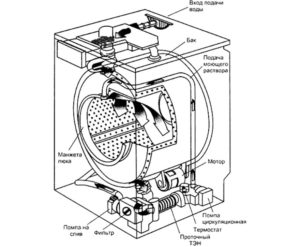

It is not difficult to understand how a Zanussi washing machine works. A description of all the main components and assemblies is provided in the instructions. The wiring diagram is also shown there. The "basic set" of components for an automatic machine is:

- motor;

- tank (depending on the model, it can be metal or plastic);

- drum;

- drain pump;

- electronic module;

- shock-absorbing system (springs, dampers);

- frame;

- pressure switch;

- inlet solenoid valve;

- heating element;

- bearing unit.

Knowing how a washing machine works allows you to diagnose and repair it yourself, without the help of a technician.

If any basic component malfunctions, the washing machine will not be able to perform its functions. Knowing where each part is located and what it does makes it easier to spot any signs of malfunction, diagnose, and repair the machine.

Zanussi washing machines have a distinctive feature compared to other brands' front-loading machines: their body. It disassembles into two halves: the front and the back. Essentially, these machines don't have separate side panels; they are integrated with the front and back panels.

To separate the Zanussi case, remove the plastic plugs on the sides and bottom. These conceal screws, which can be removed. Next, remove the top cover as usual. Underneath are four more screws (two on each side). Once all the screws are removed, the front and back of the washing machine can be easily separated.

What happens inside the case?

If all components and sensors are in good working order, the washing machine operates flawlessly. Each component performs its own functions, and the process is controlled by the main control module, the "brain" of the washing machine. The electronic unit sets the sequence of operations, receives and transmits signals, and ensures uninterrupted interaction of internal elements.

If you disassemble the body of a front-loading machine, the first thing you'll notice is the tank. It's a large plastic container supported by shock absorbers and springs.

The drum is "hidden" in a plastic tank. The "centrifuge" is made of stainless steel and has a porous surface. The tank rotates thanks to a pulley connected via a shaft and a spider. The wheel, in turn, is spun by a motor via a drive belt. The machine actually washes the laundry by increasing its speed.

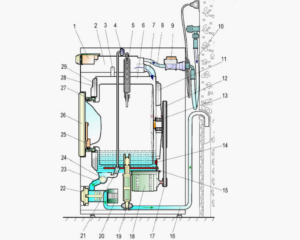

The operating algorithm of an automatic washing machine during a standard wash cycle is simple. After the user selects a mode and presses the "Start" button, the control module opens the inlet valve. Water begins to flow into the system. The pressure switch monitors the filling level of the machine and, when the desired volume of liquid is reached, signals the "brain" to stop filling. The control unit then activates the heating element, whose task is to heat the liquid to the set temperature.

The washing machine's "brain" cycles through the stages and, at the end, commands the pump to drain the water.

This is how every cycle in a washing machine is performed. When additional options are enabled, such as soaking or pre-wash, the program steps change slightly, but the essence remains the same. The control module monitors all components, transmitting prompt "commands" to ensure the machine operates smoothly. To understand the design of an automatic washing machine in more detail, it's necessary to examine each component and part individually.

Interaction of the machine's containers

The largest component of a washing machine is the drum. Zanussi washing machines have a plastic main tank, which helps reduce the final cost. Some models from other brands have stainless steel tanks, which are undoubtedly more reliable, but also significantly increase the cost. The drum is typically installed horizontally in the washing machine. Some models have a slightly inclined drum, but this is rare.

The largest component of a washing machine is the drum. Zanussi washing machines have a plastic main tank, which helps reduce the final cost. Some models from other brands have stainless steel tanks, which are undoubtedly more reliable, but also significantly increase the cost. The drum is typically installed horizontally in the washing machine. Some models have a slightly inclined drum, but this is rare.

The drum contains a porous metal container, into which dirty laundry is loaded. Water first enters a plastic reservoir, where it is mixed with detergent, heated, and then poured through holes into the drum. In addition to the micro-holes, the drum walls are equipped with special ridges, which improve the washing quality.

If you follow all the operating instructions for your Zanussi washing machine, the tank and drum will remain safe and sound. Systematic overloading of the washing machine can lead to damage to the elements. Furthermore, metal objects left in clothing pockets, such as keys, paper clips, screws, and bobby pins, can puncture the tank. A bra underwire caught between the metal and plastic walls can block the centrifuge's rotation.

Heating components

The water in the tank is heated to the user-set temperature by a heating element. The element is located just below the drum, at the rear. To access the tubular heater, you need to disassemble the housing, slide the rear section back, and remove the drive belt.

Heating elements in washing machines are among the most frequently breaking parts.

It's easy to explain why heaters often fail:

- The heating element is constantly in contact with hard water, which is why a thick layer of scale forms on it;

- Limescale causes the heating element to overheat, which leads to the part burning out.

Therefore, to prevent damage to the tubular heater, it's important to install a filter to soften hard tap water at the entrance to your apartment or washing machine. It's also essential to periodically descale the inside of your washing machine using specialized products.

If we talk about the power of the heating elements in Zanussi machines, the elements usually consume 1800-2200 W. Experts do not recommend washing frequently in hot water, as this can lead to premature failure of the tubular heater. If you need to run several cycles in a row with water heating up to 60-90°C, it is important to let the automatic machine “cool down” for 30-60 minutes between washes.

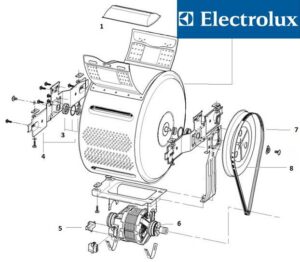

Motor and motor of the machine

The washing machine's drum is driven by an electric motor. The motor transmits power to a pulley via a drive belt, and the wheel accelerates the centrifuge to the required speed. This ensures high-quality washing and excellent spinning. The motor's lifespan depends on several factors, the first of which is the motor type.

Zanussi washing machines are equipped with collector motors.

While collector motors are cheaper than inverter motors, they are inferior to inverter motors in several characteristics. They are less reliable, are sensitive to voltage surges, and require periodic maintenance, including brush replacement. However, if you connect the washing machine to the power grid through a voltage stabilizer and perform regular motor diagnostics, you won't have any problems operating your Zanussi.

While collector motors are cheaper than inverter motors, they are inferior to inverter motors in several characteristics. They are less reliable, are sensitive to voltage surges, and require periodic maintenance, including brush replacement. However, if you connect the washing machine to the power grid through a voltage stabilizer and perform regular motor diagnostics, you won't have any problems operating your Zanussi.

The motor is considered the "heart" of the washing machine. It starts working immediately after the wash cycle starts. Depending on the selected mode, the "brain" regulates the motor speed, sometimes slowing it down, and during the spin cycle, commanding it to accelerate to full speed.

The weak point of commutator motors is the brushes. Over time, after about 4-5 years, the carbon rod wears down, requiring replacement. Installing new brushes is easy, and you can do the repair yourself without calling a professional.

Control board

The user sets the desired washing parameters by pressing buttons on the control panel. The desired mode can be selected by turning the selector knob, additional functions can be activated, and the temperature and speed can be adjusted. The control panel is linked to the main electronic module.

The user sets the desired washing parameters by pressing buttons on the control panel. The desired mode can be selected by turning the selector knob, additional functions can be activated, and the temperature and speed can be adjusted. The control panel is linked to the main electronic module.

The Zanussi main control board consists of semiconductor components: a microcontroller, triacs, capacitors, triggers, thyristors, and resistors. Communication with the machine's main components and assemblies is accomplished via conductive tracks.

Modern Zanussi machines can independently diagnose problems, identify system faults, and notify the user of any malfunctions.

It is the control board that ensures the sequential execution of cleaning programs. All available washing algorithms and parameters are pre-recorded in the electronic module circuit. This gives the user the ability to launch the required mode without errors using the dashboard.

Some washing programs are performed strictly according to the algorithm stored in the "intelligence." Some modes can be adjusted, including changing the water temperature and spin speed.

Other components of the Zanussi washing machine

To fully understand how a Zanussi washing machine works, it's worth considering the additional parts included in each model. Although these components are considered "secondary," they are essential for proper operation. What are these components?

To fully understand how a Zanussi washing machine works, it's worth considering the additional parts included in each model. Although these components are considered "secondary," they are essential for proper operation. What are these components?

- Door seal. This seal is used to seal the washing machine. The rubber seal fits over the outer edge of the drum and the body.

- Shock absorbers. They are necessary to suppress vibrations emanating from the rotating drum. Without springs and dampers, the machine would bounce around during every wash.

- Door locking device. This is a safety mechanism that securely locks the door. Once the lock is activated, the washing machine cannot be opened accidentally.

The washing machine will not start filling the tank with water until the door lock is activated.

- Drive belt. Without it, the electric motor can't spin the drum. The motor transmits impulses through the rubber belt to the pulley, which accelerates the centrifuge to the required speed.

- Counterweights. These are heavy concrete blocks that provide stability to the washing machine. The weight of the stones allows the washing machine to withstand even the fastest spinning drum. Without these weights, the machine would constantly wobble during washing, causing damage to the frame and some of the internal components.

- Door. Without a hatch, it would be impossible to put laundry into the machine.

- Powder dispenser. The detergent drawer is divided into three sections. Water first passes through the tray, mixes with the detergent, and then flows through the pipes into the tank.

- Hoses. They are the washing machine's "circulatory system." They circulate water throughout the machine. Hoses connect the dispenser to the tub, the pump to the drum. If the hoses become clogged, the machine may stop working.

In reality, there's nothing complicated about the design of an automatic washing machine. Difficulties may arise with repairing the control board. Working with electronics does require some experience and knowledge. Otherwise, you can repair the machine yourself. Knowing which components are responsible for what makes it easy to identify the cause of the problem and try to fix it.

Interesting:

2 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

It was very interesting and useful. Thank you!

Thank you.