The dryer drum does not spin.

The design of a modern dryer is very similar to that of a washing machine. They share a similar appearance, control panel, large drum hidden behind a door, and much more, making these two "home helpers" very similar. Even many of the problems these appliances experience are similar. For example, a common problem is when a dryer won't spin, rendering it ineffective. This also happens quite often with washing machines. Let's take a closer look at this annoying problem and how to solve it.

The design of a modern dryer is very similar to that of a washing machine. They share a similar appearance, control panel, large drum hidden behind a door, and much more, making these two "home helpers" very similar. Even many of the problems these appliances experience are similar. For example, a common problem is when a dryer won't spin, rendering it ineffective. This also happens quite often with washing machines. Let's take a closer look at this annoying problem and how to solve it.

The engine failed

If you notice that your dryer drum is spinning slowly, the first thing you need to do is stop the current cycle and remove all clothes from the chamber. When there is no laundry left in the machine, you will need to manually spin the drum in different directions. If it spins as usual without any problems, then everything may not be as bad as it seems at first glance. If unusual noises appear during rotation, or the drum only spins with effort, it's best to stop handling the equipment as quickly as possible to avoid further damage.

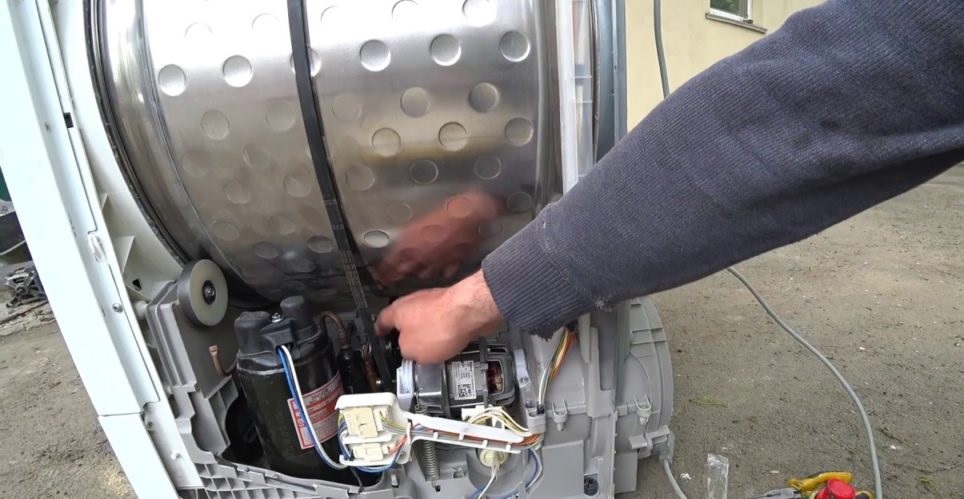

There are several reasons why the drum may slow down. The most common is motor failure. The electric motor, along with the belt drive, is what powers the drum, so if this part fails, there's no mechanical energy.

There are models of drying machines that have a direct drive without a belt.

If the electric motor fails, there are problems with the winding, or the brushes are worn out, the drum may rotate slightly, as if the machine is unsuccessfully trying to restart the drum. However, sometimes even these small attempts will fail if the motor is severely damaged. An inspection of the unit may reveal that either a complete motor replacement or replacement of the worn brushes is necessary.

Not every service center will repair brushes, preferring to replace the damaged motor entirely. This approach guarantees a full restoration of your dryer's functionality, but it requires a significant financial investment. This is because a new motor often costs around 30% of the dryer's total price, plus the cost of replacement, which varies by service center, must be factored in. Repairing the unit is also possible, but it's not always practical, and not every private repairman will undertake it.

Drive mechanism

The belt in the system is directly responsible for directing mechanical energy from the electric motor to the dryer shaft, which, in turn, rotates the drum itself. This is why if the belt is damaged or deformed, there will be no rotational energy, which means that the shaft and drum will not rotate. In this situation, you can conduct your own diagnostics and then share this information with a repair technician. Listen to the appliance's operation—if you hear the sound of an electric motor during drying, there's a good chance the belt is at fault. If the cycle is completely silent, the problem should be looked for elsewhere.

When a belt is torn or stretched, it's easy to simply buy a new one and install it in its place. This procedure isn't complicated or expensive, as belts don't cost much. However, in rare cases, belt deformation and slippage can be caused by a much more serious issue: damaged bearings. In this case, the user may hear a loud whistling noise, static, or other unusual, unpleasant sounds while the equipment is running.

If the belt itself, rather than the bearings, is the culprit, you should carefully monitor the replacement process. Purchase only the original part that will fit your dryer, not a cheap Chinese knockoff. If you call a repair technician, ask them to unpack the spare part in front of you so you can be sure they're not installing a cheap knockoff that might last a month at best. If a private technician tries to install an unmarked part of unknown origin, it's best to decline their services, as they could be costly to your appliance. Genuine dryer parts are sold in appropriately labeled packaging, making it easy to identify a quality part that's safe to install.

Speed sensor

The drum may also spin slowly due to a damaged tachometer. This component controls the drum's rotation speed and then transmits information to the dryer's control board. If the sensor is broken, the control module simply won't know whether the drum is capable of rotating and won't attempt to force it to spin.

If the tachometer fails, it cannot be repaired and will need to be replaced. Fortunately, this repair is considered inexpensive, rarely costing even 20% of the dryer's purchase price. However, be aware of both high and low replacement prices from a private repairman, to avoid having a cheap Chinese tachometer installed instead of the original spare part.

Problem with the bearing unit

Let's return to the situation where broken bearings are to blame for the problem, which is considered one of the most serious causes of the malfunction. If this is what happened, then either a complex replacement of the damaged components or the installation of a completely new tank will be required. Most often, bearings fail gradually, which can be noticed early by a strange sound during the operating cycle, occurring just before the drum comes to a complete stop. If you've heard a loud metallic whistling sound during operation before, your model is likely equipped with a heat pump, so this is considered normal. However, if this hasn't happened before, the unusual sounds indicate a problem with the bearings.

Despite the complexity of the breakdown, there's no need to worry, as any service center technician can quickly disassemble the machine and restore it to working order. If your "home helper" has a detachable tub, the technician will only be able to replace the damaged bearings. If the machine has a molded plastic tub, the entire tub will have to be replaced. The latter scenario is very frustrating, as a new tub often costs as much as 70% of a new dryer, plus the cost of the technician's services should not be forgotten. This is why it's often recommended to simply buy a new unit to avoid the hassle of old spare parts.

It's also worth considering that many service centers refuse to replace bearings because manufacturers require replacing the entire dryer drum. Because of this, users often turn to private repairmen who are willing to replace bearings even in molded plastic drums, which are cut into two equal halves and then joined with bolts and sealant. While this homemade repair may provide a temporary fix, it's best to avoid this questionable solution and instead replace the drum or dryer.

The control board is failing

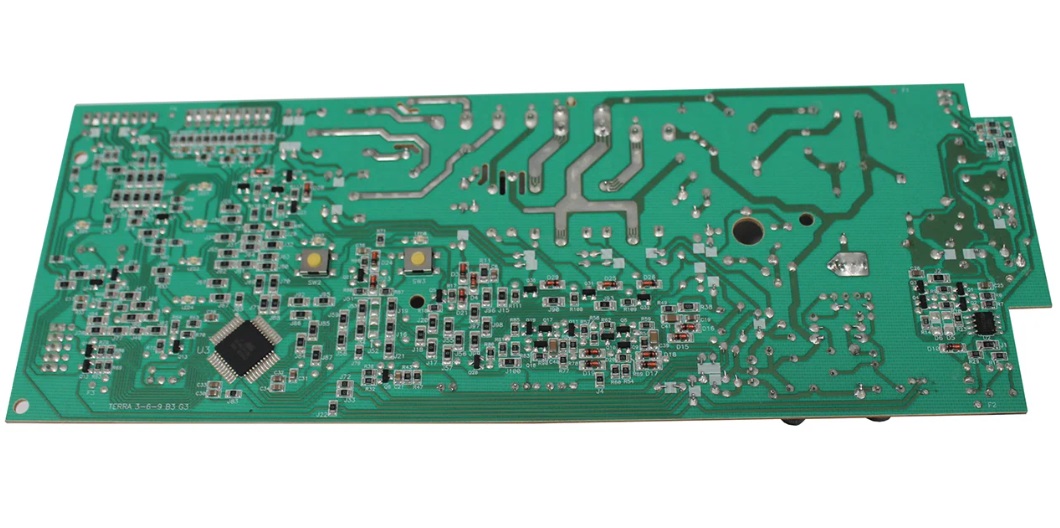

Finally, it's worth addressing the most annoying problem: a faulty control module. These days, all household appliances are smart devices equipped with state-of-the-art sensors and electronic boards that control system operation. When the control board is damaged, the signal to start the drum simply won't be transmitted, even if the drum itself and other key components of the dryer are working properly.

Control board failures can be divided into hardware and software. Hardware-related issues require manual intervention, replacing and repairing small components on the component itself, hidden within the dryer's body. In rare cases, the board cannot be repaired and can only be replaced. If this is your situation, you should consider purchasing a new dryer, as the control module is often even more expensive than the drum, so purchasing a new appliance would be more cost-effective. Software-related issues are much easier to resolve—a technician simply needs to update the software or reset the settings to restore factory settings.

If you decide to repair the module instead of buying a new machine, be sure to check the warranty on the repair, as the component may start malfunctioning again in just a month.

Of course, you shouldn't try to handle electronics yourself; this should only be handled by a service center specialist, who has not only the necessary knowledge but also the necessary equipment. Therefore, if you suspect the control board in your washing machine is faulty, it's best to contact a service center immediately, avoiding the services of private repairmen, who are rarely familiar with complex electronics.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment