What is a tachogenerator in a washing machine?

Sometimes, after taking their washing machine to a service center for diagnostics, owners hear the technician suggest replacing the tachometer sensor. Unsure of what part is involved, people agree to pay an extra thousand or fifteen hundred for the repair. But is the tachometer truly broken, or is the technician just pushing an unnecessary service? Let's explore the function of the Hall sensor and how to check if the part is working properly.

Sometimes, after taking their washing machine to a service center for diagnostics, owners hear the technician suggest replacing the tachometer sensor. Unsure of what part is involved, people agree to pay an extra thousand or fifteen hundred for the repair. But is the tachometer truly broken, or is the technician just pushing an unnecessary service? Let's explore the function of the Hall sensor and how to check if the part is working properly.

Purpose of the tachometer

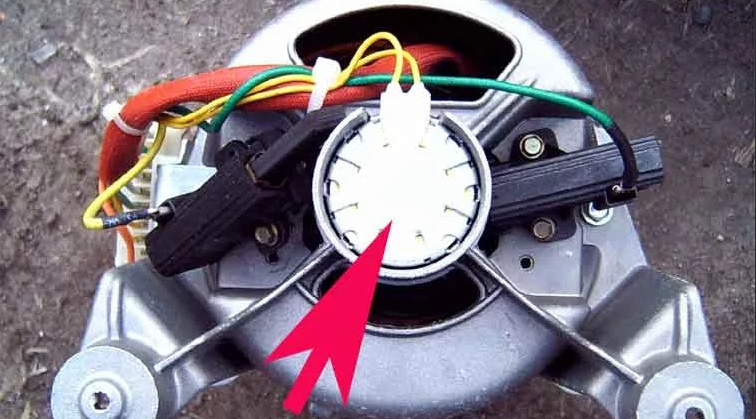

The "heart" of any washing machine is the electric motor. It's what powers the appliance, converting electrical energy into mechanical energy. The tachogenerator in a washing machine is an element that controls the motor speed. The Hall sensor is located on the engine rotor.

The tachogenerator monitors the voltage of the electric current generated by the motor. Thanks to the tachogenerator, all components of the automatic washing machine operate as programmed. If a component fails, the drum will rotate erratically, slower or faster than the settings.

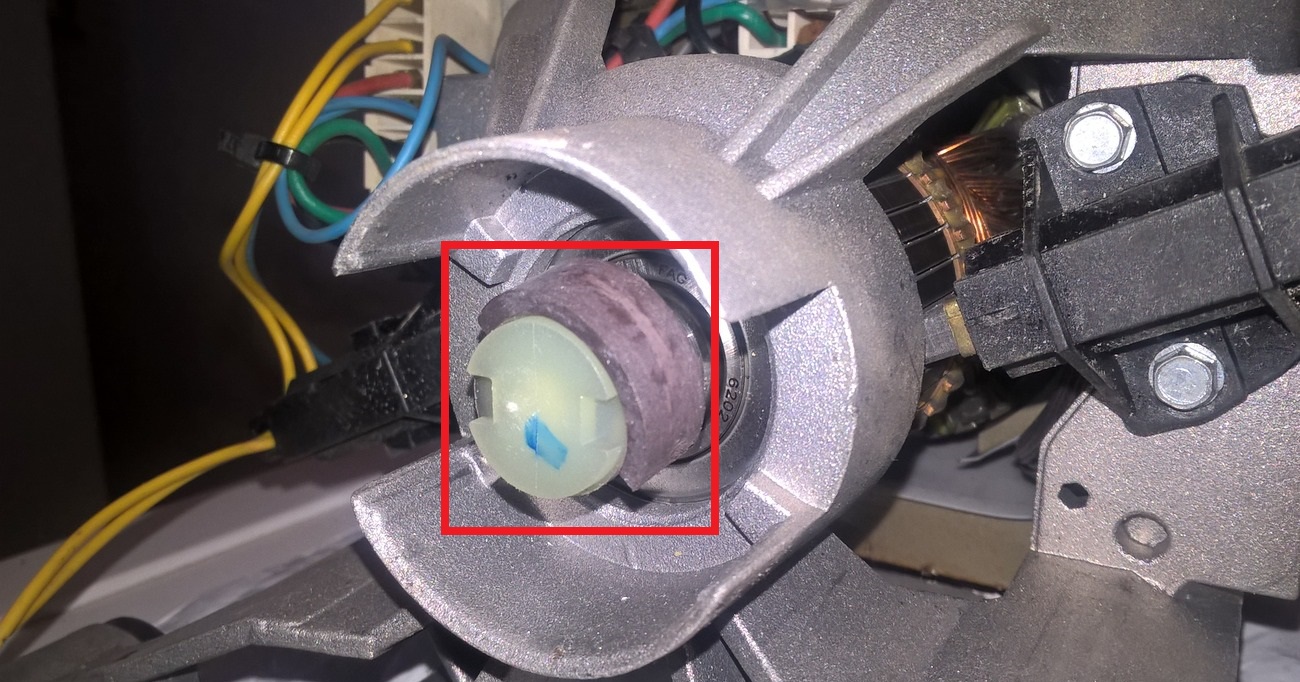

The tachometer sensor is a small metal ring with wires connected to it.

The tachogenerator is easier to find and test in washing machines with commutator motors. Determining which motor your machine has is very simple. Remove the back panel of the housing and check to see if there's a pulley with a drive belt behind it. If so, you're looking at a commutator motor.

If there's no belt drive mechanism, the washing machine is equipped with an inverter motor and a Hall sensor built into the housing. A tachogenerator measures the motor's speed and transmits this information to the main control unit. The data is processed, and the module signals either the speed or the slowdown.

How does a broken tachometer sensor manifest itself?

When the tachogenerator stops functioning, the entire washing machine malfunctions. The washing machine's "brain" doesn't receive information about the motor speed, so it can't control the drum speed during the wash, rinse, and spin cycles. What are the main symptoms of a faulty Hall sensor? What problems can this failure lead to?

- The automatic machine's motor constantly runs at high speeds. This causes strong vibrations within the machine, and noise, humming, and knocking can be heard inside.

- The engine experiences increased load, which is transmitted to both the drum pulley and the shock absorbers. Consequently, these components wear out faster.

- When the motor speed is not controlled, the drum and the entire drive mechanism become unbalanced. This causes the pulley belt to wear out and break quickly.

- Due to the chaotic rotation of the drum, the bearing assembly fails faster.

- In machines with inverter motors, a constantly increasing squealing sound is heard when the Hall sensor fails. In this situation, the drum stops rotating.

- If the tachogenerator breaks down, the washing machine starts to work jerkily and does not start spinning.

Automatic machines equipped with a self-diagnostic system display a corresponding error code on the display if the tachometer sensor fails.

If your washing machine vibrates and hums excessively, then stops running and displays an error code, consult your machine's manual. The error code varies from model to model, so only the user manual can help you decipher the error.

How to properly test a tachometer sensor?

If you suspect that your washing machine has stopped working due to a broken Hall sensor, check the part yourself. Diagnostics of the tachogenerator is performed using a multimeter. The device will help measure the voltage of the element and draw a conclusion about its serviceability.

First, turn on the multimeter and set it to continuity mode. Place the tester probes on the tachogenerator contacts and, with your free hand, spin the motor rotor, no matter which direction. If the meter beeps and the needle on the display oscillates while spinning, the Hall sensor is working properly.

Next, switch the measuring device to voltmeter mode. Set the reading range to 4-5 volts and touch the tester probes to the tachogenerator contacts. Spin the rotor again and observe the values on the multimeter screen. If the tachogenerator is working properly, the voltage generated will be 0.2-2 volts.

If a multimeter test doesn't reveal a faulty sensor, check to see if it's securely attached to the electric motor. A mounting bolt may be loose or the power supply contacts may have come loose. In this case, you'll need to tighten the screw or tighten the wires. You can also use a multimeter to measure the resistance output by the tachogenerator. Normally, the reading should be around 60 ohms. If the Hall sensor shows no activity at all when tested with a tester, the element will need to be replaced.

We replace the faulty part

If you discover that the tachometer is faulty, you'll need to purchase and install a new part. You'll need to purchase components that are suitable for your specific washing machine model. Before starting work, be sure to de-energize the equipment. Next, remove the rear wall of the housing and find the electric motor, and on it, the tachogenerator.

Next, you need to disconnect the Hall sensor contacts and pull it out of its mounting location. You'll need a small, thin screwdriver to remove the element. Once the connectors are disconnected, remove the top cover of the tachogenerator. It may be loose or held in place by several screws.

While disassembling the part, it's a good idea to take photos to avoid mistakes during reassembly and ensure the contacts are connected correctly. Using the photos as a guide, install the new tachogenerator. Then replace the back panel of the washing machine and run a test wash.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment