Types of washing machine motors

The key element in a washing machine is the electric motor: it spins the drum, powering the entire system. Naturally, the motor determines the machine's performance: spin speed, service life, and noise and vibration levels. The more reliable and sophisticated the motor, the longer-lasting, more efficient, and more comfortable the wash. Let's look at the most common types of washing machine motors and how they differ from each other. We'll outline the characteristics, advantages, and disadvantages of each.

The key element in a washing machine is the electric motor: it spins the drum, powering the entire system. Naturally, the motor determines the machine's performance: spin speed, service life, and noise and vibration levels. The more reliable and sophisticated the motor, the longer-lasting, more efficient, and more comfortable the wash. Let's look at the most common types of washing machine motors and how they differ from each other. We'll outline the characteristics, advantages, and disadvantages of each.

The most common electric motor

Of the common motor types, the commutator is considered the most common. More precisely, the motor is called a brush-commutator unit and consists of a moving rotor, a static stator, electric brushes, and fins. The system works due to the sequential reaction on the winding when electric current is supplied. In short, a commutator motor works as follows:

- Electric current is supplied to the graphite brushes adjacent to the lamellas;

- a magnetic field is created;

- through the lamellas, the voltage from the brushes is transmitted to the rotor and stator;

- the rotor begins to rotate, gradually gaining the speed specified by the program;

- the impulse is transmitted to the shaft;

- The washing machine drum is spinning.

The manifold is located at the bottom of the housing, beneath the wash tub. A drive system consisting of pulleys and a drive belt transmits the motor's speed to the drum shaft. As the motor accelerates, the "wheels" spin via a rubber band, transmitting momentum to the drum.

The collector motor is characterized by durability, availability and inexpensive repairs.

The standard commutator motor has a number of advantages:

- simple and reliable mechanism, which makes the engine durable;

- affordable price, which makes the machine cheaper;

- inexpensive and easy maintenance and repair.

The commutator does have its drawbacks. The main one is the high noise level due to the brushes, which constantly wear against the metal motor housing. This leads to a second drawback: the graphite tips wear out over time and need to be replaced.

Asynchronous electric motor

An asynchronous electric motor also consists of a stator and a rotor. The former remains stationary and acts as a magnetic core, while the latter responds to the generated magnetic field, begins to rotate, and spins the washing drum. However, during this process, the motor cannot synchronize with the speed of the magnets and moves slightly behind them. This is where the name "asynchronous" comes from.

Washing machines use two types of asynchronous motors: two-phase and three-phase. Since 2000, the latter have almost completely replaced the former due to their compact size and greater power.

"Asynchronous" have the following advantages:

- simple motor design that rarely fails;

- high maintainability (due to available and inexpensive components);

- low engine cost;

- relatively low noise level.

As for disadvantages, the main one is the large motor size, which precludes the use of asynchronous transmissions in compact and narrow automatic transmissions. Other disadvantages include the need for periodic system maintenance, such as piston lubrication and bearing replacement. Such motors are also not particularly efficient due to their low efficiency and complex electrical circuitry.

Asynchronous electric motors are found only in budget models with low power, small capacity, and limited functionality. Otherwise, the motor won't be able to handle the load.

Inverter system motor

The inverter motor is considered the most modern. It was invented and launched into production back in the 2010s, but it still remains head and shoulders above its competitors. The key is the inverter—a converter that can change the voltage frequency from alternating current to direct current. Thanks to this capability, it is independent of the power grid and can control the speed it picks up.

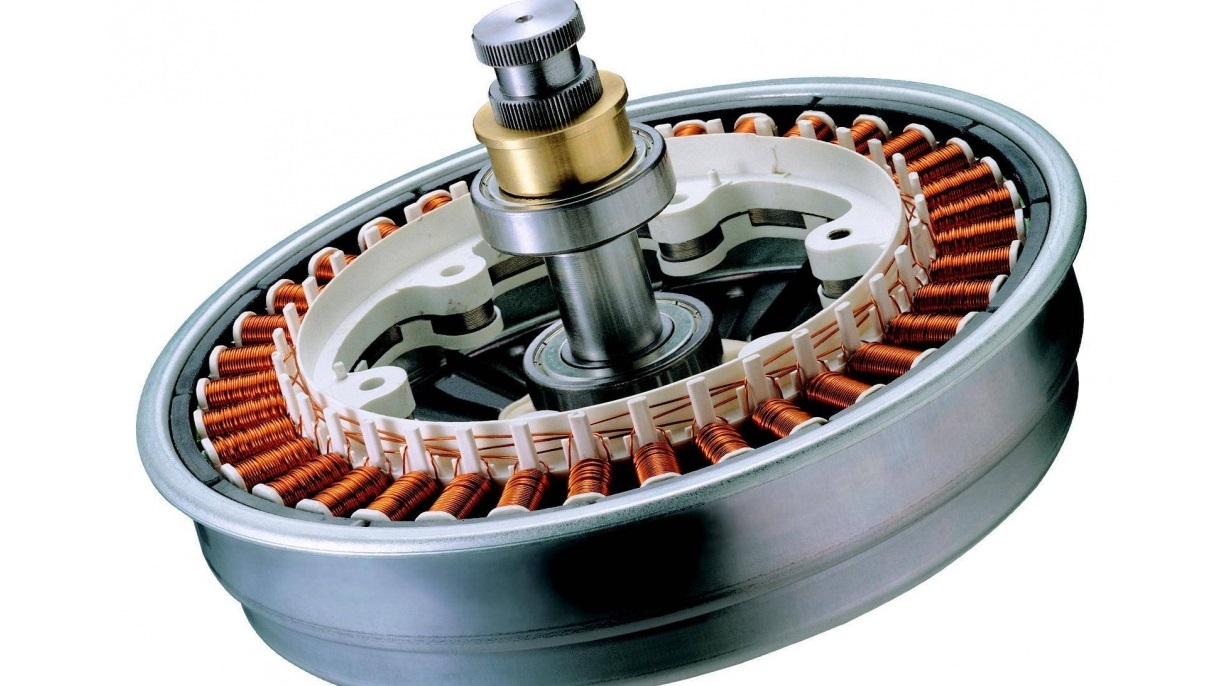

The technical name for an inverter electric motor is a three-phase brushless DC motor. The main components remain the same: a winding, a movable rotor, and a static stator with magnetic cores. These washing machines also feature a direct drive – a development of the company LG – direct connection of the motor to the drum, without electric brushes and belt drive.

Direct Drive technology, along with a brushless motor, is now found not only in LG washing machines. The idea has been adopted by other leading brands of large appliances, including Samsung, Hotpoint-Ariston, Siemens, Bosch, and Whirlpool.

Inverters are considered to be significantly better than commutator motors and asynchronous motors. Manufacturers and consumers alike cite the many advantages of direct drives, from compactness and quietness to durability and efficiency. But is this really true? Let's consider the main pros.

- "Inverter-powered washing machines are compact." Inverter motors, unlike their competitors, have smaller dimensions, but this is a minor difference in the overall size of the washing machine. The drum takes up most of the space, especially with a capacity of 6 kg or more. The absence of pulleys and belt drive frees up space, but only by a maximum of 3-5 cm in width and depth.

Direct Drive technology makes the washing machine more compact, reliable and quiet.

- "Motors without rubbing parts last longer." Yes, inverter motors don't have brushes, whose graphite tips wear down due to constant friction against the commutator. This eliminates the need for periodic brush replacement, making the inverter simpler and more reliable to operate. However, don't forget about the bearings—they're present, and they can also fail due to improper use of the machine.

- "The inverter is silent." Compared to brushed motors, which vibrate heavily and "hiss" due to brush wear, inverters are practically "silent". But absolute silence is out of the question—the mechanism hums faintly when in operation. The noise level can be compared to the squeak of a trolleybus. However, vibration is significantly lower, so direct-drive machines are quieter, don't shake or bounce around the room.

- "There's significant energy savings." Typically, machines with inverter motors are rated "A+++"—the lowest energy rating available. This advanced technology saves approximately 15% of energy. This involves stabilizing the speed, allowing the machine to adjust to the drum load, preventing unnecessary energy waste.

The main disadvantage of inverter motors is their high price. Their electrical circuits are complex to design, so they cannot be cheap.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment