How to make a grinder from a washing machine motor

Even the most basic sharpening machine costs money. It's essential, as scissors and, especially, knives, need to be kept in good condition. At the dacha, sharpened tools like pruning shears, shovels, axes, and others are needed even more frequently, and sharpening them by hand isn't an option—it's just a waste of time. You can build your own sharpening machine, especially if you have an old washing machine lying around. Here's how to make one, step by step.

Even the most basic sharpening machine costs money. It's essential, as scissors and, especially, knives, need to be kept in good condition. At the dacha, sharpened tools like pruning shears, shovels, axes, and others are needed even more frequently, and sharpening them by hand isn't an option—it's just a waste of time. You can build your own sharpening machine, especially if you have an old washing machine lying around. Here's how to make one, step by step.

What do we need to make the machine?

To assemble a home-made sharpening machine, you'll primarily need a working washing machine motor. You can use a 200-watt motor from a Soviet-era washing machine, such as the Riga-17 SMR-1.5. Although some say 400 watts is optimal, others say that using more than 300 watts can shatter the sharpening wheel. For occasional use of the sharpening machine, a motor of 1000 rpm is sufficient.

You won't need anything else from the washing machine; everything else will have to be turned or cut out of scrap materials yourself. Here's what you'll need:

- 2-2.5 mm thick metal for the sharpening casing;

- flange turning tube;

- grindstone;

- nut for securing the stone to the pulley;

- starting device;

- electric cable with plug;

- metal corner or wooden block for making the frame;

Preparing the flange

First, you need to make a flange or buy a ready-made one. It should match the diameter of the engine hub and fit the grinding stone securely. The flange is the transition piece between the engine and the grinding stone. If you're making it yourself from a piece of pipe, you'll need to cut a thread on one end, approximately twice the thickness of the pipe. A tap is used to cut threads.

The other end of the tube is pressed onto the motor shaft by heating, and then secured with welding or a bolt, drilling a through hole through the tube and shaft. Below is a drawing that can be used to machine the flange. Be sure to specify all diameters, according to your motor and grindstone, if you order this work.

When cutting threads and mounting the grinding wheel on the shaft, consider the direction in which the wheel will rotate. The threads should be opposite to the motor rotation to prevent the nut holding the wheel from loosening during operation.

Connect the engine and assemble the base

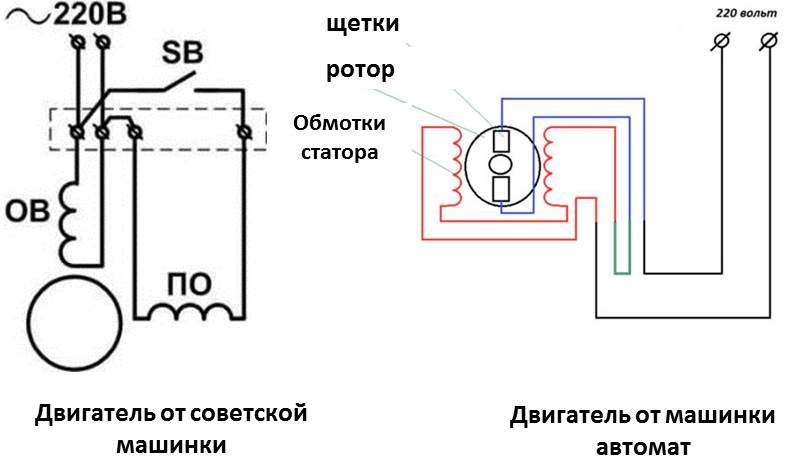

The next step is connecting the washing machine motor to an electrical cord with a plug. To do this, you need to locate the starting and running windings on the motor from a Soviet-era washing machine. To do this, use a multimeter and measure the resistance. The resistance of the working winding is 12 Ohm, and the starting winding is 30 Ohm. The terminals of the working winding are connected to the electrical cable. With this connection, the grinding wheel must be rotated manually. Therefore, many install a start button for this purpose.

A doorbell button can be used as a starting device, but not a regular capacitor. Connecting a capacitor will cause the washing machine's motor winding to burn out.

Using a washing machine motor eliminates the need for a start button. The grinder will work immediately after being plugged in. The diagram on the right shows such a connection. The most important thing is to correctly locate the motor's operating winding.

Important! When working with electricity, be careful. If you have any doubts about your abilities, consult a professional.

The last thing you need to make is a frame or base to mount the machine on. A protective guard over the grinding wheel is also essential, as the sharpening stone can throw off small pieces and dust. The protective cover is best made of 2-2.5 mm thick metal, although there are also homemade machines with protection made of thick plastic. The stand can also vary, but the most reliable is made of angle iron. Some mount the machine to the wall, while others prefer a portable sharpener.

That's the beauty of a homemade sharpener: you can customize it to your liking, making it comfortable to use. The photos show some examples of homemade machines.

A sharpening machine is one of the most common DIY devices made from a washing machine motor. You can make anything you want out of such a part, even honey extractorBut you need to be careful not only when making such equipment but also when using it, to avoid harming your health. Good luck!

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment