How is a washing machine drum constructed?

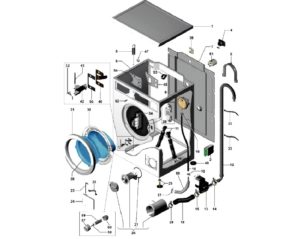

Laundry is loaded into the washing machine through the drum. At first glance, its design is simple: a cylindrical metal tank with perforated walls and fin-like paddles. However, technicians understand this not only as the cylinder, but as the entire drum assembly—the tank, seal, drive, spider, and other adjacent components. For complete repairs and safe operation, it's essential to understand the structure of the washing machine drum. We'll explore all the components, their locations, and their purposes.

Laundry is loaded into the washing machine through the drum. At first glance, its design is simple: a cylindrical metal tank with perforated walls and fin-like paddles. However, technicians understand this not only as the cylinder, but as the entire drum assembly—the tank, seal, drive, spider, and other adjacent components. For complete repairs and safe operation, it's essential to understand the structure of the washing machine drum. We'll explore all the components, their locations, and their purposes.

The main unit of the machine

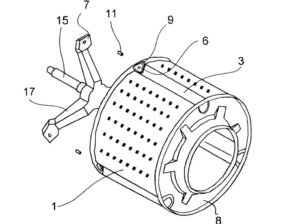

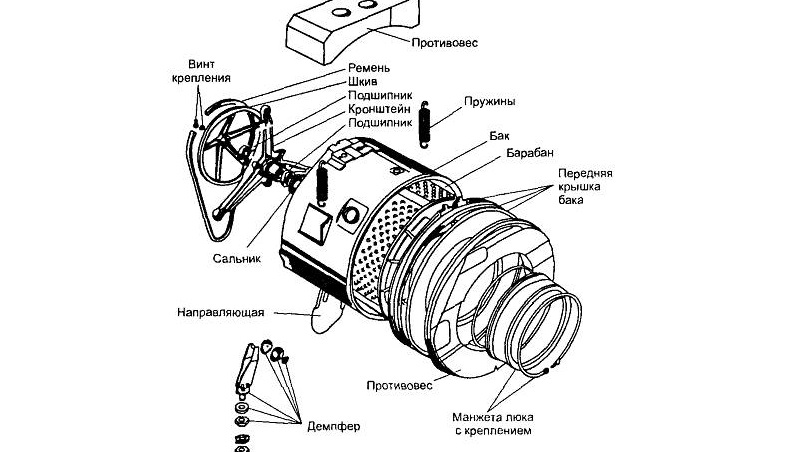

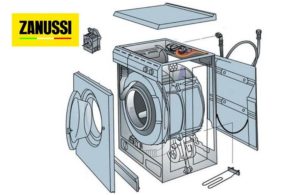

The drum is the key element of the washing machine, and almost all parts of the machine interact with it. The stainless steel cylinder is the part of the unit visible to the user, through which laundry is loaded into the machine. Front-loading washing machines have an entrance at the front, while top-loading machines have an entrance at the top. Dirt is removed thanks to the special design of the tank: perforations in the walls allow water to enter, while a rubber seal and door ensure a proper seal.

The remaining components of the unit are "hidden" from the user's view. The first is the tank, which houses the drum. This large, lightweight, and durable container is attached to the top of the detergent drawer hose, and the drain pipe is connected to the bottom. The cylinder is connected to the tank at the rear by a metal crosspiece, bushing, and bearings.

The drum is built into the tank, where it is held by a crosspiece, and rotates thanks to an axle, drive and motor.

The system's rotation is provided by a shaft receiving impulses from the motor. The motor is located under the wash tub and can be either a commutator or inverter type. The motor accelerates to a preset speed, which is transmitted to the cylinder via a direct drive or a pulley and belt. Acceleration speed is monitored by a Hall sensor.

Vibration emanating from the motor is dampened by the built-in shock absorbers. The tank and drum are suspended by springs and vibration dampers. The containers are securely but not rigidly mounted, maintaining the flexibility and elasticity of the assembly. Centrifugal force is also compensated for by counterweights—concrete blocks that add tens of kilograms to the machine's weight.

Next to the drum cylinder, at the rear of the tank, there's a hole for the tubular electric heater, which heats the water to the desired temperature. Heat is generated by a coil located directly in the wash tank, and the contacts are routed to the outside and protected by a sealed gasket. A temperature sensor monitors the heating level and transmits data to the control module.

In some machines, the location of the main components may vary - it all depends on the manufacturer and model. To find out more precisely how a specific washing machine works, just look at the manufacturer's instructions.

What types of drums are there?

Every washing drum is made of stainless steel. This material was chosen for a reason: stainless steel is strong, durable, and corrosion-resistant. This ensures a long service life for the appliance.

The drum's interior surface is perforated with numerous holes. Through these holes, water and detergent reach the laundry and drain into the drain after washing. However, these holes also have a downside: as the drum rotates, the fabric is pressed against them, causing abrasion and damage to the fibers.

It is recommended to choose washing machines with improved drums: drip, pearl or honeycomb.

Manufacturers are currently trying to avoid damaging contact between items and the perforated drum walls. Developers are refining the cylinder's rotation principle and improving its design. This research has resulted in the development of various types of washing containers.

- Perforated drums. These are found in budget washing machine models, as these cylinders have smooth walls with numerous standard holes. The interior surface is flat, which negatively impacts the laundry.

- Drip cylinders. This technology is called VarioSoft, and it was developed and tested by Bosch. The name speaks for itself: the inner surface of the drum is "strewn" with drop-shaped holes. The key to this design lies in the protrusions themselves: one side of the holes is flat, while the other is raised. As a result, laundry lands on either the smooth side or the sharp side, depending on the selected cycle. Delicate fabrics are washed gently, while the intensive cycle produces harsher abrasion.

- Pearl Drums. Pearl Drum technology from Hansa designers. These cylinders are perforated with various-sized, pearl-shaped hemispherical holes. The rounded shape keeps laundry away from sharp edges, protecting fabrics from wear even when the drum spins at up to 1,400 rpm.

- Honeycomb containers. The patent for the innovative honeycomb-shaped perforation belongs to the company Miele – you won’t find it on other machines. These drums are lined with raised, stamped hexagons. These holes are much smaller in diameter than standard, drip, or pearl drums, preventing fabrics from getting caught in them. This ensures gentle washing. The small holes also keep the detergent near your clothes longer and prevent foreign objects from falling into the drum.

The drum type is crucial: the wider the holes and the smoother the cylinder surface, the faster the detergent is washed out and the more wear and tear is applied to the laundry. If you frequently wash delicate items, it's recommended to choose honeycomb, drip, or pearl drums. These will protect your clothes from damage, color fading, pilling, and snagging.

Related details

Washing machine owners don't need to know what a drum looks like in cross-section. It's enough to understand the cylinder's relationship to the other system components—from the powder receptacle to the motor. This principle is the same for all washing machines, both front-loading and top-loading. The key is to consider all the "participants" in the washing process.

- The dispenser drawer. Designed for adding detergent, it's commonly referred to as the powder compartment. It's typically located in the upper left corner of the machine and has three compartments: for additional liquids, the main wash, and the prewash. The compartment's purpose can be identified by its special markings. Water flows through hoses to the detergent, and then the soap solution flows through pipes into the drum.

- Seal. This is the rubber band that encircles the drum at the front, behind the hatch door. More precisely, there are two seals: one on the drum body, and the other on the wash tank. The double rubber layer ensures a watertight seal, preventing water from leaking out.

The electronic lock is released automatically 2-3 minutes after the end of the cycle.

- Hoses and pipes. Water coming from the pipes passes through the dispenser via rubber grooves and is poured into the drum, where it joins the dirty laundry. After washing, the waste liquid is discharged through drainage pipes into the sewer system, where it is pumped out.

- Pump. The pump drains dirty water from the drum and tank into the sewer. The drainage system is simple: a motor starts the mechanism, and a rotating impeller directs the flow. Everything is mounted on a volute, where the drain hose is connected to the pump. The drain hose often gets clogged with debris, hair, and other objects like children's socks, hairpins, and keys that get caught in the machine.

- UBL. This is a hatch locking device, or, in simple terms, an electronic lock. It activates automatically after the cycle starts, locking the hatch door. The system "block" prevents the user from opening the drum during washing, which eliminates the possibility of accidentally opening the machine when it is full of water.

- The inlet valve. Its job is to fill the drum with water from the mains. It consists of three coils and a membrane that opens and closes in response to electrical impulses. These impulses are sent to the valve by a module based on data from the pressure switch.

- A pressure switch. It's a plastic "box" with a long tube lowered into the washing machine's tub. The sensor measures the pressure in the tank, displaying the water level. This allows the control board to control the filling and draining process.

- Surge protector. The capacitor ensures system safety by protecting the wiring and mechanisms from power surges. The surge protector is capable of balancing the current flowing into the machine, preventing the internal wiring from overheating and short-circuiting.

- The control board. This is the "brains" of the machine, using electronics, triacs, tracks, and resistors to control the system. The module issues commands, monitors their execution, and, in the event of a breakdown or malfunction, urgently stops the cycle.

The drum of a washing machine is a key component, as it is where the laundry is washed. All other components interact with it in one way or another: they fill, spin, and stop the load, ensuring a high-quality wash.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment