How does the drum of an Indesit washing machine work?

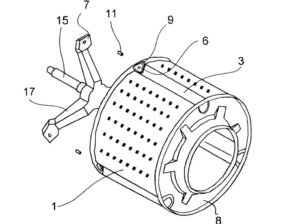

The drum itself in Indesit washing machines is virtually identical to similar parts in other washing machines. It looks like a movable cylindrical tank with holes and ribs on the walls, is made of metal, and serves to load laundry into the machine. However, the drum design of an Indesit washing machine often refers to more than just the cylinder. It encompasses the entire drum assembly, including the tub, seal, shaft, and many other components. We'll discuss each of these below.

The drum itself in Indesit washing machines is virtually identical to similar parts in other washing machines. It looks like a movable cylindrical tank with holes and ribs on the walls, is made of metal, and serves to load laundry into the machine. However, the drum design of an Indesit washing machine often refers to more than just the cylinder. It encompasses the entire drum assembly, including the tub, seal, shaft, and many other components. We'll discuss each of these below.

Construction of the tank-drum unit

The drum is the central component of a washing machine, and most of its components interact with it in one way or another. Once again, its design is simple, consisting of a cylindrical stainless steel container. The user places dirty laundry through the main opening, and water then enters the tank through special holes. The water doesn't escape further—a tightly closed door and rubber seal ensure a watertight seal.

The drum is housed in a tank—a large, lightweight, and durable plastic container. Its top has a hole for the dispenser hose, which delivers water and detergent to the laundry, and a drain pipe runs underneath for the subsequent drainage of the used liquid. The pressure switch tube is also located here. The tank-drum unit is connected at the back, through a screwed metal crosspiece with a sleeve and bearings. The design is then supplemented with a shaft, driven by a pulley and drive belt.

The drum is suspended in a plastic tank and rotates using a crosspiece and shaft.

While the drum is supported by a spider, the tank is secured in the machine by a shock-absorbing system consisting of springs, shock absorbers, and dampers. Due to centrifugal force, the tank is not rigidly but securely mounted. A concrete counterweight is also essential to compensate for vibrations generated during the wash cycle.

Next to the drum, at the rear of the tank, there's a hole for the heating element. The heating element is bolted in place with its contacts facing outward and heats the water to the set temperature. A special sensor, a thermistor, helps with this, transmitting heating data to the control board. Liquid itself doesn't come into contact with the heating element's contacts, as the space around it is securely sealed with rubber gaskets.

A commutator-type motor is located at the bottom of the tank. It accelerates the drum, transmitting the accumulated speed from the hub to the pulley via a drive belt. A special sensor, a tachogenerator, monitors the motor speed.

Parts adjacent to the tank

But the average user doesn't need to know what a drum looks like in cross-section. It's much more important to understand the relationship between the main wash tank and the rest of the machine's components and their purpose. In short, the cylinder directly interacts with the following elements:

- Dispenser. Simply put, it's a compartment where the detergent is poured. Typically, there are three compartments in the drawer: one for the main wash, one for the pre-wash, and one for the fabric softener. The drawer is located in the bin, where the hoses from the filler spout are connected. The incoming water is saturated with powder or gel and sent through hoses to the drum.

The purpose of the dispenser compartment is determined by the applied image: the container for the conditioner is marked with an “asterisk”, the main wash is marked with the number “I”, and the pre-wash is marked with “II”.

- Cuff. This is a rubber seal located on the hatch and necessary to ensure a watertight seal inside the machine. There are two rubber seals: one attaches to the body, and the other to the tank.

- Hoses and pipes. This is simple, as water from the water supply enters the drum through the upper pipes, where it mixes with the detergent as it passes through the dispenser. The lower pipes drain the waste liquid through a special sleeve directly into the sewer.

- Pump. Water drained through the bottom outlet enters the pump, which sucks the dirty liquid out of the drum. The drainage system is standard: a motor inside, an impeller in front, and a volute and drain hose on top. However, clogging is highly likely, as any foreign objects that get into the washing machine—hair, coins, and bra underwire—reach the pump and cause a blockage.

To avoid blockages, carefully check pockets before loading items into the drum, or better yet, use special protective bags.

- HLD stands for Door Locking Device and is an electronic lock. It complements the mechanical door locking system and is automatically activated after the washing program is started.

- Inlet valve. Consists of 1-3 coils that, when electrically energized, open the hose, allowing water to flow into the machine. Once sufficient water has been drawn in, the membrane closes, and the inlet stops.

- Pressure switch. The sensor consists of a plastic box and a long tube extending deep into the machine. The device monitors the pressure in the tank by measuring the level of water collected.If the set point is reached, the pressure switch sends a corresponding signal to the control board, and water intake stops.

- Surge protector. Ensures safe operation of the machine by protecting internal components and electronics from power surges. The device suppresses pulsed and high-frequency interference, reducing the risk of overheating and short circuits.

- The control module. The "brains" of the Indesit washing machine, which uses triacs and resistors to control all the machine's components. The board sends commands, monitors their execution, and in the event of a breakdown or malfunction, automatically terminates the cycle.

If the control board fails, the machine will not turn on and will not respond to user commands.

The washing drum is part of a well-oiled machine. Almost every part of the machine interacts with the drum in one way or another, ensuring safe and high-quality washing.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment