LG washing machine pump design

The washing machine's drainage system is responsible for emptying the drum. When the control module signals, the pump starts and pumps the waste liquid into the sewer. If the pump malfunctions, the process is disrupted, and water remains in the washing machine.

The washing machine's drainage system is responsible for emptying the drum. When the control module signals, the pump starts and pumps the waste liquid into the sewer. If the pump malfunctions, the process is disrupted, and water remains in the washing machine.

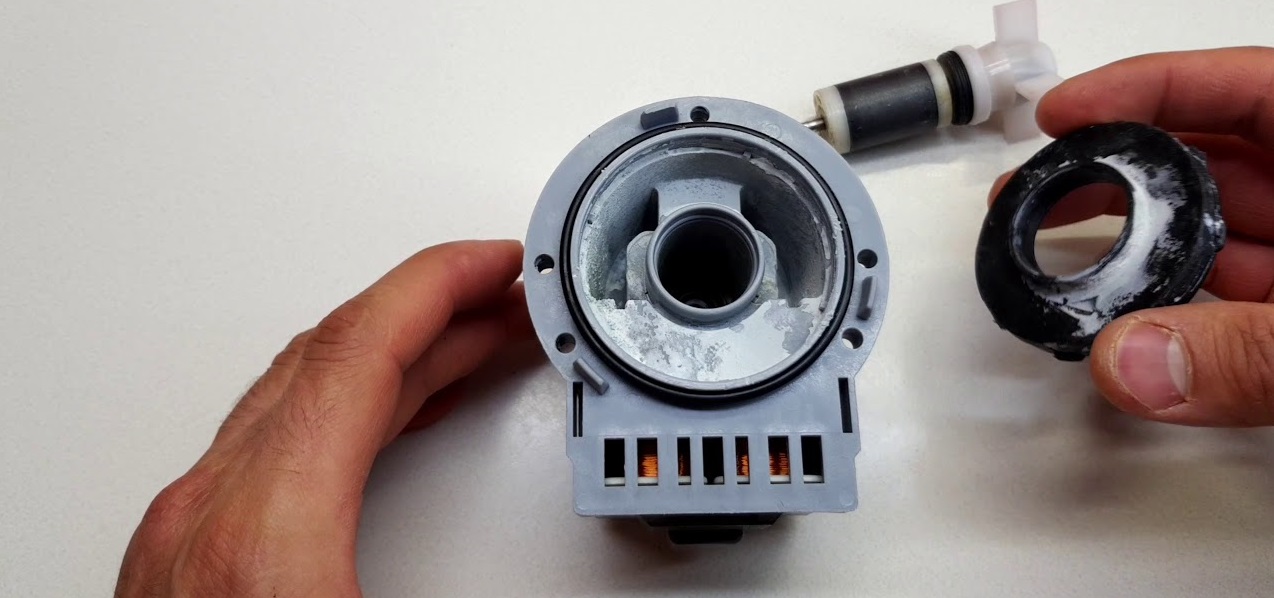

To promptly respond to a backed-up drain and fix the problem, you need to understand the design of your LG washing machine's drain pump. Knowing the components allows you to disassemble, clean, and replace it yourself. Let's take a look at the design of a standard pump.

Let's take the pump apart piece by piece

Knowing how the drain pump works on direct-drive machines allows you to clean it yourself if it becomes clogged. Even if it fails and needs replacing, understanding its design will make it easier to find the right parts. When choosing a new pump, you need to consider three important aspects: the power of the part, the mounting method, and the contact diagram.

The pumps used in modern LG direct drive washing machines differ from each other:

- rated power (from 25 to 40 W);

- method of fastening to the snail (bolt or plastic latches);

- contact diagram (separate or double terminals);

- type (circulation or simple).

Pumping stations also differ in their filtration type. Pumps are typically equipped with spiral filters. Their main drawback is that when clogged, liquid stagnates inside the element and begins to smell. In this situation, you have to disassemble the housing, remove the nozzle, and clean the element of accumulated dirt.

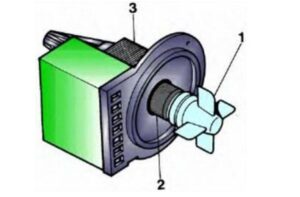

The drain pump consists of a plastic casing, a rotor, an impeller, a pair of windings and a core magnet.

The pump's operating principle is quite simple. It functions like an asynchronous motor—it has both moving and static elements. The pump starts after receiving the appropriate signal from the electronic board. The operating algorithm is as follows:

- the control module gives the start command;

- the rotor (a cylindrical magnet) starts to rotate;

- the pump impeller is driven (it is fixed on the shaft);

- The impeller blades set the desired direction of movement of the pumped water.

As for the magnet core and a pair of windings, they remain static. These elements help the system function.

This is how the simple drain pump found in LG washing machines starts. Due to their simple design, these components rarely break. Typically, malfunctions are caused by a blockage inside the housing or a chipped impeller. Less commonly, the magnetic core weakens.

Circulation pumps can only flow liquid in one direction, pushing it toward the outlet. These components are found on newer LG washing machines. On more expensive models, the pump is additionally equipped with a rubber seal. The seal seals the fitting and prevents water from getting into the drum bearings.

Modern circulation pumping stations feature a rotor shaft that passes through a central rubber bushing. The structure is additionally treated with a moisture-resistant lubricant. The sealant fills all possible gaps, ensuring smooth and quiet rotation of the mechanism. This know-how extends the service life of the part.

Let's describe the operation of the pump

The drain pump operates every time the washing machine is started, regardless of the selected mode. If the pump does not turn on, the machine will remain standing with a full tank of soapy waste water. The part is not activated immediately, but closer to the end of the cycle, before rinsing and during spinning.

To understand how the pump works, it's important to remember how the laundry process works. First, the user loads the laundry into the drum, pours detergent into the dispenser, and selects the appropriate wash program. After the machine starts, the control module is activated. The following steps then occur:

- the inlet magnetic valve opens;

- water is poured into the detergent drawer, mixing with the powder;

- soapy liquid flows into the tank;

- The pressure switch controls the water level in the centrifuge;

- When enough water is collected, the machine starts washing.

The "pump station" is activated not at the very beginning of the program, but rather toward the end, before rinsing, and then during the spin cycle. The pump, receiving a signal from the main electronic module, begins to drain the water from the tank, either completely or partially.

Removing the soapy waste from the washing machine tank is done as follows:

- the pump is activated, the impeller is set in motion;

- water leaves the tank through the drain pipe;

- the waste liquid flows further and passes through the filter element;

- water ends up in the drain pump and flows through it;

- soapy water is removed into the sewer through the drainage hose;

- The pressure switch monitors the water level in the tank;

- When the tank becomes empty, the level sensor notifies the control module.

The pump is installed at the bottom of the washing machine body – this is necessary to ensure unimpeded drainage of water from the system.

If your machine isn't draining wastewater from the tank, you'll need to check the drainage system. If the pump is clogged, cleaning it will help. If the pump burns out, repairing it isn't practical; you'll need to purchase and install a new one.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment